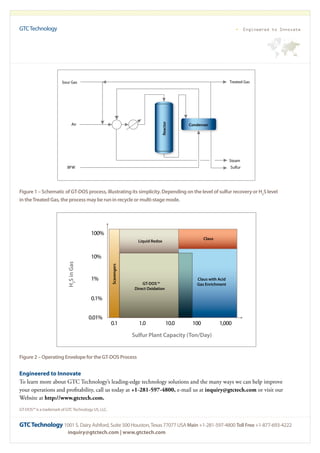

The GT-DOS process is a patented technology that uses a catalyst to directly convert hydrogen sulfide (H2S) in gas streams into elemental sulfur. It offers a simple and cost-effective solution for removing H2S and recovering sulfur from gas streams containing between 0.1 and 200 tons per day of sulfur. The process mixes the H2S-containing feed gas with air over an advanced metal oxide catalyst at 400°F to catalyze the reaction of H2S with oxygen to produce sulfur and water. The sulfur vapor is then condensed to recover molten sulfur.