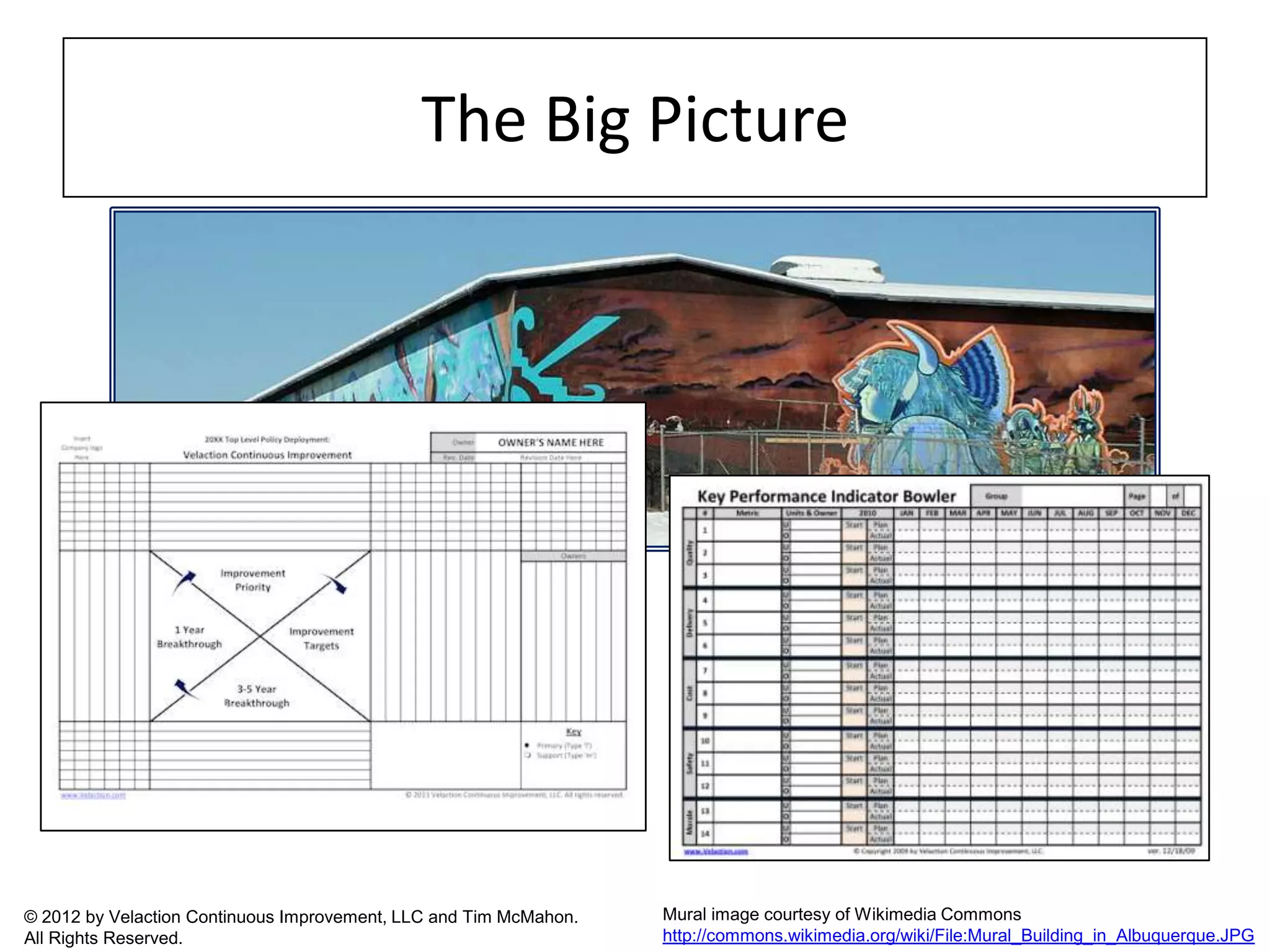

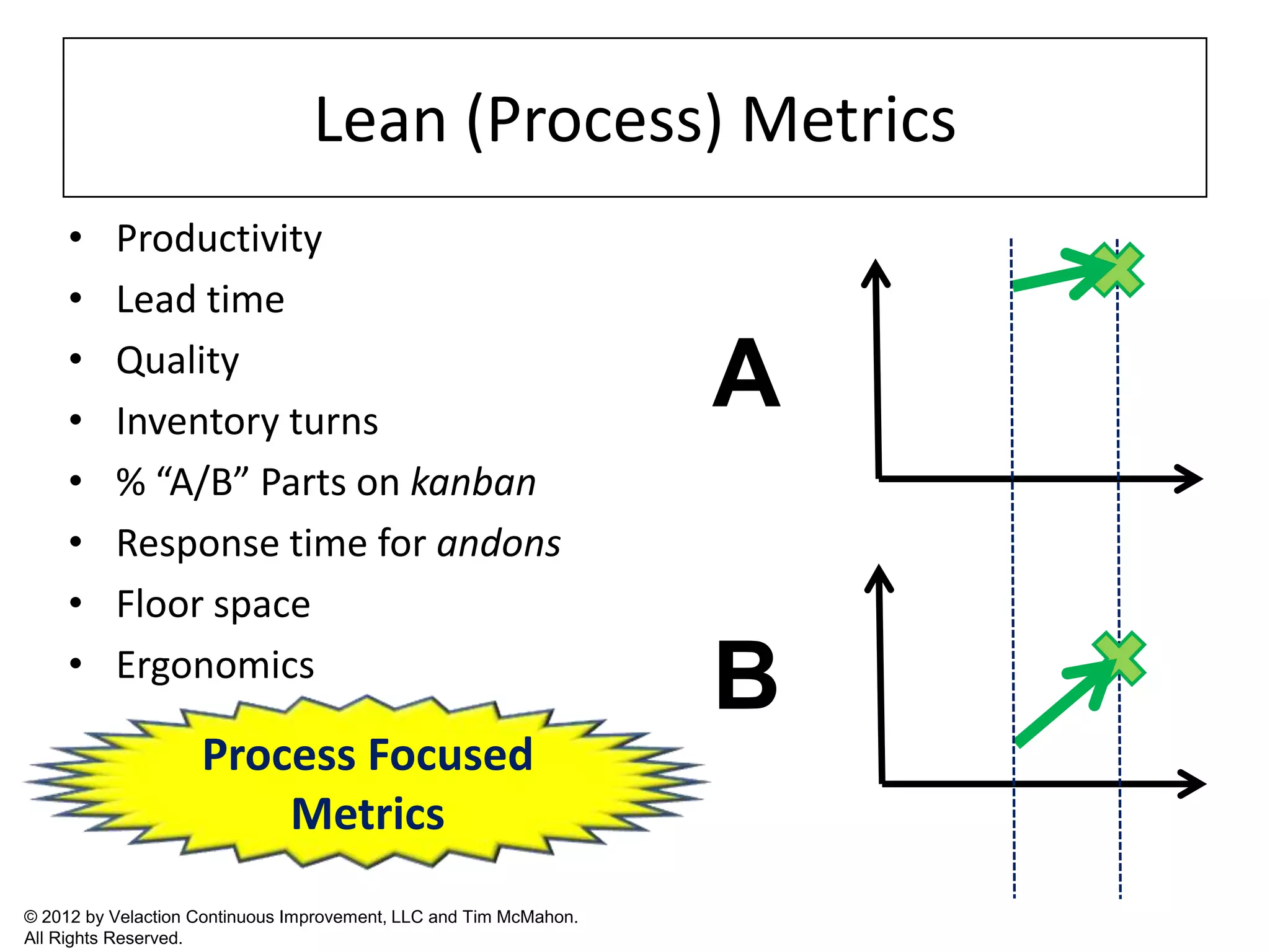

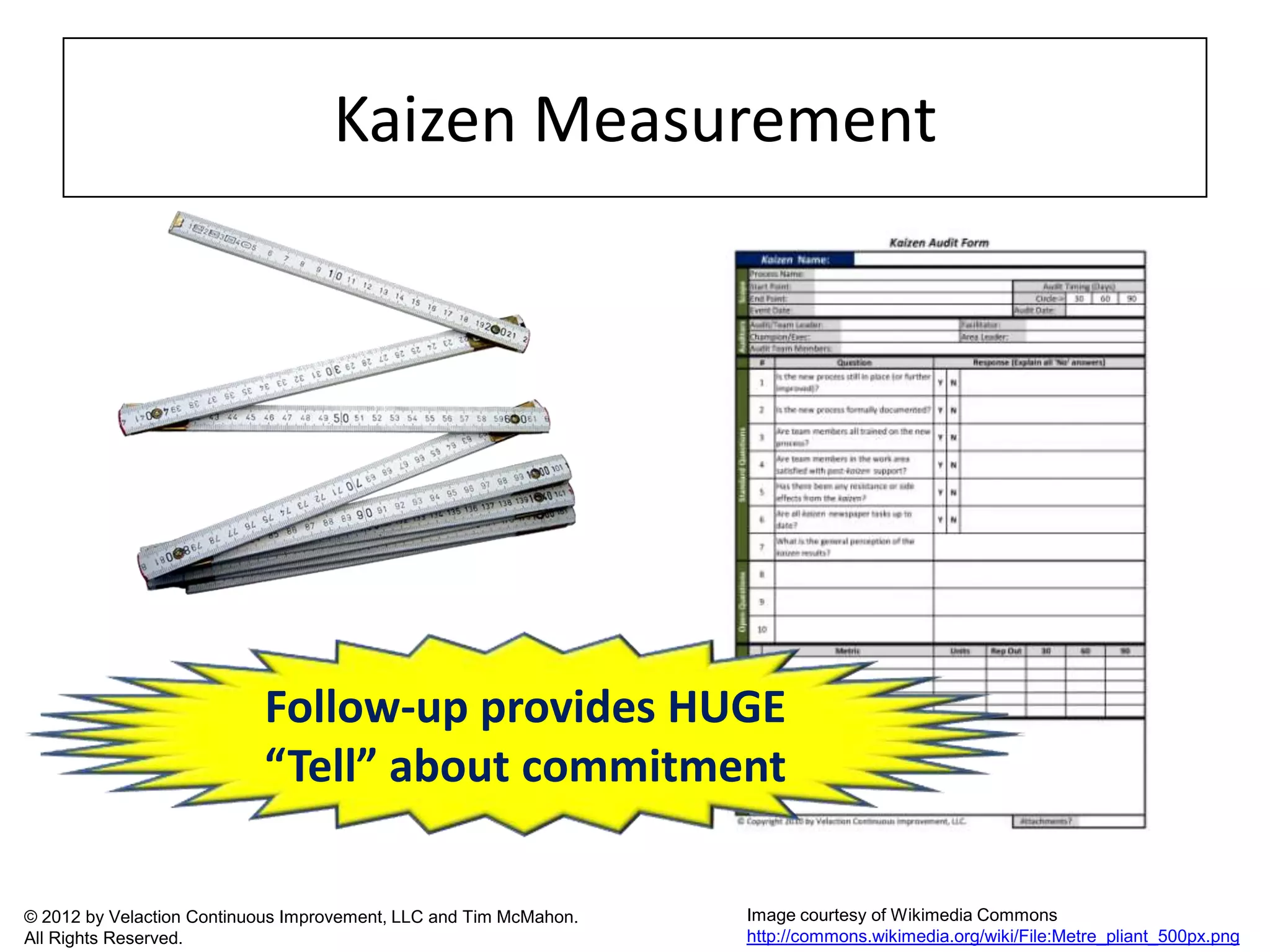

The document discusses evaluating progress on a lean journey, emphasizing key metrics such as productivity, lead time, and quality. It highlights the importance of leadership involvement, training participation, and a strong organizational culture in achieving lean initiatives. Additionally, it notes the necessity for regular assessments and the importance of having a clear strategy and the right tools to support effective lean practices.