The document outlines the application and inspection process for obtaining or varying a wholesale dealer's license with the MHRA, emphasizing compliance with good distribution practices (GDP) and legislation. Inspections are conducted to assess compliance, with deficiencies categorized into critical, major, and other levels, leading to required corrective actions and written responses from the inspected sites. Additionally, a risk-based inspection program, implemented by MHRA, prioritizes inspections based on the risk level of licensed wholesalers to ensure public health is adequately protected.

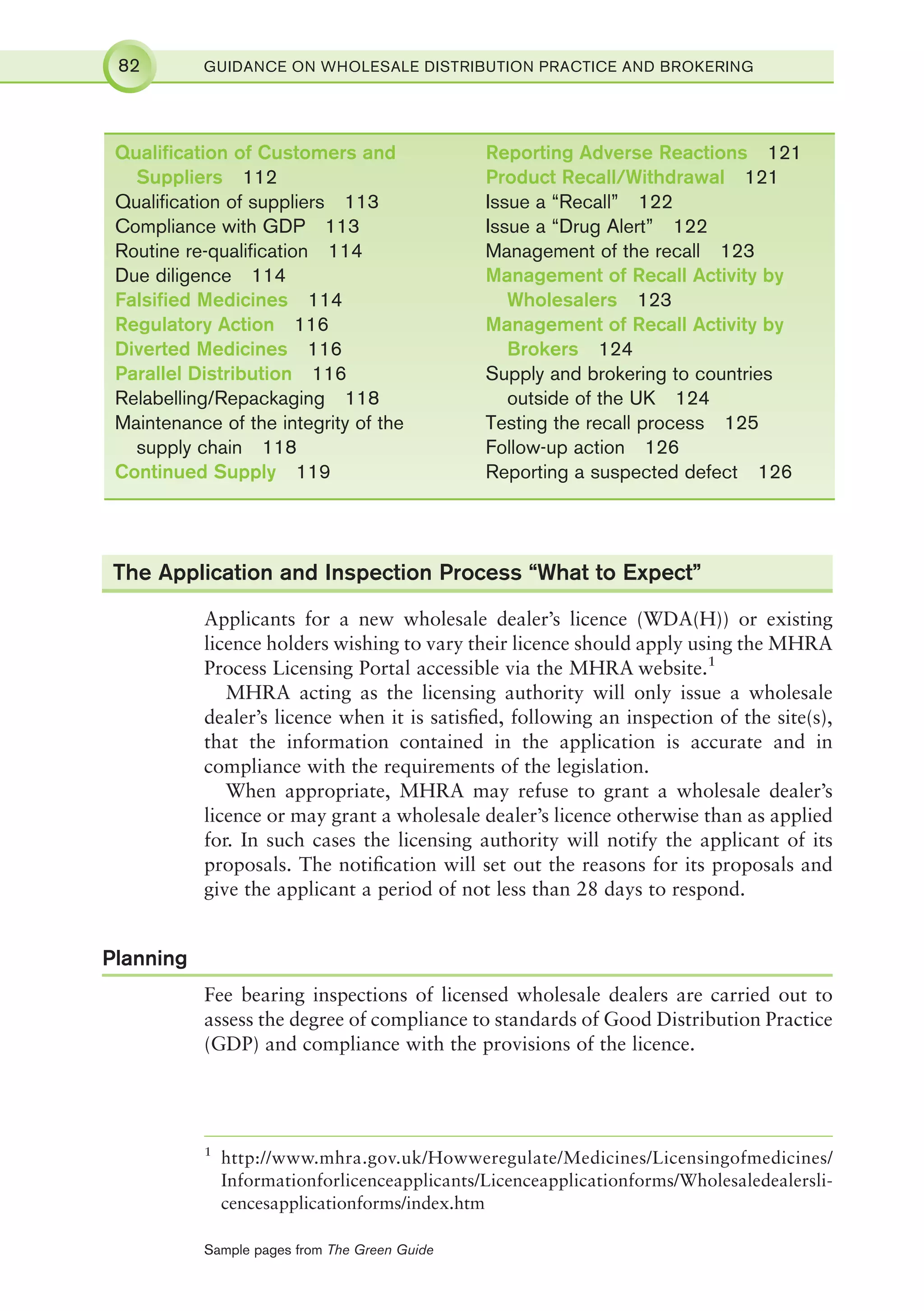

![frequency. As this process is not concluded until the inspection is closed the

risk ratings will not be discussed at the closing meetings. However a copy

of the full inspection report which includes the full risk rating rationale is

provided to sites once the inspection has been closed.

Issue of a certificate of GDP compliance and/or support of the site on the

relevant licence is indication of meeting the minimum level of GDP

compliance. Risk ratings identify the degree of surveillance required within

the licensing and inspection program. There is no intention that sites be

rated against each other as a result of risk ratings assigned by MHRA. Risk

ratings can change following inspection resulting in either increased or

decreased risk. Inspection risk ratings will not be published by MHRA.

There will be no formal process of appeal against risk ratings and future

inspection frequency. However any rating that results in an increased

inspection frequency from the previous standard will be peer reviewed

before conclusion by a GDP operations manager. MHRA does have a formal

complaints process if sites wish to log an issue, however any concerns

regarding the inspection process should be raised with the inspector.

Conditions of Holding a Wholesale Dealer’s Licence

The holder of a wholesale dealer’s licence must comply with certain

conditions in relation to the wholesale distribution of medicinal products.

These conditions are set out in regulations 43 – 45 of the Human Medicines

Regulations 2012 [SI 2012/1916] (“the Regulations”). They require that

the licence holder shall:

l comply with the guidelines on Good Distribution Practice (GDP);1

l ensure, within the limits of their responsibility as a distributor of medicinal

products, the appropriate and continued supply of such medicinal

products to pharmacies and persons who may lawfully sell such products

by retail or who may lawfully supply them in circumstances corresponding

to retail sale, so that the needs of patients in the UK are met;

l provide and maintain such staff, premises, equipment and facilities for

the handling, storage and distribution of the medicinal products under

the licence as are necessary to maintain the quality of, and ensure proper

distribution of the medicinal products;

l inform the licensing authority of any proposed structural alteration to, or

discontinued use of, premises to which the licence relates or premises

which have been approved by the licensing authority;

l inform the licensing authority of any change to the Responsible Person;

1

Guidelines on Good Distribution Practice of Medicinal Products for Human Use

(2013/C 343/01) http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:

C:2013:343:0001:0014:EN:PDF.

88 GUIDANCE ON WHOLESALE DISTRIBUTION PRACTICE AND BROKERING

Sample pages from The Green Guide](https://image.slidesharecdn.com/greenguide2015sample-150301114745-conversion-gate02/85/Rules-and-Guidance-for-Pharmaceutical-Manufacturers-Distributors-2015-The-Green-Guide-7-320.jpg)