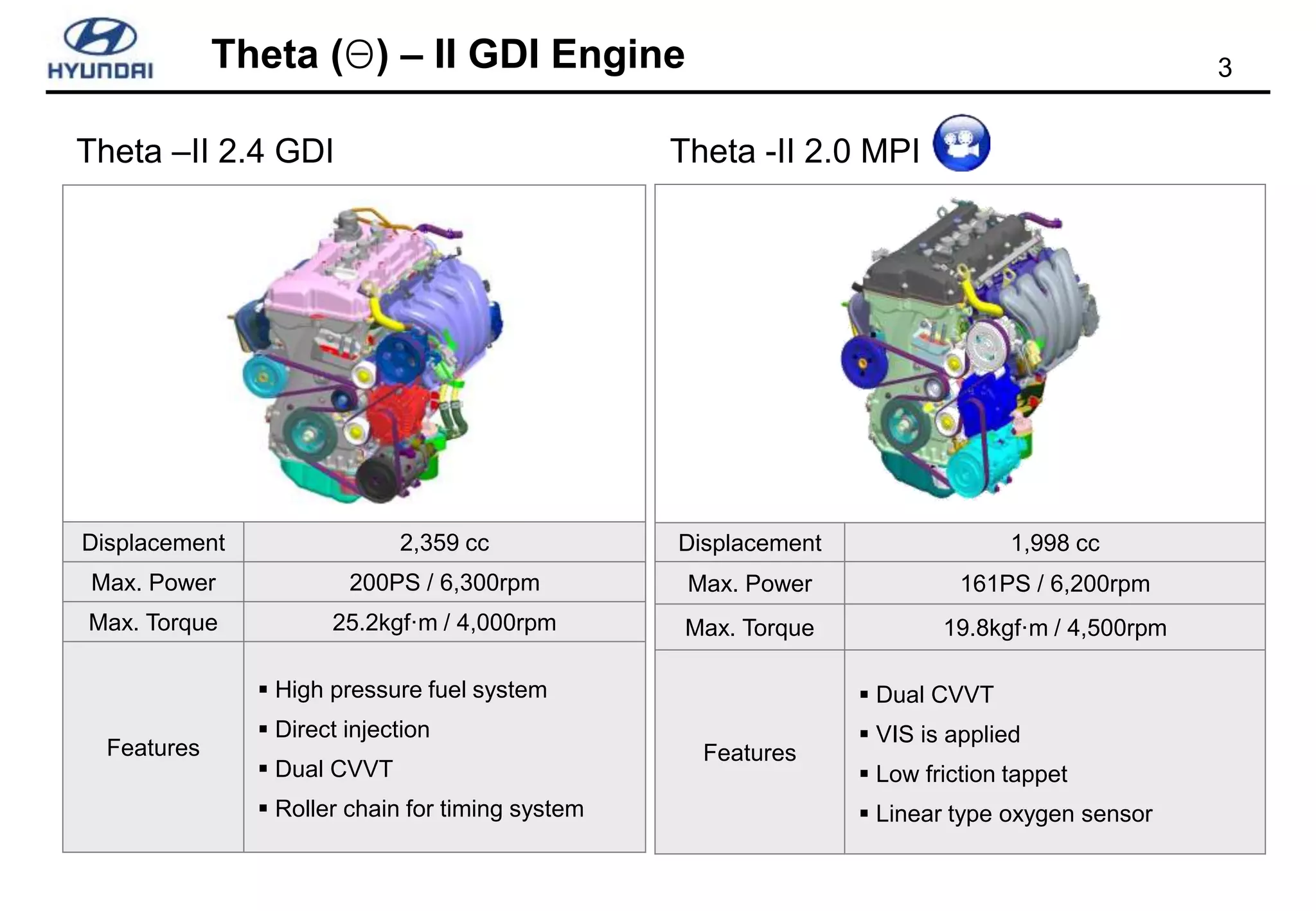

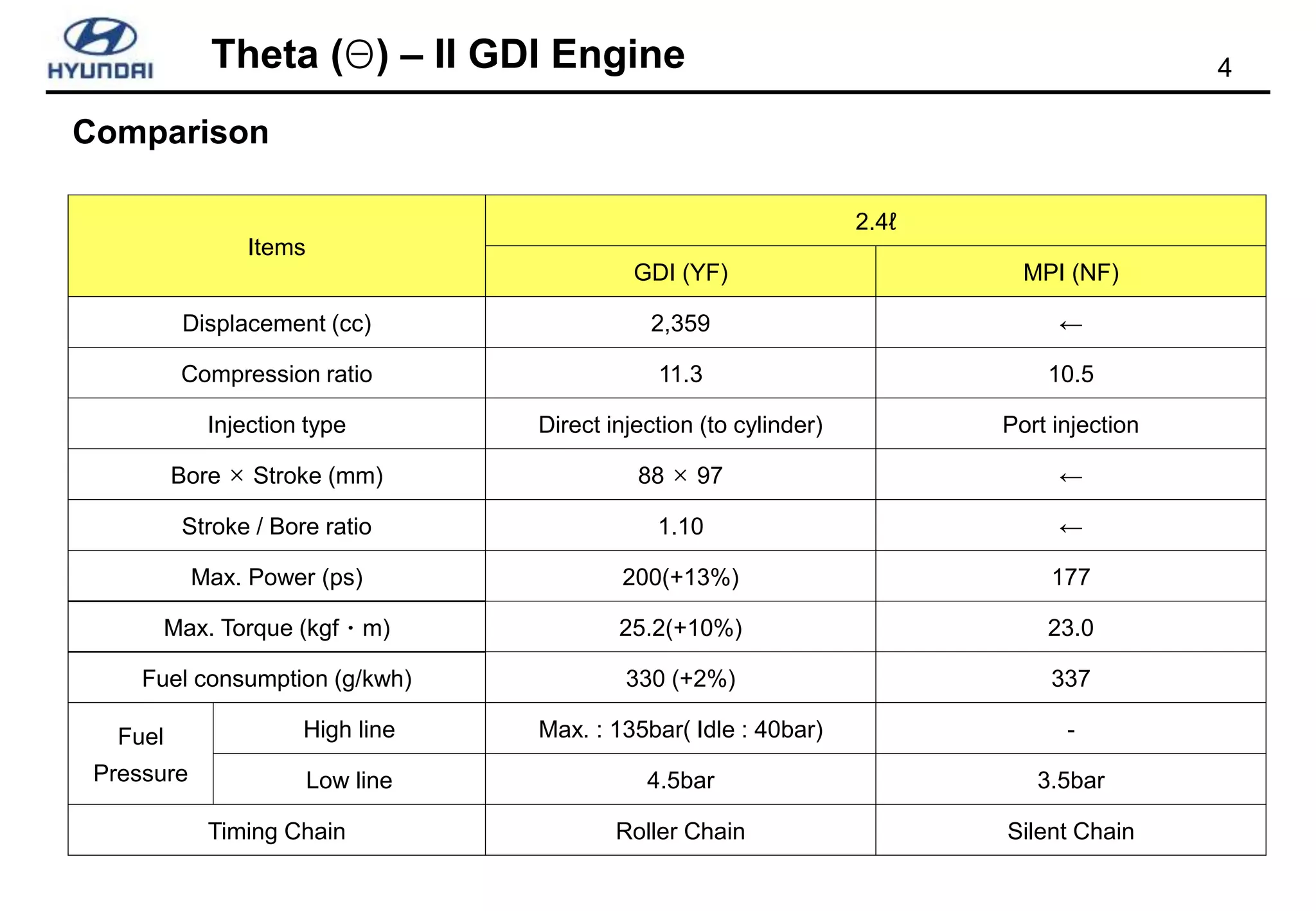

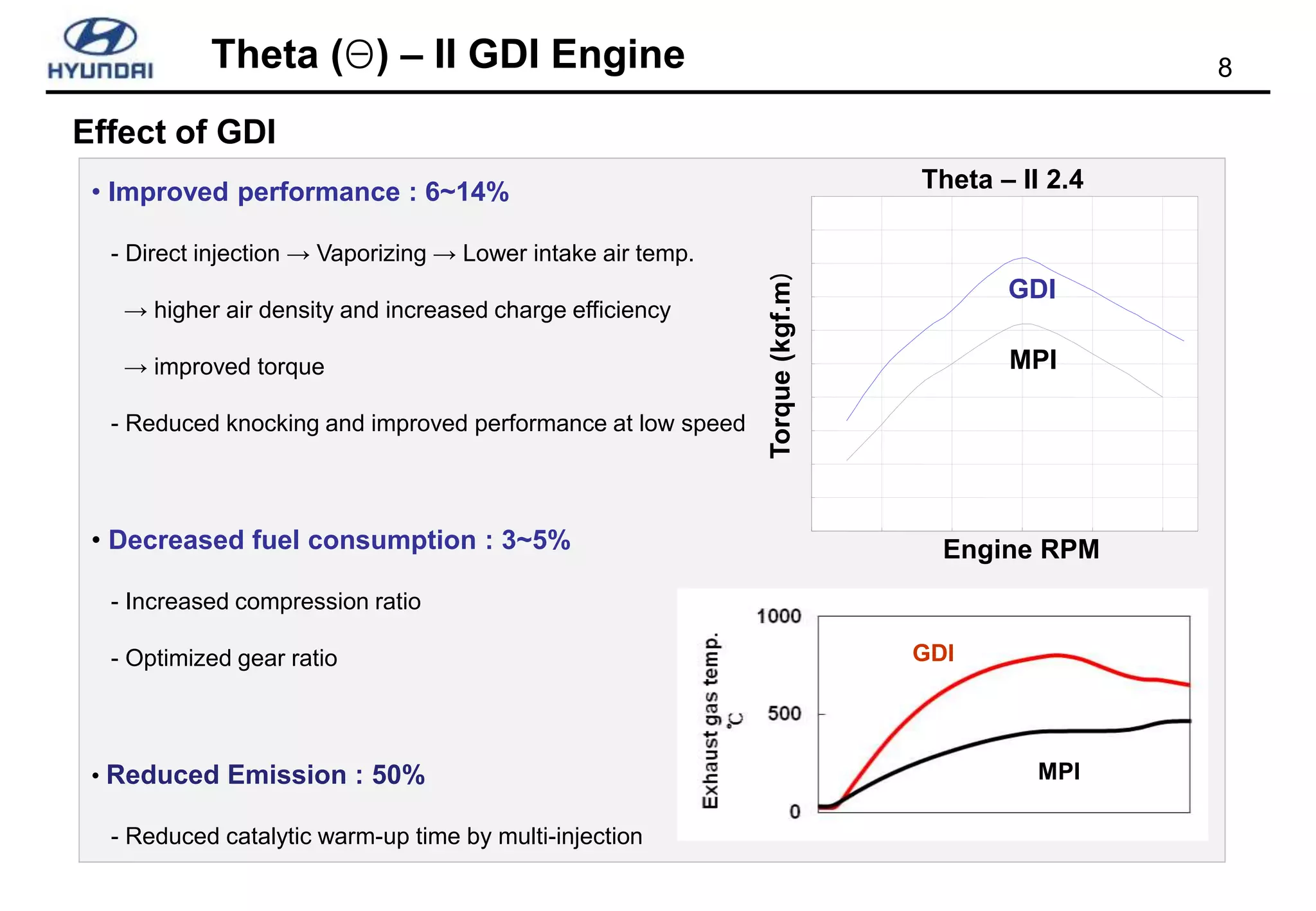

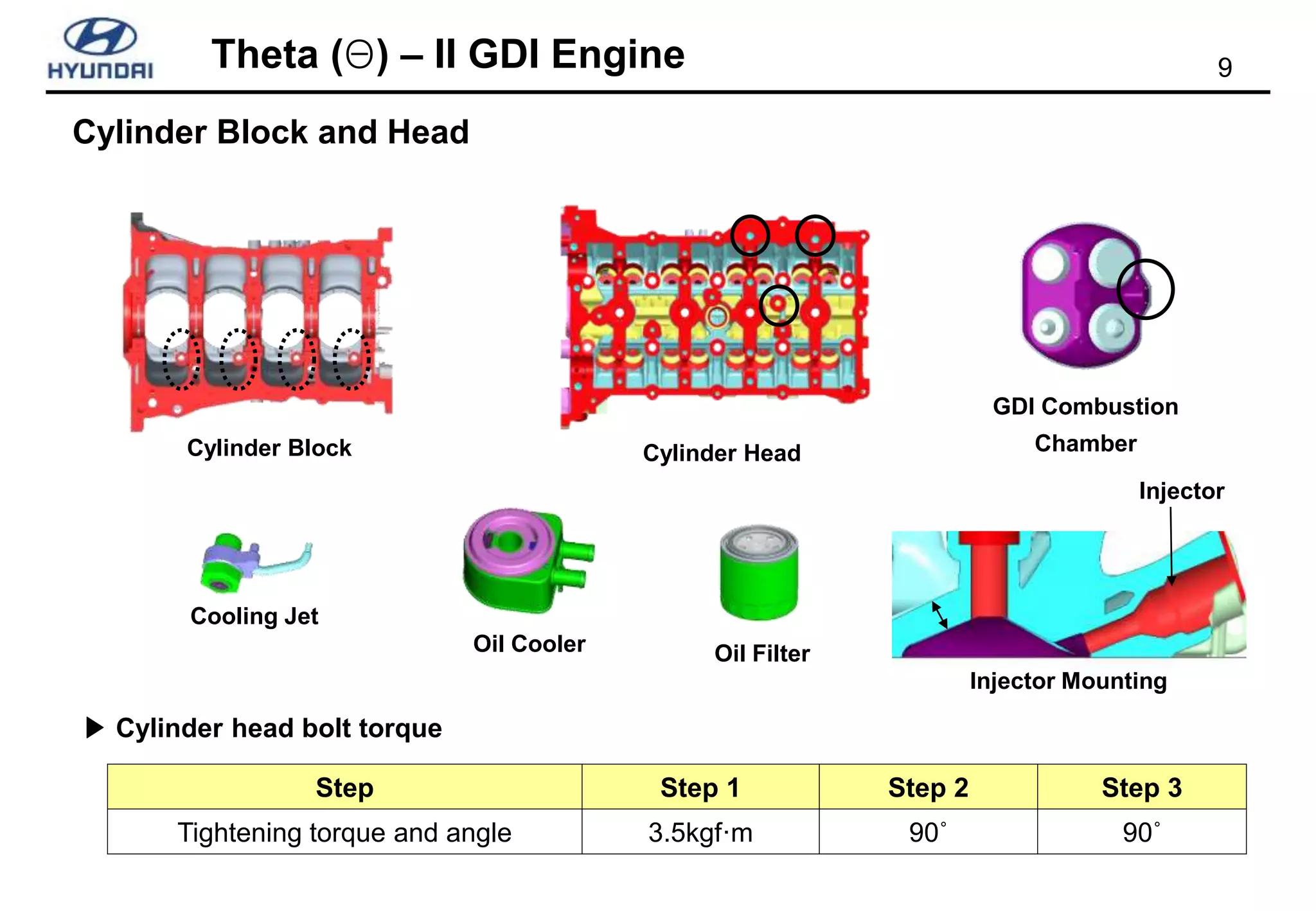

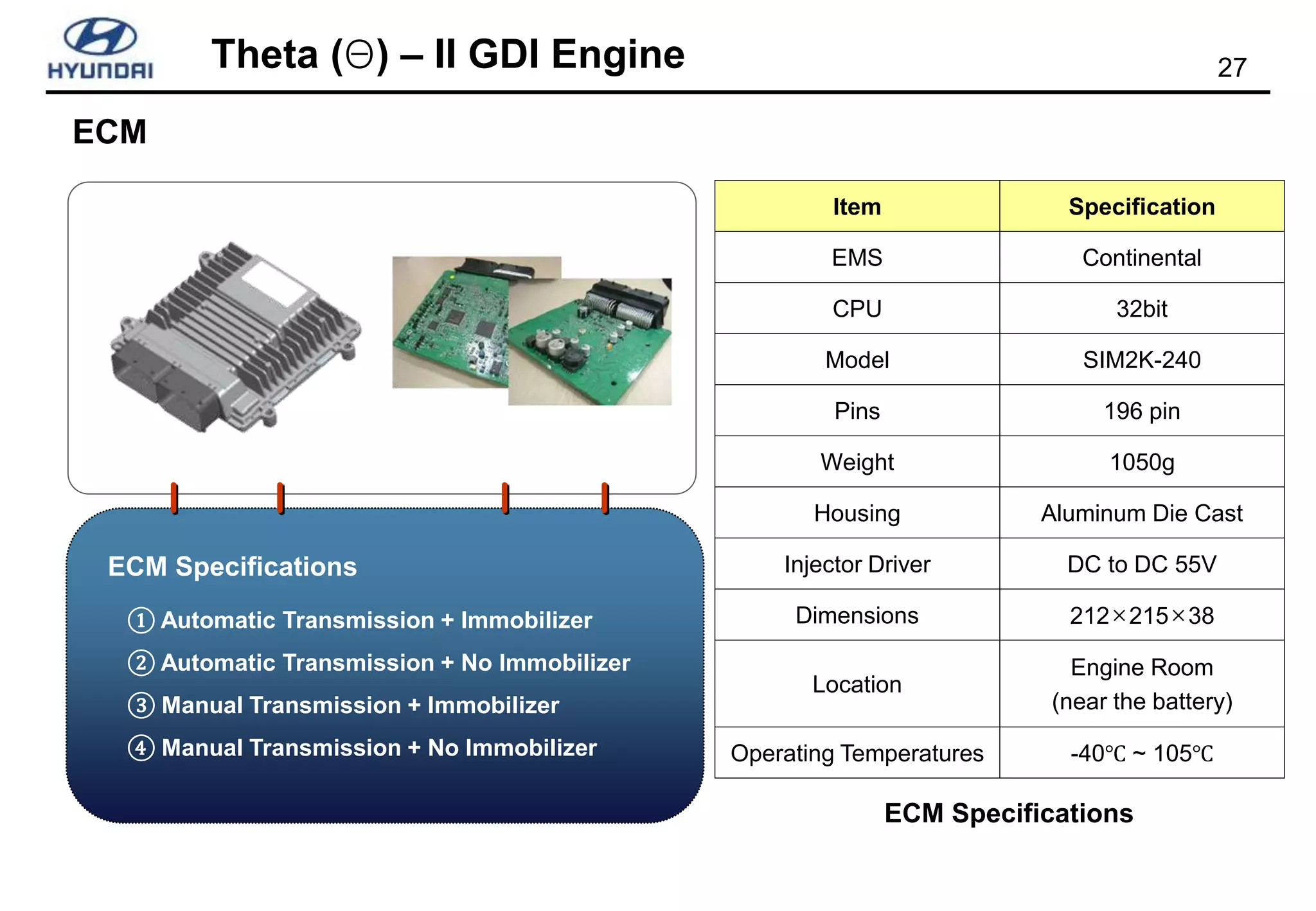

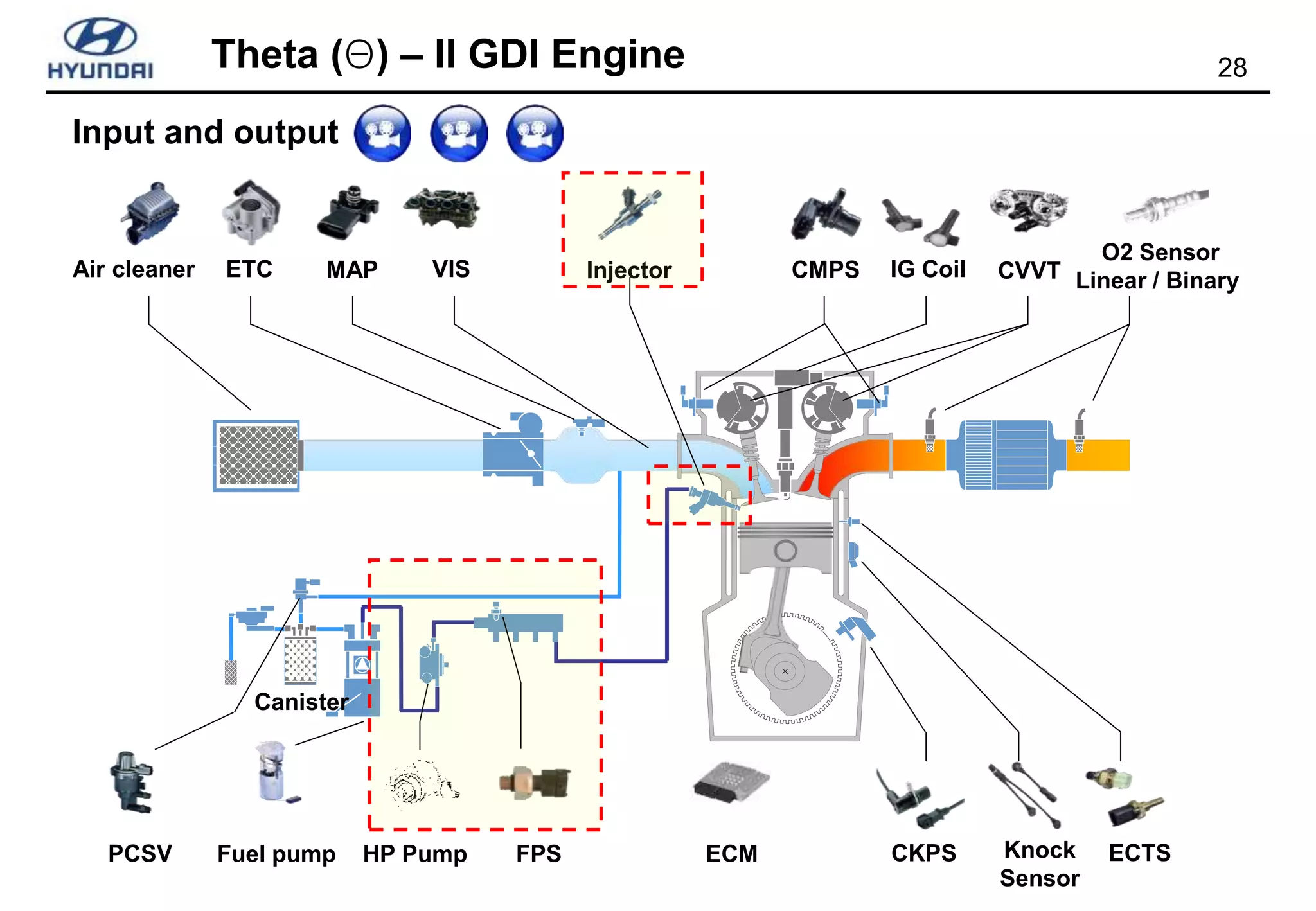

The document summarizes Hyundai's Theta (Θ) - II GDI engine. It describes the key specifications and improvements over the previous MPI engine, including increased power output, torque, and fuel efficiency while decreasing emissions. The main technologies enabling this are direct injection, higher compression ratio, dual CVVT, and multi-injection. The document also provides details on the high pressure fuel system components, such as the high pressure pump, fuel rail, injectors, and pressure sensor.

![10

Theta (Θ) – II GDI Engine

[ Camshaft]

Slotted

High pressure pump

driving lobe

• Slotted cam love for reducing weight

• Added cam lobe for high pressure pump

• Fuel pressure is made by camshaft

Camshaft and HP Pump Bracket

HP Pump Bracket Cylinder Head Cover

• Added bracket and hole on cylinder head cover for HP pump](https://image.slidesharecdn.com/321-yfgdiengine20090826-230216040023-48f6c061/75/Hyundai-Theta-II-GDI-Engine-ppt-10-2048.jpg)

![17

Theta (Θ) – II GDI Engine

GDI Fuel System – HP Pump & Fuel Pressure Regulator Valve

[ 고압펌프 로브

조립상태 ]

Chamber

Delivery

Chamber

Rail Rail

Fuel Input Fuel Return

Fuel Pressurization

and Discharge Fuel Discharge

Intake Supply

Chamber

Chamber

High-Pressure Pump Mechanism

Voltage

Current](https://image.slidesharecdn.com/321-yfgdiengine20090826-230216040023-48f6c061/75/Hyundai-Theta-II-GDI-Engine-ppt-17-2048.jpg)

![30

Theta (Θ) – II GDI Engine

Evaporation control

Filter

Canister

Throttle

Valve

Cylinder

CCV

PCSV

FTPS

Fuel Tank

P L

Fuel Level Sensor

[ PCSV ]

CCV

PCSV

FTPS](https://image.slidesharecdn.com/321-yfgdiengine20090826-230216040023-48f6c061/75/Hyundai-Theta-II-GDI-Engine-ppt-30-2048.jpg)