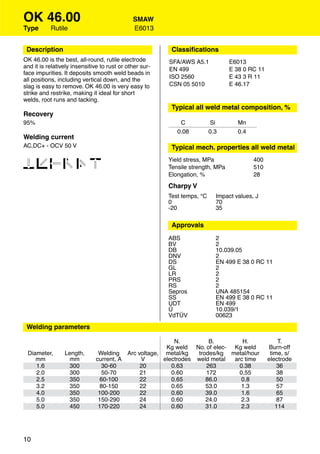

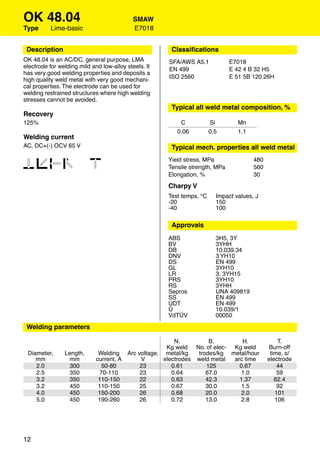

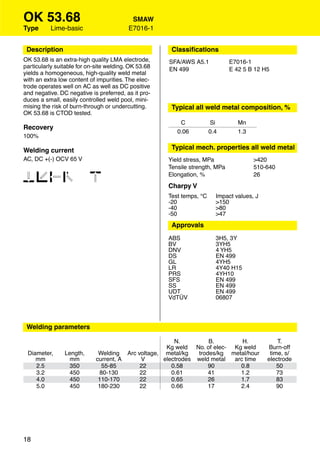

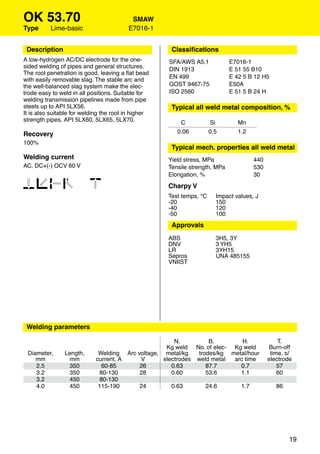

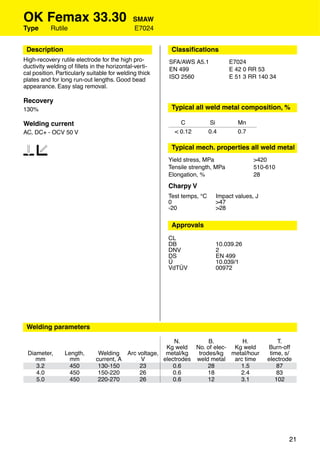

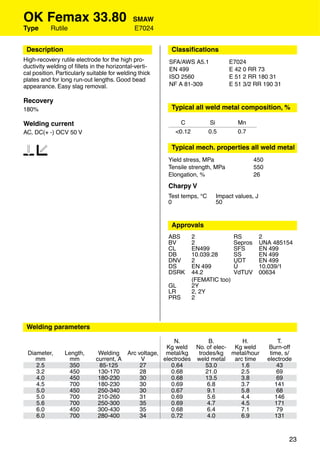

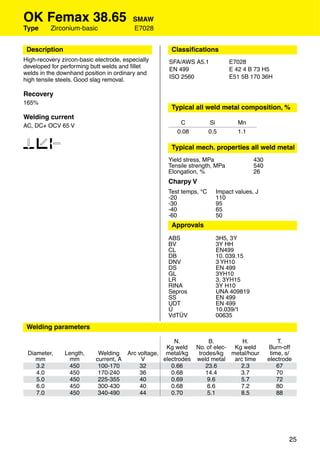

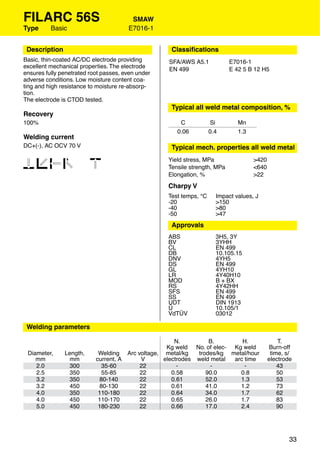

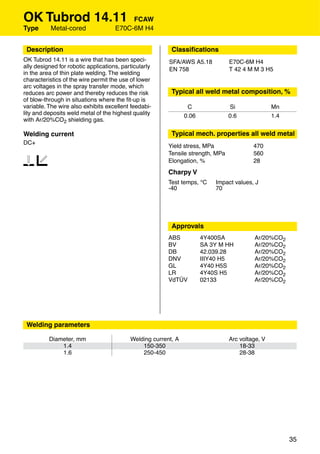

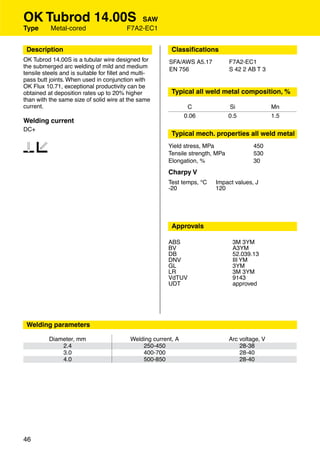

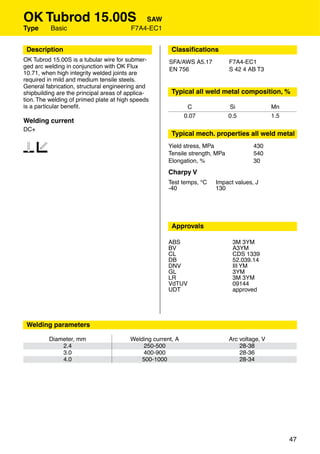

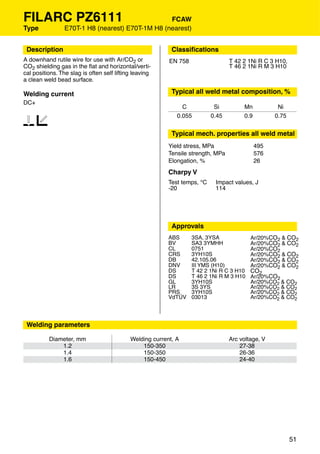

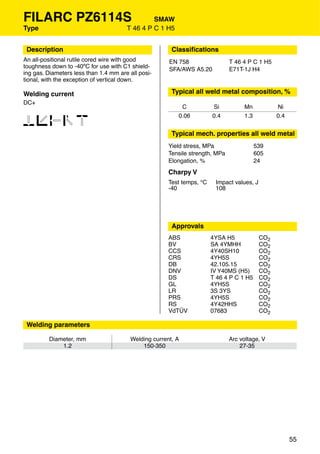

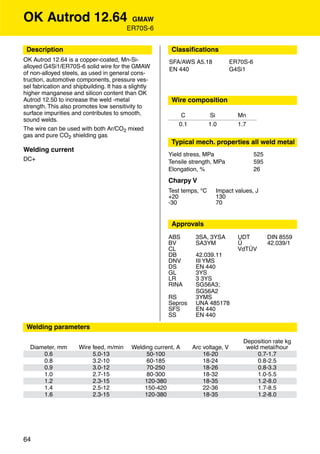

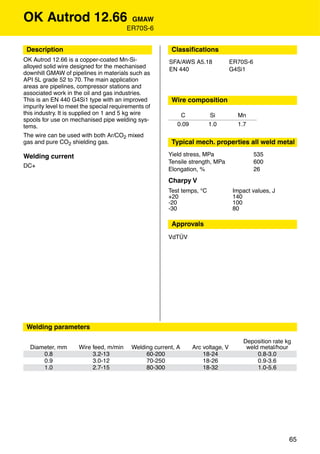

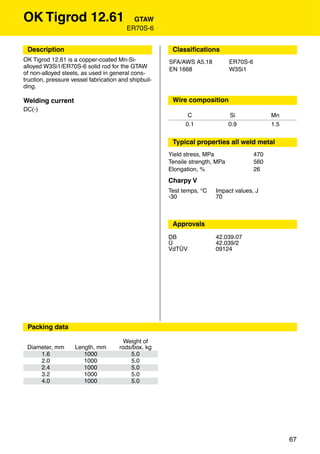

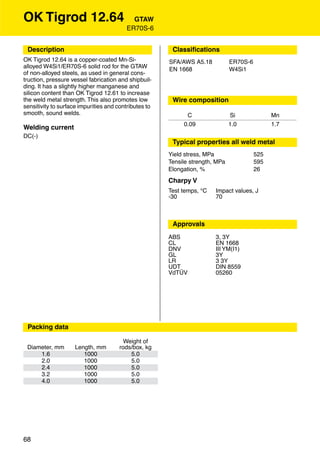

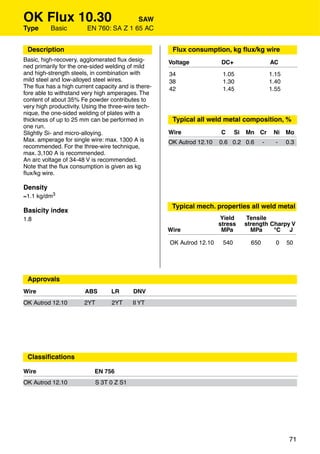

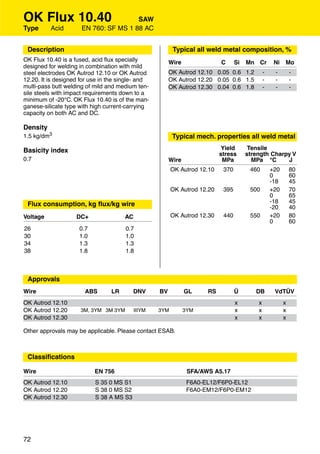

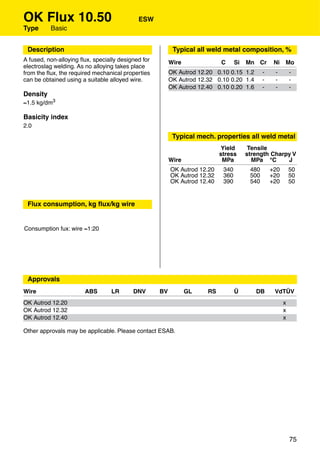

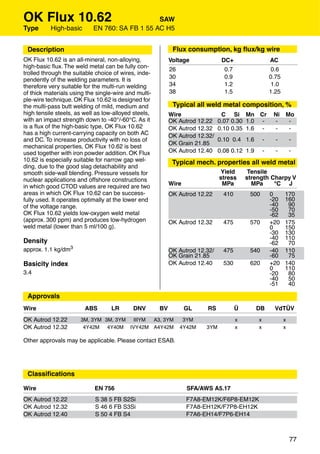

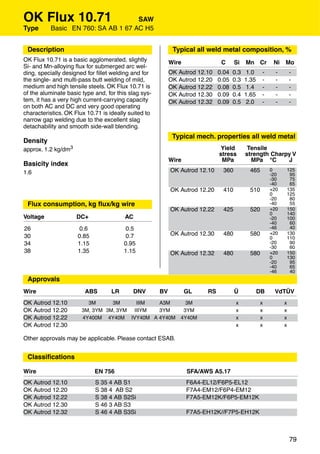

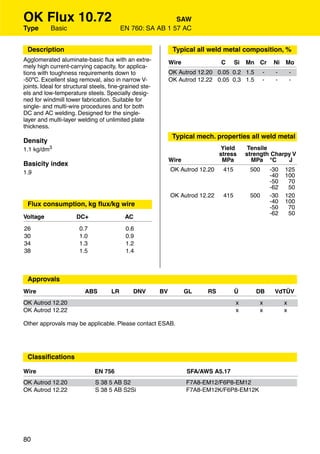

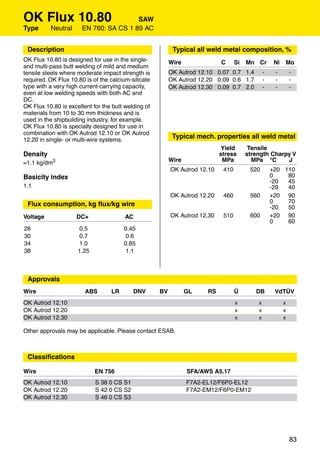

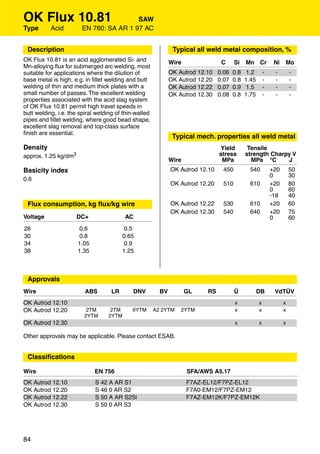

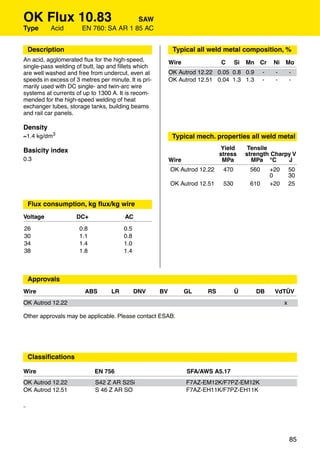

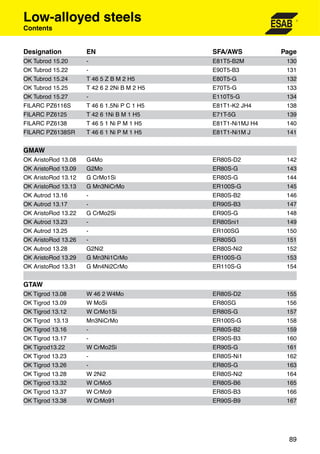

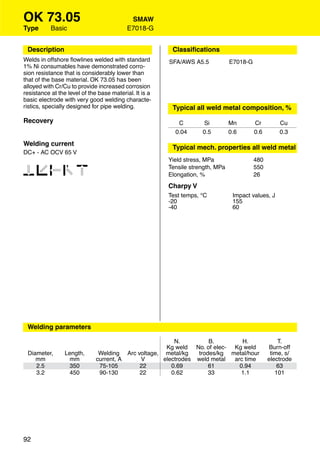

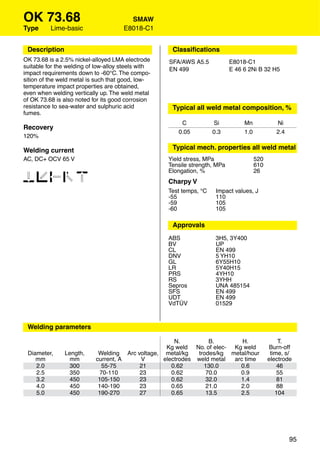

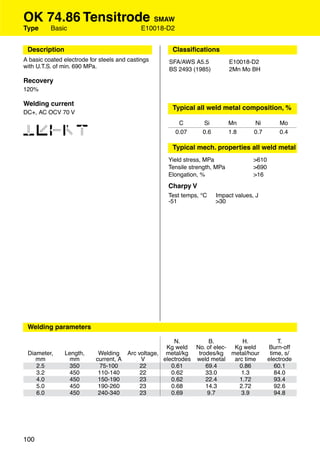

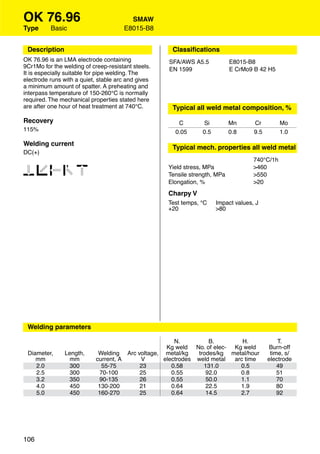

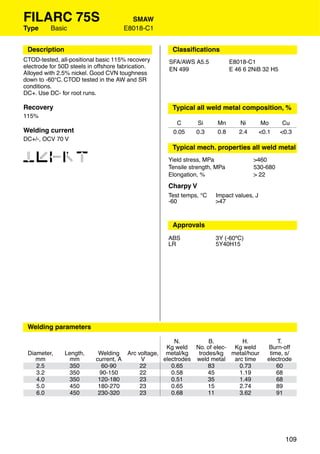

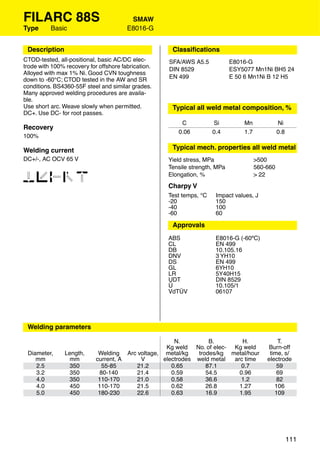

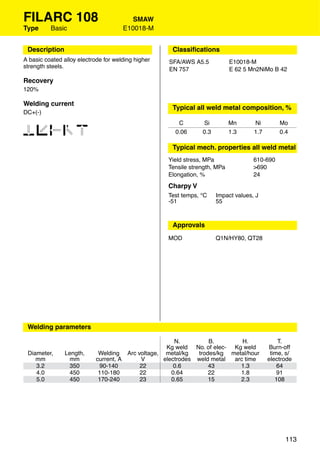

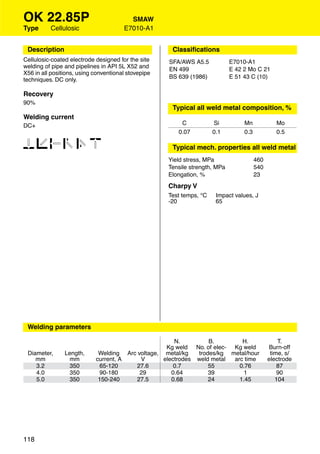

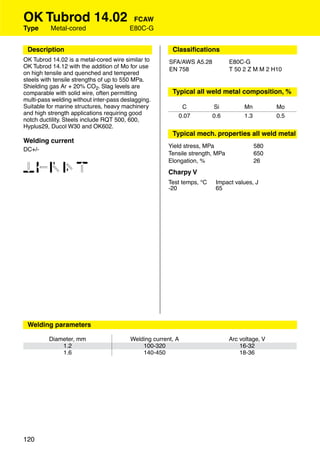

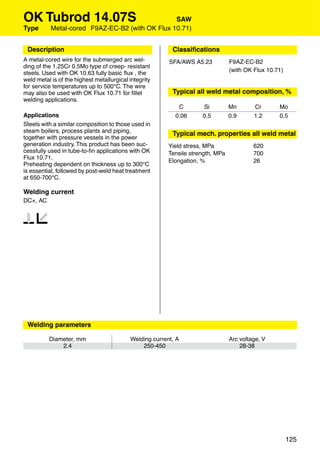

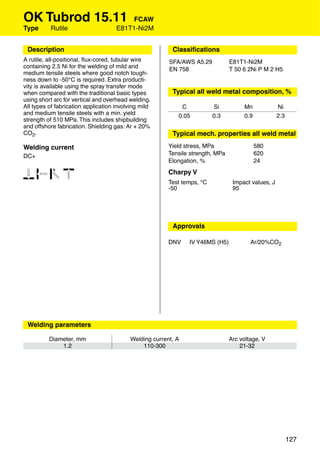

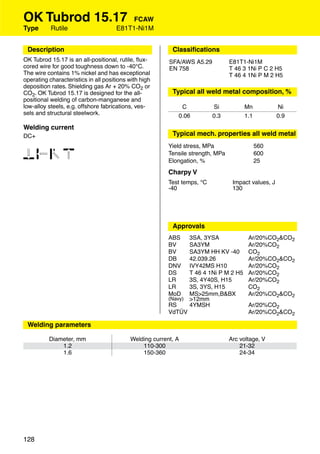

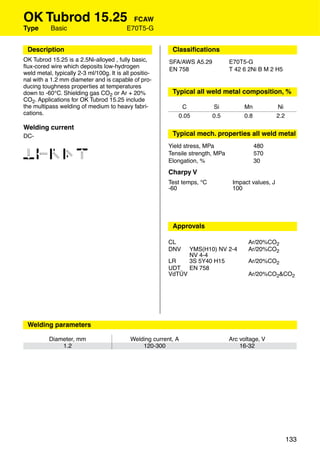

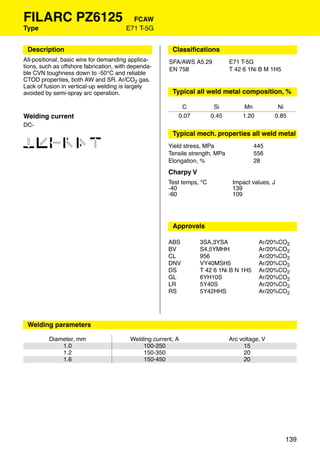

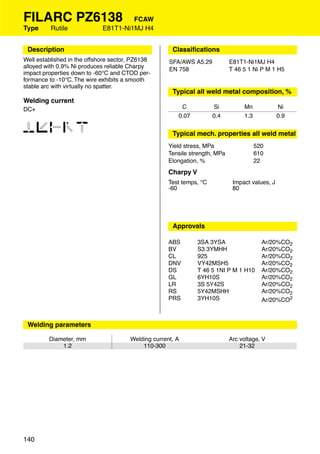

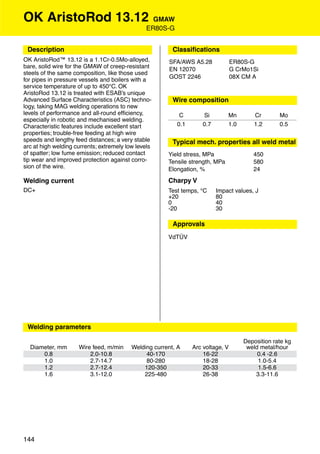

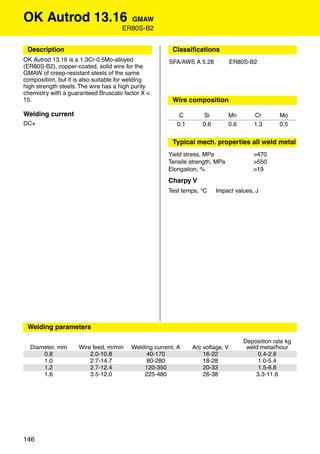

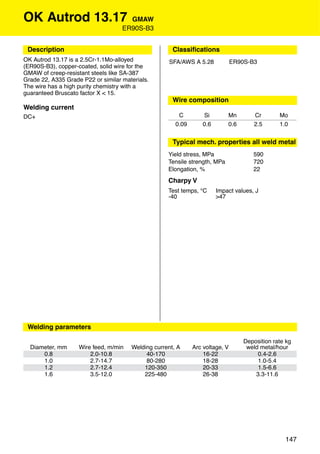

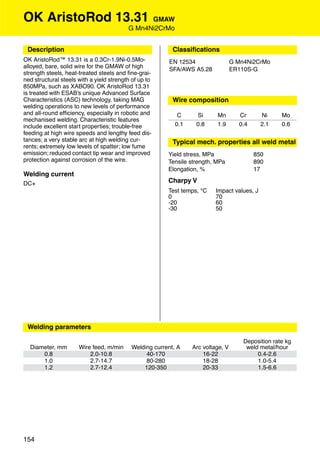

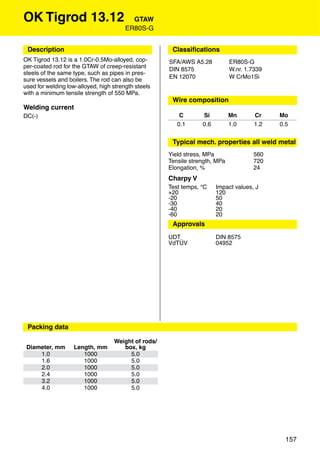

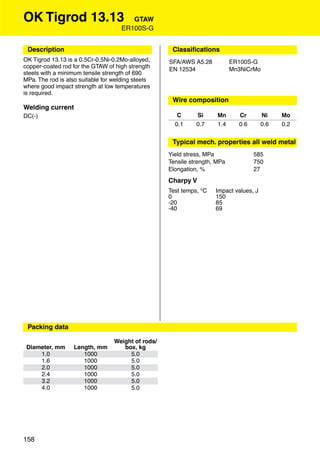

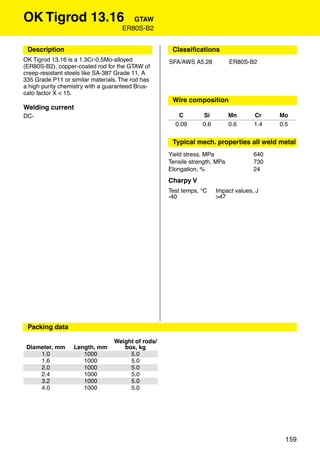

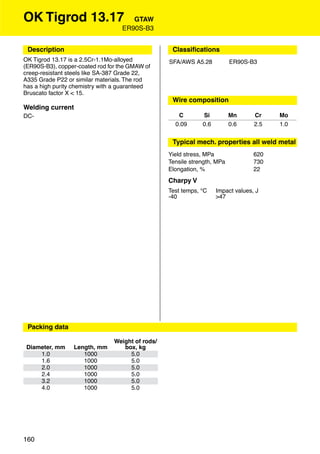

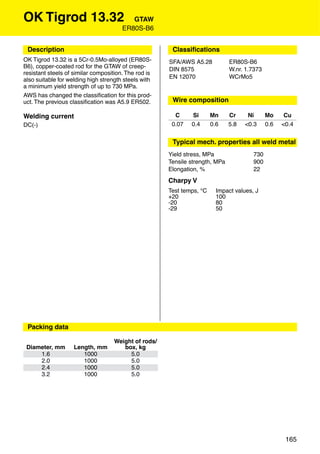

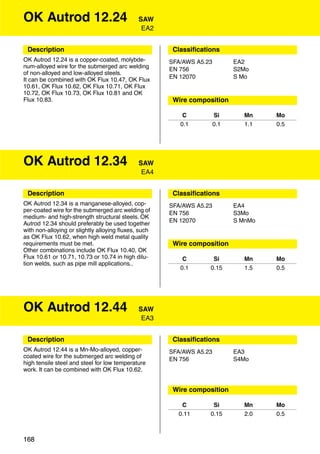

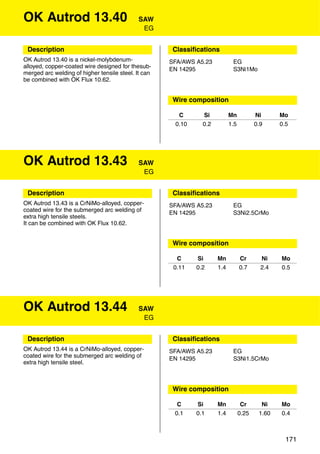

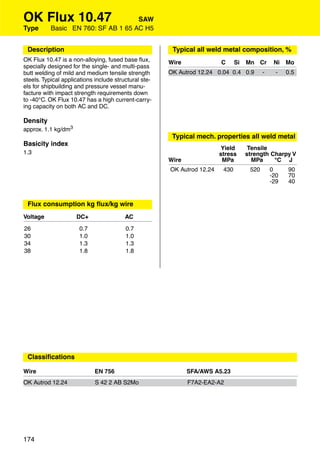

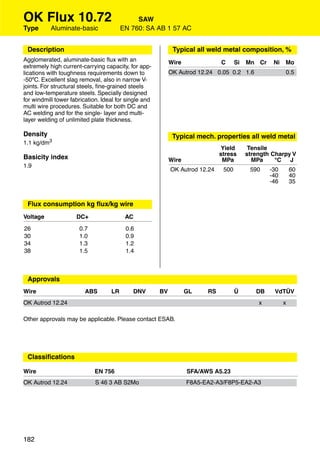

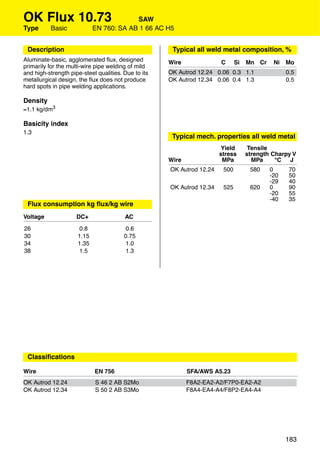

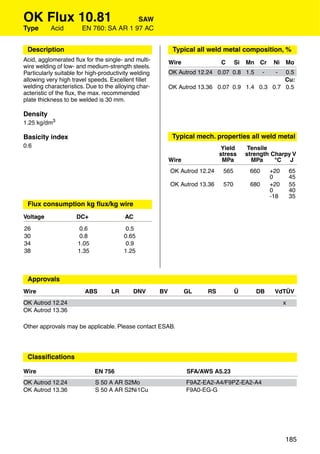

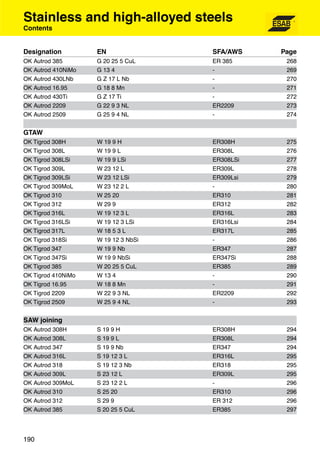

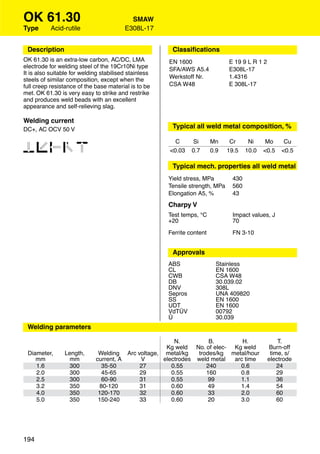

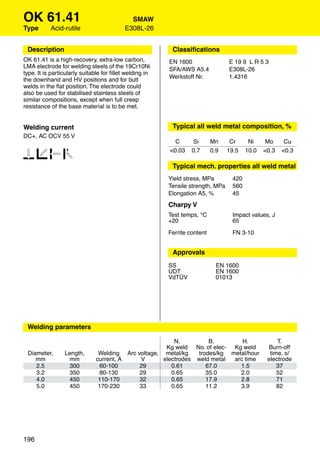

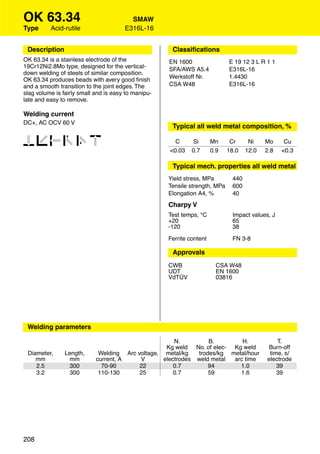

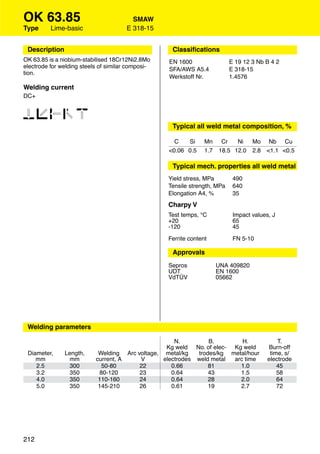

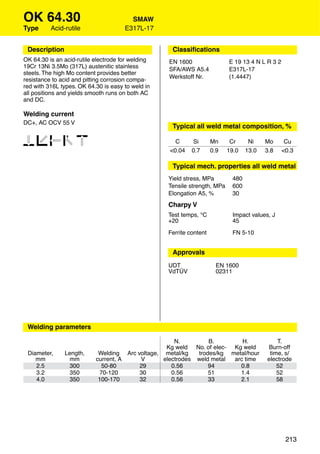

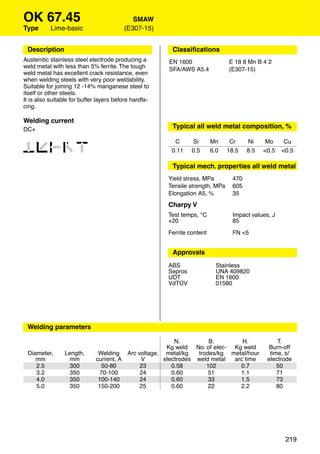

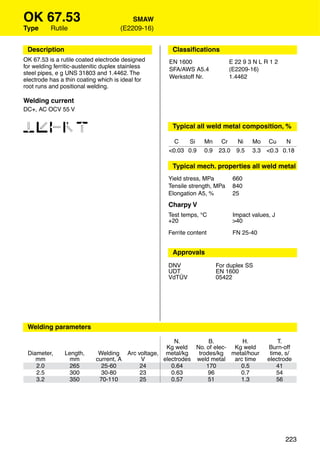

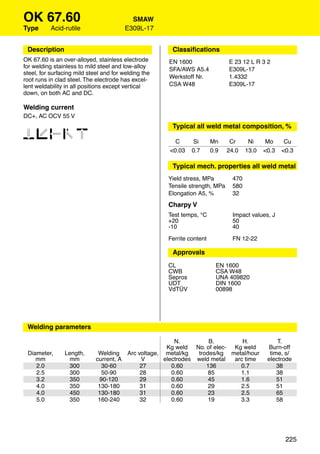

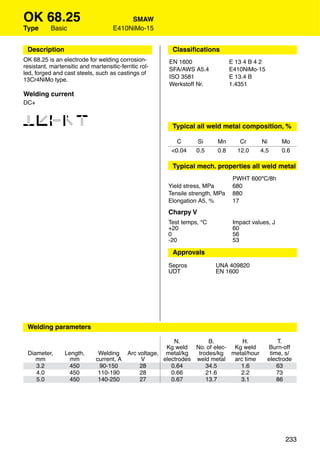

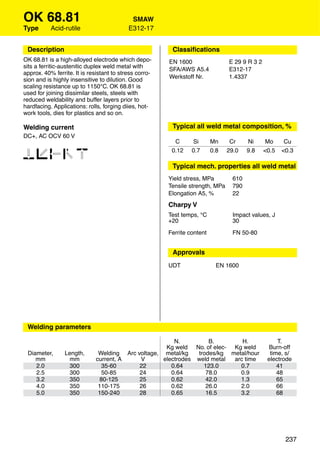

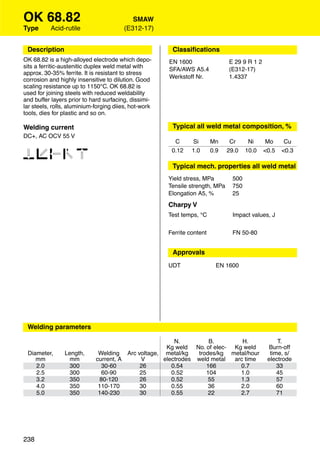

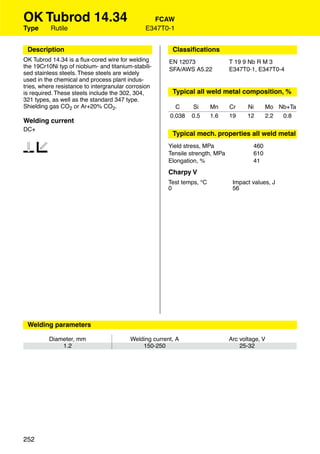

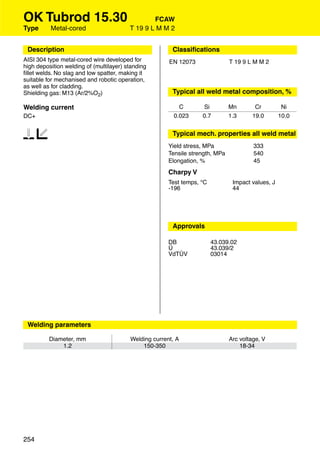

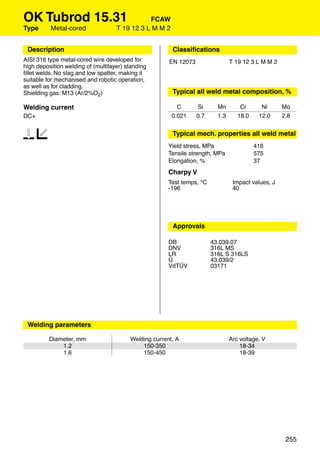

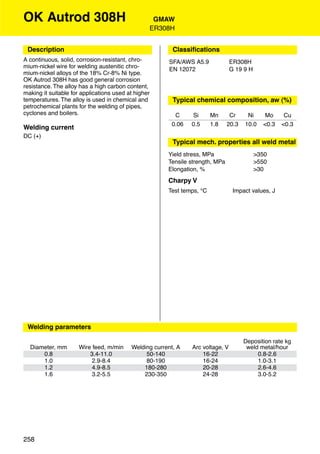

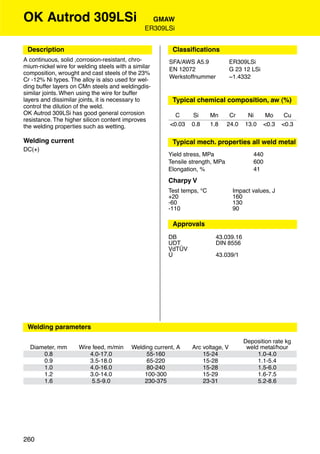

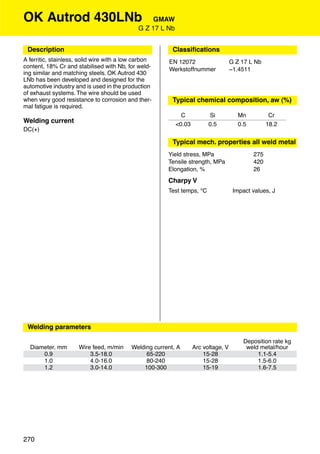

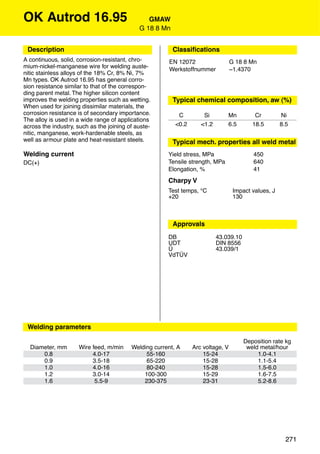

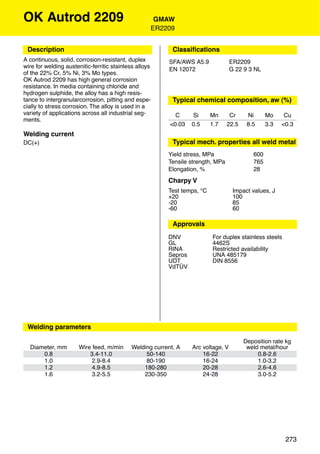

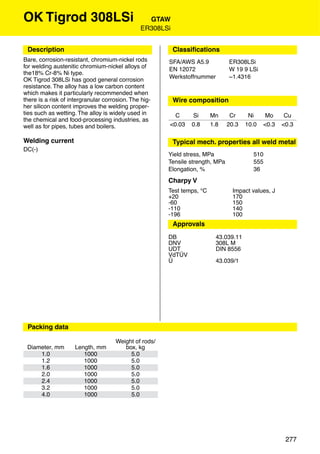

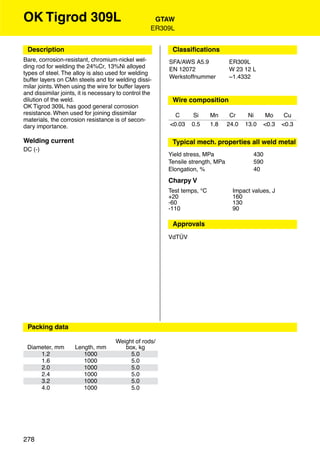

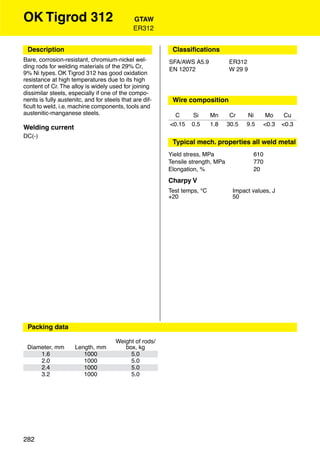

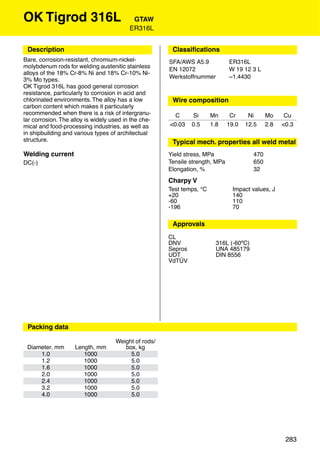

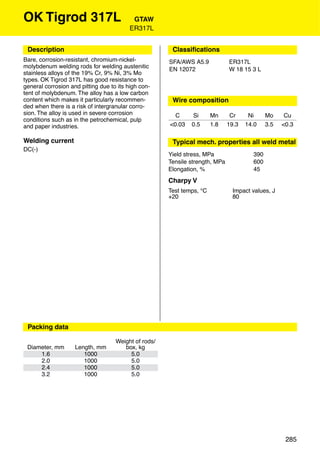

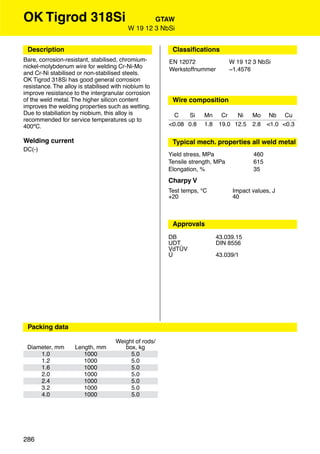

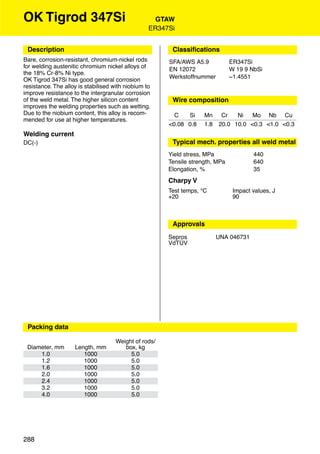

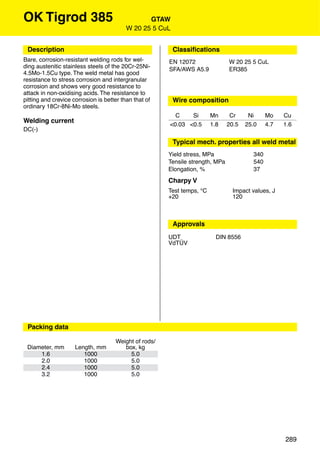

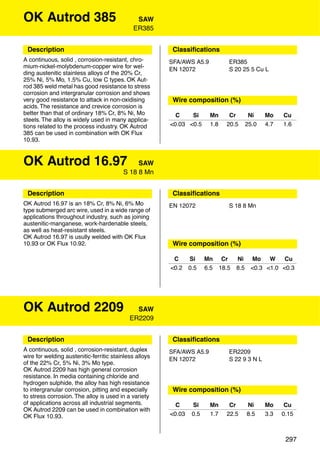

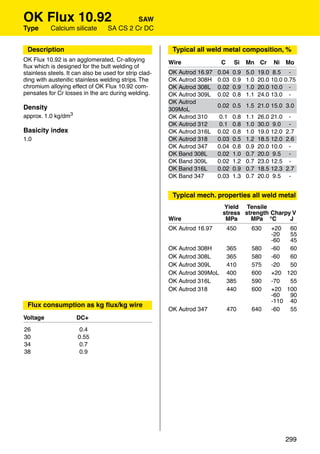

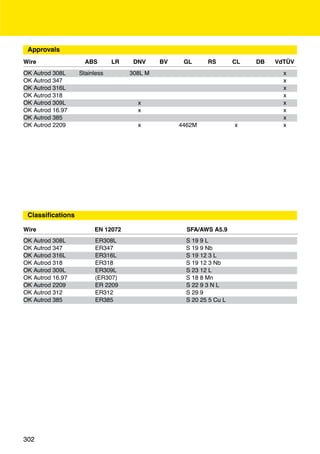

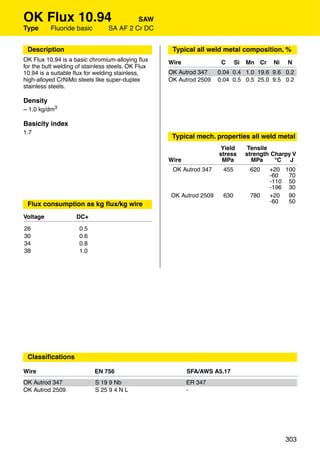

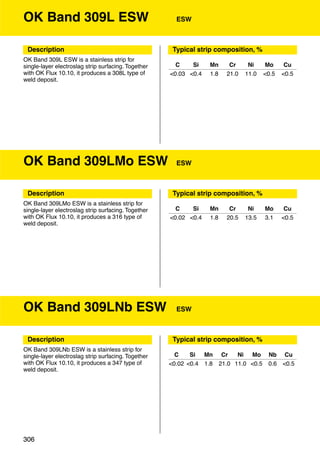

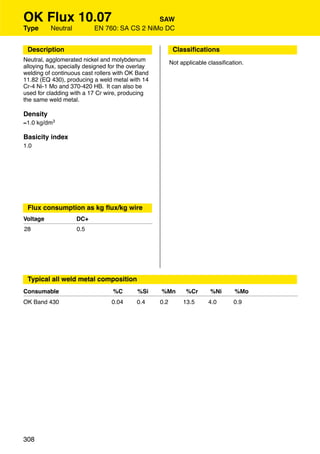

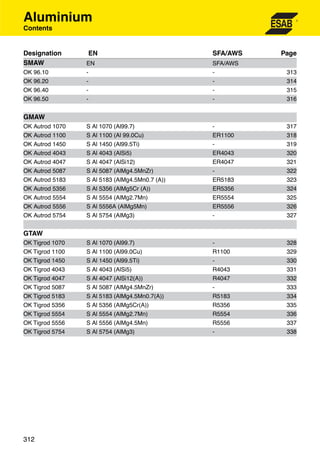

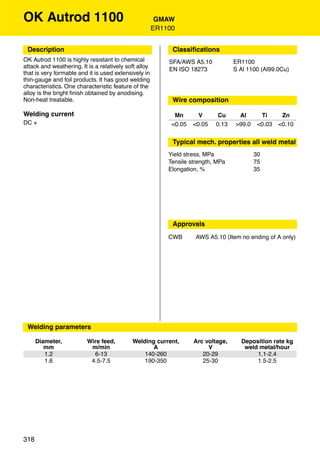

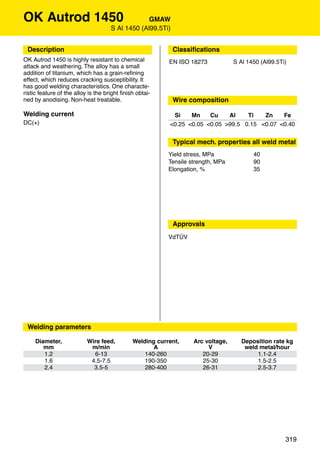

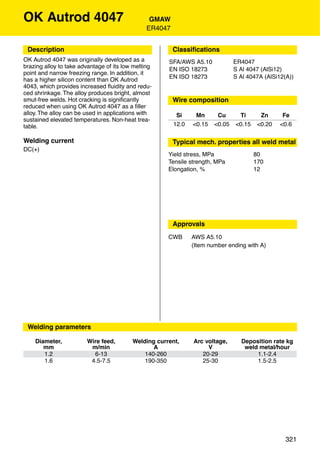

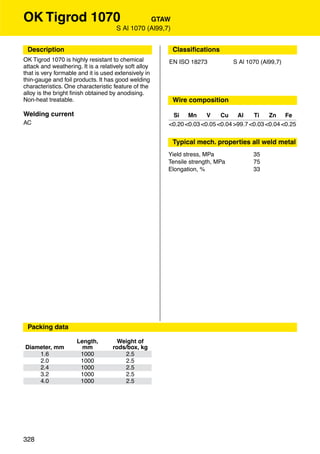

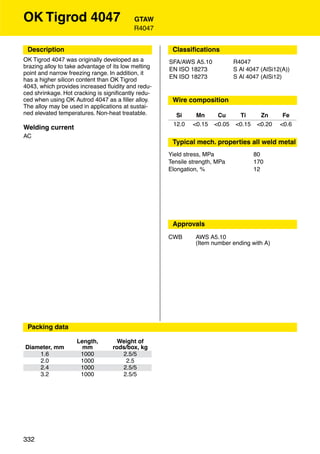

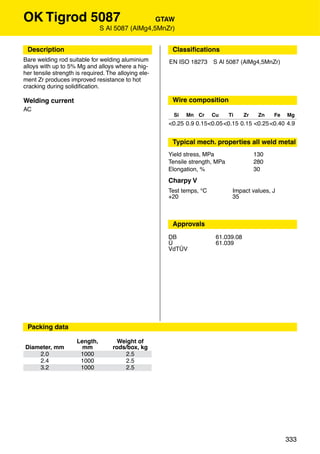

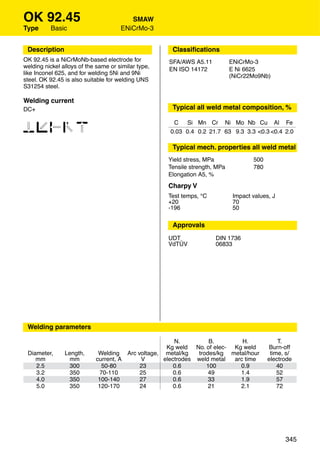

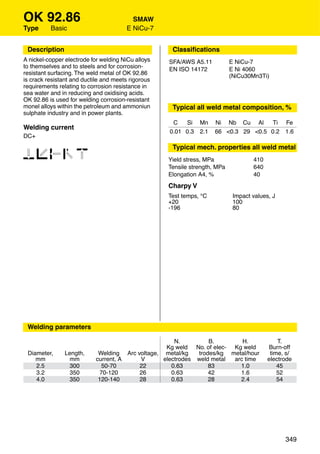

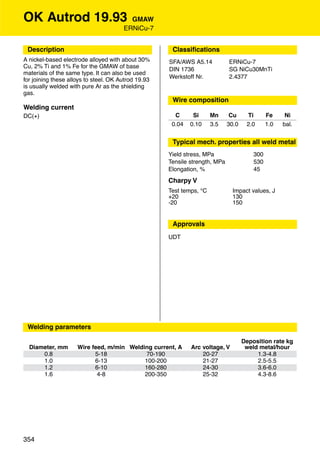

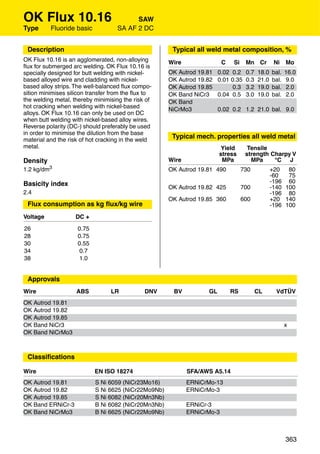

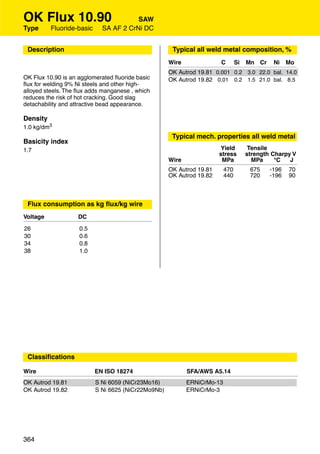

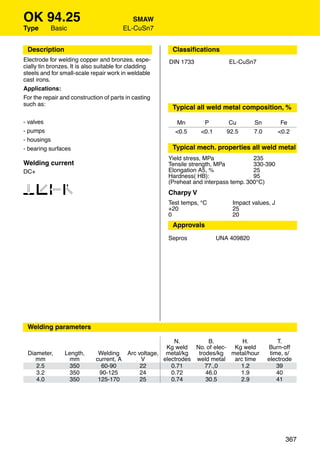

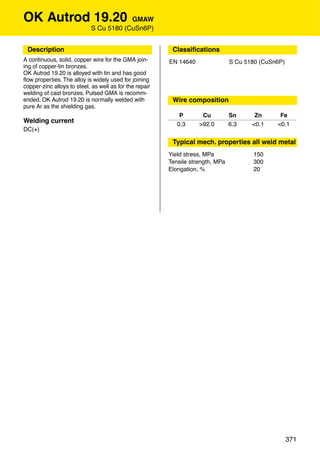

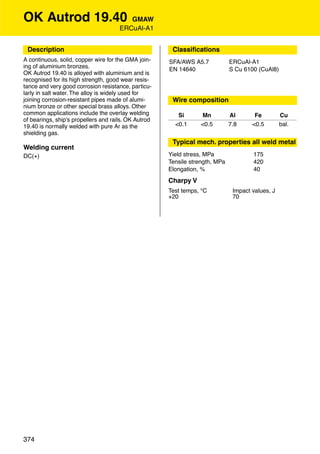

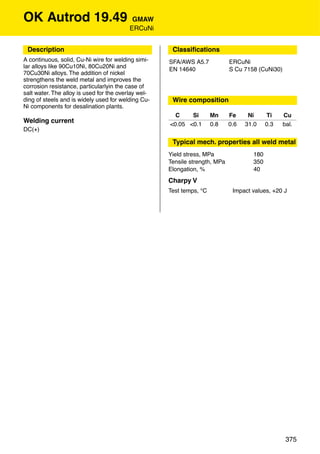

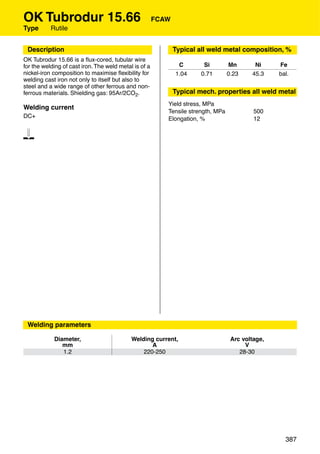

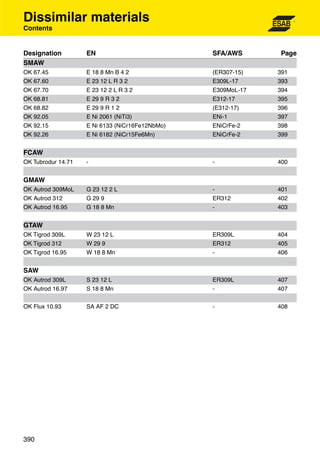

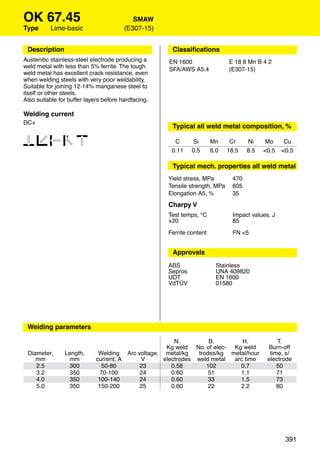

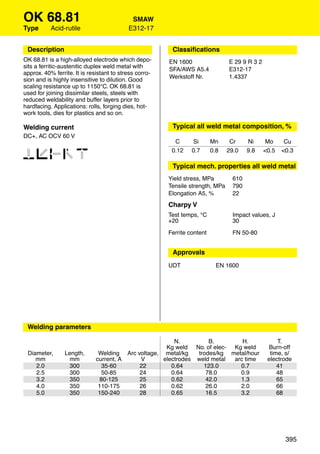

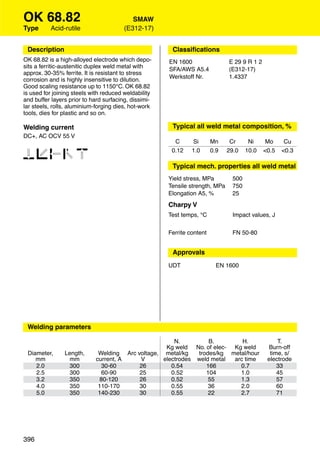

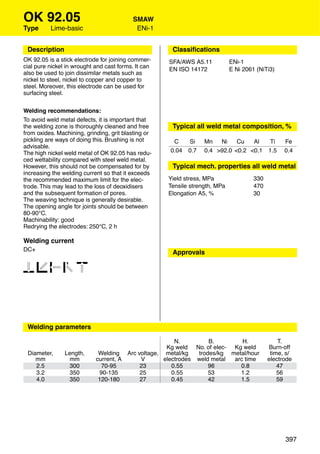

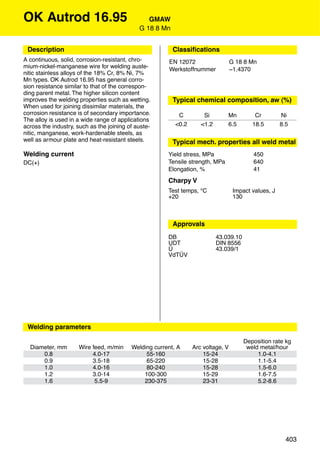

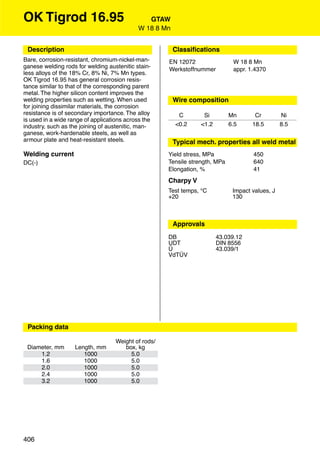

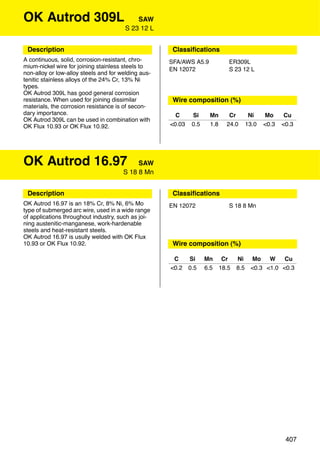

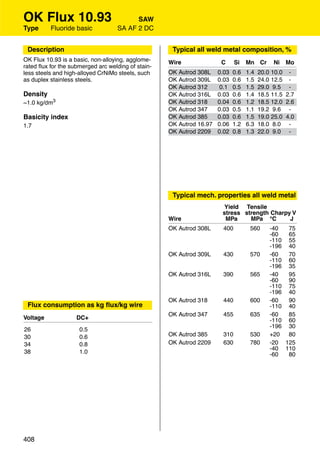

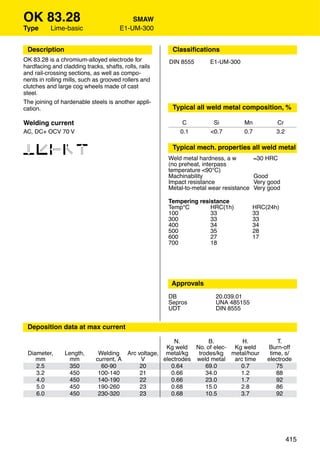

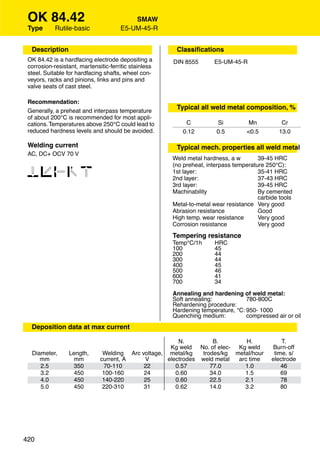

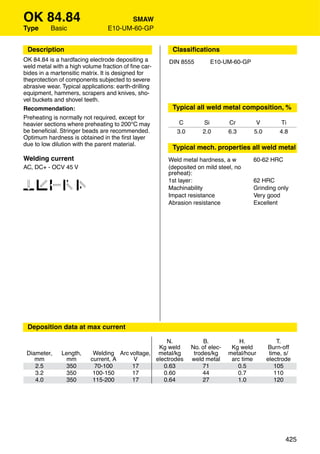

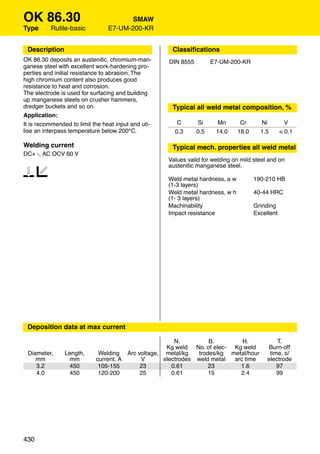

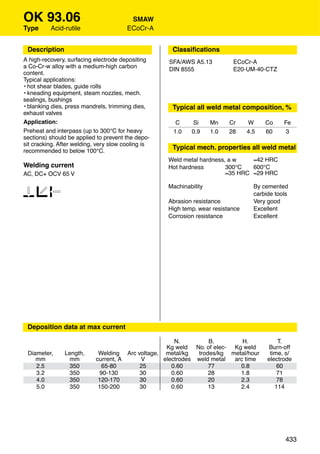

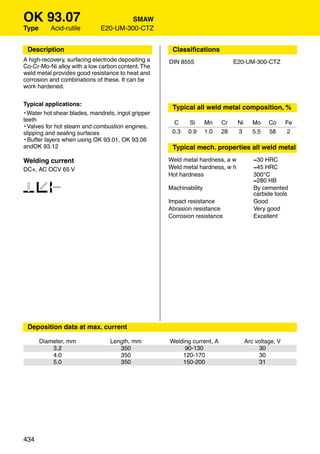

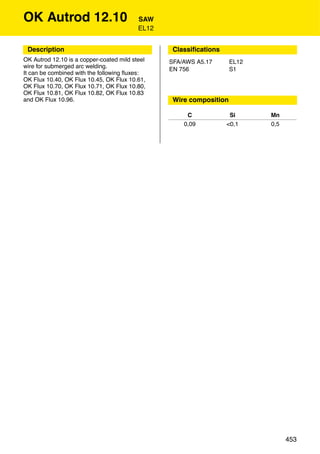

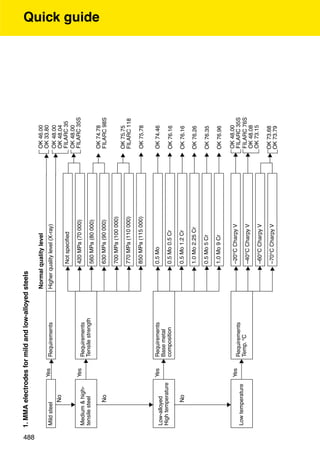

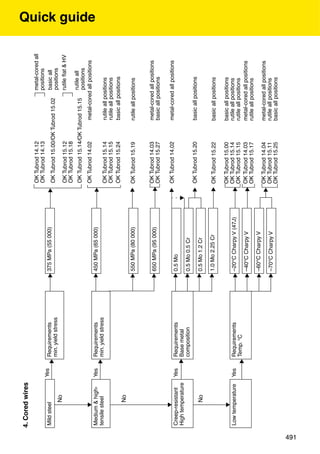

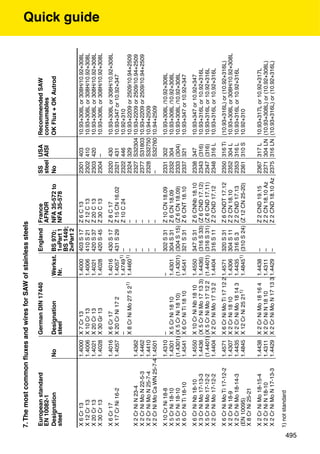

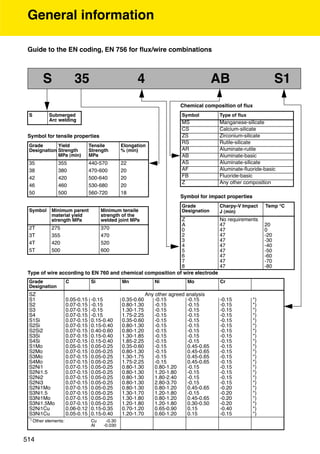

This document provides information on welding consumables for mild steels, including specifications and classifications for different types of electrodes. It lists various electrode designations according to standards like EN, SFA/AWS, and others. For each electrode, it provides descriptions of the welding characteristics and typical compositions. It also includes information on mechanical properties, approvals, welding parameters, and other technical details. The document contains data on consumables for processes like shielded metal arc welding (SMAW), flux-cored arc welding (FCAW), gas metal arc welding (GMAW), gas tungsten arc welding (GTAW), and submerged arc welding (SAW).