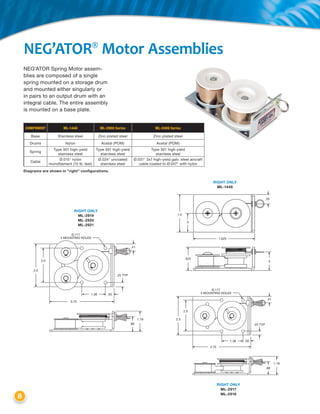

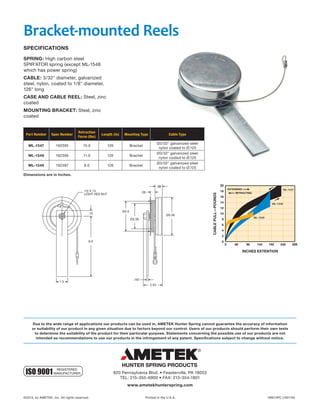

This document provides information on constant force extension springs produced by Hunter Spring. It includes a table listing over 50 part numbers for NEG'ATOR constant force extension springs with specifications such as load rating, drum diameter, deflection range, material thickness and width. It also describes the features and operating principles of NEG'ATOR constant force extension springs, which produce a nearly constant force output over their deflection range due to their coiled, prestressed design.