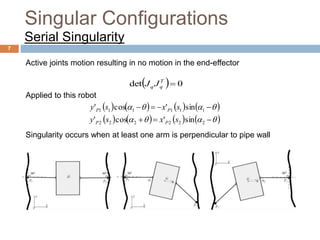

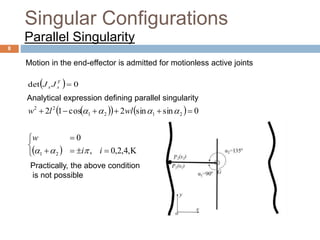

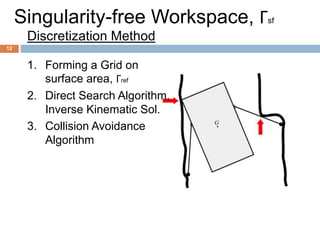

A mobile parallel robot used for pipeline inspection is analyzed. The robot consists of single modules resembling a snake. The study determines the robot's singularity-free workspace and derives optimal geometric parameters. When passing through sharp corners in the pipe, the robot encounters singular configurations that disrupt mobility. To overcome this, prismatic joints are added to the arms, allowing continuous singularity-free motion across corners through optimal control strategies like path following control and gradient ascent to maximize arm length. Simulation results demonstrate the robot can navigate corners without getting stuck, leading to a continuous singularity-free workspace.

![Snake-like Pipeline Inspection

Robot

Explorer 10/14 [Photograph]. Retrieved 11 December, 2013, from Pipetel technologies

Inc. http://www.pipetelone.com/explorer_10-14.html

2](https://image.slidesharecdn.com/35db5ad6-1d93-4fc7-acfe-0d1c364b8065-160404144025/85/Hassan-Thesis-Presentation-Dec16-2-320.jpg)

![Contribution

Analysis of a single module of a snake-like

pipeline inspection robot.

Study of Workspace and Singularities

Determination of Optimal Geometry

Optimal Control in a Geometrically Singular pipe

Explorer 10/14 [Photograph]. Retrieved 11 December, 2013, from Pipetel technologies

Inc. http://www.pipetelone.com/explorer_10-14.html

4](https://image.slidesharecdn.com/35db5ad6-1d93-4fc7-acfe-0d1c364b8065-160404144025/85/Hassan-Thesis-Presentation-Dec16-4-320.jpg)

![Step 1:

Step 2:

]0[l ]0[w ]0[h ]0[a

0001 ,,,Fmax ahwll

ldl

]1[l

Optimization of Geometric

MethodOptimization Technique: Parametric Variation

32](https://image.slidesharecdn.com/35db5ad6-1d93-4fc7-acfe-0d1c364b8065-160404144025/85/Hassan-Thesis-Presentation-Dec16-32-320.jpg)

![Step 1:

Step 2:

]0[l ]0[w ]0[h ]0[a

0001 ,,,Fmax ahwlw

wdw

]1[l ]1[w

Optimization of Geometric

MethodOptimization Technique: Parametric Variation

33](https://image.slidesharecdn.com/35db5ad6-1d93-4fc7-acfe-0d1c364b8065-160404144025/85/Hassan-Thesis-Presentation-Dec16-33-320.jpg)

![Step 1:

Step 2:

]0[l ]0[w ]0[h ]0[a

ahwla

ada

,,,Fmax 0001

]1[l ]1[w ]1[h ]1[a

Optimization of Geometric

MethodOptimization Technique: Parametric Variation

34](https://image.slidesharecdn.com/35db5ad6-1d93-4fc7-acfe-0d1c364b8065-160404144025/85/Hassan-Thesis-Presentation-Dec16-34-320.jpg)

![Step 1:

Step 2:

Step 3: Repeat the above process

]0[l ]0[w ]0[h ]0[a

]1[l ]1[w ]1[h ]1[a

qq 1

][ql ][qw ][qh ][qa ][q

Optimization of Geometric

MethodOptimization Technique: Parametric Variation

35](https://image.slidesharecdn.com/35db5ad6-1d93-4fc7-acfe-0d1c364b8065-160404144025/85/Hassan-Thesis-Presentation-Dec16-35-320.jpg)