- Adam Goodin is a senior civil engineering student at the University of Kentucky interning for his third rotation at Duke Energy's Gibson Station.

- During this rotation, he is providing document control and engineering support for various projects including a unit refurbishment, mercury re-emission project, and the planning and design of a dry bottom ash conversion system.

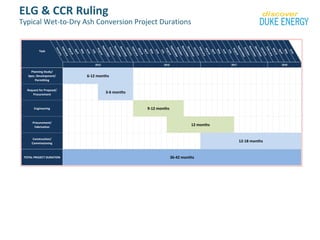

- One of his main responsibilities is supporting the engineering efforts for the dry bottom ash conversion project which is being undertaken to comply with new EPA regulations and will involve designing and installing a continuous dewatering and recirculation system over the next 3-4 years.