The article presents a fuzzy controller for the plant-wide control of biological wastewater treatment processes, focusing on the reduction of greenhouse gas emissions, particularly nitrous oxide and carbon dioxide. Using a benchmark simulation model, the developed controller integrates 14 inputs and 6 outputs to improve effluent quality and operational costs while addressing greenhouse gas emissions. Results demonstrate that the fuzzy controller effectively reduces emissions while maintaining satisfactory treatment outcomes.

![ISA Transactions 77 (2018) 146–166

Practice article

Fuzzy logic for plant-wide control of biological wastewater treatment

process including greenhouse gas emissions

I. Santín a,b,*

, M. Barbu a,c

, C. Pedret a

, R. Vilanova a

a

Department of Telecommunications and Systems Engineering, School of Engineering, Universitat Autònoma de Barcelona, 08193, Bellaterra, Barcelona, Spain

b

Escola Universitria Salesiana de Sarrià, Passeig Sant Joan Bosco 74, 08017 Barcelona, Spain

c Department of Automatic Control and Electrical Engineering, “Dunarea de Jos” University of Galati, 800008 Galati, Romania

a r t i c l e i n f o a b s t r a c t

Article history:

Received 20 November 2017

Revised 9 April 2018

Accepted 13 April 2018

Available online 25 April 2018

Keywords:

Fuzzy control

Wastewater treatment plants

GHGemissions

Benchmark simulation model no 2 gas

The application of control strategies is increasingly used in wastewater treatment plants with the aim of

improving effl uent quality and reducing operating costs. Due to concerns about the progressive growth of

greenhouse gas emissions (GHG), these are also currently being evaluated in wastewater treatment plants.

The present article proposes a fuzzy controller for plant-wide control of the biological wastewater treatment

process. Its design is based on 14 inputs and 6 outputs in order to reduce GHG emissions, nutrient concentra-

tion in the effl uent and operational costs. The article explains and shows the effect of each one of the inputs

and outputs of the fuzzy controller, as well as the relationship between them. Benchmark Simulation Model

no 2 Gas is used for testing the proposed control strategy. The results of simulation results show that the

fuzzy controller is able to reduce GHG emissions while improving, at the same time, the common criteria of

effl uent quality and operation al costs.

© 2018 ISA. Published by Elsevier Ltd. All rights reserved.

1. Introduction

Wastewater treatment plants (WWTPs) are used worldwide to

ensure the suitable water quality for the receiving environment.

Some of the pollutants are reduced to allowed levels by the default

WWTP structure without applying any automatic control. However,

other pollutants are more diffi cult to be reduced. For this reason and

also to restrict operational costs, the application of control engineer-

ing in WWTPs is playing an important role in research in recent years

(Vilanova et al. [1,2]).

Another major issue regarding to WWTPs is the greenhouse gas

(GHG) emissions generated during the treatment process. Actually,

GHG emissions are important in maintaining the proper tempera-

ture for life on Earth, since they retain part of the infrared radiations

reflected from the surface of the Earth. The problem is that the GHG

emissions increase generated by the industrialized world is creating

a global climate change, which can cause serious impacts on both the

land and socioeconomic systems.

* Corresponding author. Department of Telecommunications and Systems Engi-

neering, School of Engineering, Universitat Autònoma de Barcelona, 08193, Bellaterra,

Barcelona, Spain.

E-mail addresses: Ignacio.Santin@uab.cat (I. Santín), Marian.Barbu@ugal.ro (M.

Barbu), Carles.Pedret@uab.cat (C. Pedret), Ramon.Vilanova@uab.cat (R. Vilanova).

Among the GHG emitted in the wastewater treatment process,

the present paper focus on the nitrous oxide (N2O) emissions dur-

ing the nitrification process, on the carbon dioxide (CO2) emissions

due to endogenous respiration of biomass, on CO2 generated from

external carbon source production and on CO2 due to electric con-

sumption.

There are previous works in the literature as Kimochi et al. [3],

Kampschreur et al. [4], Foley et al. [5], Law et al. [6], Flores-Alsina

et al. [7,8], Aboobakar et al. [9] or Wang et al. [10], which show that

N2O is an intermediate in the nitrification of WWTPs and that it has a

high impact in the GHG emissions. Incomplete nitrification or deni-

trification can lead to an accumulation of nitrite concentration (SNO2

)

that triggers the production of N2O emissions. The endogenous res-

piration of the biomass is a process of autoxidation that takes place

after the depletion of food reserves. In this process, the microorgan-

isms metabolize their own cellular material until its own destruction

generating CO2 emissions, as explained in Monteith et al. [11]. In the

case of the electric consumption, it is related to the fact that the elec-

tricity is mostly generated by burning fossil fuels, which generates

CO2 emissions.

In this article, the control strategies applied to cope with effl uent

quality, costs and GHG emissions have been tested using the Bench-

mark Simulation Model no 2 Gas (BSM2G), which was introduced

by Flores-Alsina et al. [7]. This benchmark has been modified over

the last years by the same authors, who added ammonia oxidizing

https://doi.org/10.1016/j.isatra.2018.04.006

0019-0578/© 2018 ISA. Published by Elsevier Ltd. All rights reserved.

Contents lists available at ScienceDirect

ISA Transactions

journal homep ag e: www. elsevi er. com/locat e/isat rans](https://image.slidesharecdn.com/fuzzy-logic-for-plant-wide-control-of-biological-wastewater-tr2018isa-tran-191011175840/75/Fuzzy-logic-for-plant-wide-control-of-biological-wastewater-treatment-process-including-greenhouse-gas-emissions-1-2048.jpg)

![I. Santín et al. / ISA Transactions 77 (2018)146–166 147

List of abbreviations

AE Aeration Energy (kWh/d)

AOB Ammonia Oxidizing Bacteria

ASM1 Activated Sludge Model no. 1

BOD5 5-day Biological Oxygen Demand (mg/l)

Qa Internal recycle flow rate (m3

/d)

qEC External carbon flow rate (m3

/d)

Qin Influent flow rate (m3

/d)

qEC,1 External carbon flow rate in the first tank (m3

/d)

Qw Wastage flow rate (m3

/d)

Qst Flow rate from the storage tank (m3

/d)

BSM1 Benchmark Simulation Model no 1 SNtot Total nitrogen concentration (mg/l)

BSM2 Benchmark Simulation Model no 2

BSM2G Benchmark Simulation Model no 2 Gas

CO2 Carbon dioxide (kg/d)

COD Chemical Oxygen Demand (mg/l)

CODt total Chemical Oxygen Demand (mg/l)

DCS Default COntrol Strategy

EC External Carbon (kg/d)

EQI Effl uent Quality Index (kg of pollutants/d)

GHG Greenhouse gases

HEnet Net Heating Energy (kWh/d)

SNtot,e

Total nitrogen concentration in the effl uent (mg/l)

SNH Ammonium and ammonia nitrogen concentration

(mg/l)

SNH,in Ammonium and ammonia nitrogen concentration at

the input of the primary clarifier (mg/l)

SNH,i Ammonium and ammonia nitrogen concentration in

tank i (mg/l)

SNH,e Ammonium and ammonia nitrogen concentration in

the effl uent (mg/l)

SNO Nitric Oxide concentration (mg/l)

HRT Hydraulic Retention Time (s)

KL a Oxygen transfer coeffi cient (d−1

)

KLai Oxygen transfer coeffi cient in tank i (d−1

)

ME Mixing Energy (kWh/d)

METprod Methane production in the anaerobic digester (kg/d)

N2O Nitrous oxide (kg equivalent CO2/d)

SNO2

SNO3

SNO3 i

SNKj

SN2O

Nitrite concentration (mg/l)

Nitrate concentration (mg/l)

Nitrate concentration in tank i (mg/l)

Kjeldahl nitrogen (mg/l)

Dissolved nitrous oxide concentration (mg/l)

SO Dissolved oxygen concentration (mg/l)

N2 dinitrogen CO2/d)

OCI Overall Cost Index

SO,i Dissolved oxygen concentration in tank i (mg/l)

SP Sludge Production (kg/d)

PE Pumping Energy (kWh/d)

PI Proportional-Integral

Tas Temperature (◦C)

Q Flow rate (m3

/d)

TSS Total Suspended Solids (mg/l)

WWTP Wastewater Treatment Plants

bacteria (AOB) denitrification pathway for N2O emissions based on

Guo and Vanrolleghem [12]. In addition, BSM2G is the result of the

evolution of previous benchmarks. First, the Benchmark Simulation

Model no 1 (BSM1) was developed in Copp [13], which includes

the biological treatment and a secondary clarifier, using one-week

period to evaluate results. Next, the Benchmark Simulation Model no

2 (BSM2) (Gernaey et al. [14]) included the whole cycle of a WWTP,

adding the sludge treatment and a primary clarifier, applying a more

complete influent with a one-year period for evaluation. BSM2G dif-

fers from BSM2 mainly in the inclusion of GHG emissions assess-

ment. It should be noted that the use of models for the evaluation of

GHG emissions is currently restricted to the research domain, due to

the incomplete knowledge regarding the SNO2

production pathways

(Mannina et al. [15], Ni and Yuan [16]).

Although the present work uses Proportional-Integral (PI) con-

trollers, the main contribution is based on a fuzzy controller to cope

with the mentioned problems in WWTPs. There are already many

works in the literature that have applied fuzzy control strategies

in WWTPs. For example, the fuzzy controller was applied for the

basic control loop of the dissolved oxygen concentration (SO) in the

fifth reactor (SO,5) by using BSM1 in Belchior et al. [17] and Nasr

et al. [18] or in a pilot plant in Traore et al. [19]. In the case of

Santín et al. [20] and Meyer and Pöpel [21], the fuzzy controller is

used for ammonium and ammonia nitrogen concentration (SNH) in

the fifth tank (SNH,5) cascade control by manipulating the SO,5 set-

point, also by using BSM1 as testing plant. The fuzzy inference sys-

tem is employed in Pai et al. [22] to improve artificial neural net-

work to predict the total suspended solids (TSS) and the chemi-

cal oxygen demand (COD) in the effl uent from a hospital WWTP.

By using BSM2 as a working scenario, Santín et al. [23] Santín et

al. [24] apply fuzzy control to deal with pollutants limits viola-

tions. Fuzzy logic has also been applied for evaluation (Kalavrouzi-

otis et al. [25]) or management (Hirsch et al. [26]) of real WWTPs.

However, none of the referred papers have taken into account GHG

emissions.

Although there is a large number of works that apply control

strategies in WWTPs, the evaluation of GHG emissions has emerged

in recent years. Some works that analyze GHG emissions in WWTPs

by applying control strategies are Flores-Alsina et al. [7,8] and Barbu

et al. [27]. They use BSM2G, but with different model versions.

Flores-Alsina et al. [7] tests the effect of traditional control strate-

gies in GHG emissions, but without considering those produced by

nitrification. Flores-Alsina et al. [8] shows the effect on GHG emis-

sions of the different areas of a WWTP. Barbu et al. [27] presents the

effects of other traditional control strategies on water quality, opera-

tional costs and, especially, on GHG emissions, by an integral indica-

tor for performance evaluation. However, it was not the goal of these

works to implement specific control strategies in order to reduce N2O

emission in the nitrification process. On the other hand, Santín et

al. [28] reduce N2O emissions combining cascade SNO2

control and

cascade SNH,5 control. Boiocchi et al. [29] reduce N2O emissions with

a fuzzy controller that manipulates the oxygen transfer coeffi cient

(KLa) of the aerobic reactors based on SNH and the nitrate concen-

tration (SNO3

) in the input and in the output of the nitrification pro-

cess. In addition, Boiocchi et al. [29] take into account the effect that

the oxygen aeration can produce on effl uent costs and quality. Santín

et al. [28] combine two control strategies with PI controllers to also

reduce costs and improve the effl uent quality, but without attempt-

ing to eliminate nutrient violations. Both articles only manipulate

KLa of the aerobic reactors and only reduce SNO2

as GHG emissions.

The present article reduces the SNO2

emissions using a different

control strategy than the two referred articles, by means of only](https://image.slidesharecdn.com/fuzzy-logic-for-plant-wide-control-of-biological-wastewater-tr2018isa-tran-191011175840/75/Fuzzy-logic-for-plant-wide-control-of-biological-wastewater-treatment-process-including-greenhouse-gas-emissions-2-2048.jpg)

![148 I. Santín et al. / ISA Transactions 77 (2018)146–166

Fig. 1. BSM2 plant with notation used for flow rates.

SNH sensors, which are commonly used in real plants. The proposed

controller not only manipulates SO in the third reactor (SO,3), SO in

the fourth reactor (SO,4) and the SO,5 set-points, but also the inter-

nal recirculation flow rate (Qa), the external carbon flow rate (qEC)

in the first reactor (qEC,1) and the flow rate from the storage tank

(Qst). This fact also allows the proposed paper to differentiate itself

from the mentioned referenced articles, by reducing the CO2 emis-

sions due to the endogenous respiration of biomass, CO2 generated

from the external carbon source production and CO2 due to the elec-

tric consumption, and by removing the limit violations of the nutri-

ents. The proposed control strategies also differ from the literature,

achieving these objectives (together with the reduction of costs) by

the implementation of a single fuzzy controller, which to the best

of the authors knowledge has not been previously proposed. Also, it

has to be emphasized the addition of the derivatives of some vari-

ables with respect to time as fuzzy controller inputs, in order to

act in advance. In addition, the temperature is also considered as a

fuzzy controller input, since higher temperature means higher GHG

emissions (Boiocchi et al. [29]) and lower temperature means more

total nitrogen concentration (SNtot

) and SNH are generated. The article

explains the contribution of each manipulated variable in the pro-

posed objectives, as well as the effects of each of the fuzzy controller

al. [14]) that includes GHG emissions. The model was presented in

Flores-Alsina et al. [7] and an updated version provided by the same

authors has been used for the present article. Within these modifica-

tions, it is included the incorporation of the AOB denitrification path-

way for N2O emissions based on Guo and Vanrolleghem [12]. There-

fore, the present BSM2G includes two pathways for N2O emissions

(heterotrophic denitrification and AOB denitrification).

2.1. Layout

The BSM2G layout (Fig. 1) is designed for an influent with an aver-

age flow rate of 20,648.36 m3

/d and an average biodegradable COD of

592.53 mg/l. In the same way as in the case of BSM2, BSM2G is made

up of a primary clarifier, a secondary treatment and a sludge treat-

ment. The secondary treatment includes the biological reactors and

a secondary settler.

For the biological treatment, BSM2G includes, as in BSM1 (Copp

[13]) and BSM2, five biological reactors, two of which are anoxic

and three are aerobic. The biological reactions inside the reactors are

modeled by the Activated Sludge Model no 1 (ASM1) (Henze et al.

[30]). In BSM2G, ASM1 is extended on the basis of Hiatt and Grady

[31] and Mampaey et al. [32] in order to include, besides SNO , the

input. It should be noted that the proposed fuzzy control looks for a 3

other compounds that are present in the nitrification and deni tri-

trade-off between the aforementioned objectives, achieving satisfac- fication processes: SNO , nitric oxide (SNO), N2O and dinitrogen (N2).

tory results and without meaningfully worsening any of them. 2There is an internal r tion from the last aerobic reactor to feed

The paper is organized as follows. First, BSM2G working scenario

is presented. Next, the default and the proposed control strategies

are explained. Afterwards, simulations results are shown, together

with the discussion about them. Finally, the most important conclu-

sions are drawn.

2. Materials and methods

A benchmark is used for the evaluation of the proposed con-

trol strategy, as it is a common practice in wastewater treatment

research. This is BSM2G, which is an extension of BSM2 (Gernaey et

ecircula

the first anoxic reactor with SNO3

. The secondary clarifier is mod-

eled as a 10 layers non-reactive unit. At lower levels the sludge is

deposited by gravity. Some of this sludge is recirculated to the first

anoxic reactor (external recirculation) and the other part is led to be

treated. The hydraulic retention time of the primary clarifier and the

secondary treatment is 22 h. It is based on the average dry weather

flow rate and the volume of the primary clarifier (900 m3

), the bio-

logical reactors (12,000 m3

) and the secondary settler (6000 m3

). The

volume of each of the two anoxic tanks is 1500 m3

and the volume

of each of the three aerobic tanks is 3000 m3

.](https://image.slidesharecdn.com/fuzzy-logic-for-plant-wide-control-of-biological-wastewater-tr2018isa-tran-191011175840/75/Fuzzy-logic-for-plant-wide-control-of-biological-wastewater-treatment-process-including-greenhouse-gas-emissions-3-2048.jpg)

![I. Santín et al. / ISA Transactions 77 (2018)146–166 149

Table1

Limits for the effl uent pollutants.

Variable Value

SNtot

<18 mg/l

CODt <100 mg/l

SNH <4 mg/l

TSS <30 mg/l

BOD5 <10 mg/l

For the sludge treatment, BSM2G makes use of a thickener, an

anaerobic digester and a dewatering unit. The water extracted from

the sludge by the dewatering process is recirculated to the primary

clarifier through the storage tank to regulate its flow rate.

The influent data in BSM2G includes rainfall and storm events, as

well as variations in temperature. It is defined for 609 days, but only

the results of the period from day 245 to day 609 are considered for

evaluation. With the aim to stabilize the plant, a constant influent is

applied to the plant for 200 days, before any simulation.

2.2. Evaluation criteria

The performance of the control strategies is evaluated by consid-

ering the effl uent quality, the operational costs and the GHG emis-

sions.

The evaluation criteria for the effl uent quality are the percentage

of time for which the values of the effl uent pollutants are over the

established limits and the Effl uent Quality Index (EQI). Table 1 shows

the limits established for the effl uent concentrations of SNtot

, total

COD (CODt), SNH, TSS and 5-day Biological Oxygen Demand (BOD5) In

BSM2G, SNtot

is the sum of SNO3

, SNO2

, SNO, SN2O

and Kjeldahl nitrogen

(SNKj), which includes the organic nitrogen and SNH. Within these

concentrations, this article only evaluates the violations of SNtot

in

the effl uent (SNtot,e

) and SNH in the effl uent (SNH,e). This is due to the

fact that the rest of the concentrations are commonly kept under the

established limits and they only exceed the limits in exceptional days

when the high increase of the influent flow makes the wastewater be

bypassed to the effl uent without being treated.

EQI is expressed in Kg of pollutants per day and is calculated

weighting the effl uent concentration of the different pollutants,

according to the following expression:

t=609days

treatment, the sludge treatment, the difference between electric con-

sumption and electric generation, the EC production and the sludge

to be disposed. Within these sources, with the control strategy pro-

posed in this article, those produced in the biological treatment, due

to electricity and due to EC production are attempted to be reduced

and then evaluated.

3. Control approach

The control approach proposed in this article is mainly based on

a single fuzzy controller that manipulates the variables of the water

line in a WWTP. However, although the work is focused on this fuzzy

controller, three PI controllers are also applied in order to control

SO,3, SO,4 and SO,5 by manipulating KLa in the third tank (KLa3), in

the fourth tank (KLa4) and in the fifth tank (KLa5). Each one of them

controls the SO of one reactor by manipulating the KLa of the same

reactor.

Due to the large number of inputs and outputs of the pro-

posed fuzzy controller, it has been elaborated incrementally in order

to observe the effect produced by the different manipulated and

measured variables. The fuzzy controller finally designed is called

fuzzy_plantwide and the intermediate fuzzy controllers are num-

bered from 1 to 4 (fuzzy_1, fuzzy_2, fuzzy_3 and fuzzy_4).

In order to compare the performance of the new proposals, the

default control strategy (DCS) used in BSM2G is considered the start-

ing point. The second part includes the explanations of the PI con-

trollers used at the basic level and the fuzzy controller. Fig. 2 shows

the configuration of DCS and the proposed control strategy.

For all the control strategies, ideal sensors have been considered,

as it is a common practice in the research made on benchmark sim-

ulation models.

3.1. Default control strategy (DCS)

As it is shown in Fig. 2a, the DCS closed-loop control configuration

consists of a PI controller that controls SO,4 at a set-point of 2 mg/l by

manipulating KL a3, KLa4 and KL a5 with KLa5 set to the half value of

KLa3 and KLa4. KL a values are constrained from 0 to 360 d−1

.

For other possible manipulated variables, a fixed value is applied.

qEC,1 is added at a constant flow rate of 2 m3

/d. For the rest of the

reactors there is no external carbon addition. Two different wastage

flow rate (Qw ) values are imposed depending on the time of the year:

from 0 to 180 days and from 364 to 454 days Qw is set to 300 m3

/d;

and for the remaining time periods Qw is set to 450 m3/d. Qa is fixed

EQI =

1

1000 · T ∫

t=245days

(2 · TSS(t) + COD(t) + 30 · SNKj(t)) + at 61,944 m3/d.

The tuning parameters of the PI controller implemented in DCS

are kp = 25 and Ti = 0.002. The tuning employed here is taken from

+ 10 · (SNO3

+ SNO2

+ SNO + SN2O

)(t) + 2 · BOD5(t)) · Q(t) · dt

(1)

Nopens et al. [33] in order to consider the same basic control loops

configuration as in the BSM2 default control strategy.

where T is the evaluation period and Q is the flow rate.

The operational costs are evaluated by the Operational Cost Index

(OCI). It is calculated weighting the different costs of a WWTP as fol-

lows:

OCI = AE + PE + 3 · SP + 3 · EC + ME − 6 · METprod + HEnet (2)

where AE is the aeration energy (kWh/d), PE is the pumping energy

(kWh/d), SP is the sludge production (kg/d), EC refers to the carbon

that could be added to improve denitrification (kg/d), ME is the mix-

ing energy (kWh/d), METprod is the produced methane (kWh/d) and

HE is the heating energy (kWh/d).

The GHG emissions are a new evaluation criterion of BSM2G with

respect to BSM2. They are calculated according to the principles pro-

posed by Hiatt and Grady [31] and Mampaey et al. [32]. The follow-

ing sources of GHG emissions are taken into account: the biological

3.2. Proposed control strategy

The proposed control strategy in this paper is mainly focused on

the implementation of fuzzy logic. The own authors’ experience in

WWTP control engineering and the opinions received from opera-

tors in real plants make the authors conclude that the experience

and knowledge of the plant behavior is of great importance in the

control strategies application in WWTPs. For this reason, the main

control proposed is based on a single fuzzy controller designed to

manipulate six variables of the water line based on different mea-

sured variables, as well as their time derivatives in some cases, to

know their trend over time. The fuzzy controller does not try to keep](https://image.slidesharecdn.com/fuzzy-logic-for-plant-wide-control-of-biological-wastewater-tr2018isa-tran-191011175840/75/Fuzzy-logic-for-plant-wide-control-of-biological-wastewater-treatment-process-including-greenhouse-gas-emissions-4-2048.jpg)

![150 I. Santín et al. / ISA Transactions 77 (2018)146–166

the measured variables at a given set-point, as in Santín et al. [20].

The configuration of the full proposed control strategy is shown in

Fig. 2b.

Within the manipulated variables of the fuzzy controller, Qa, qEC,1

and Qst are directly related to the actuator. However, SO in the

aerobic reactors are controlled by PI controllers, whose set-points

are manipulated by the fuzzy controller. These PI controllers are

explained in the next section.

3.2.1. PI controllers for SO control in the aerobic reactors

PI controllers aim to maintain a variable at a given set-point

(unlike the proposed fuzzy controller) and they are mostly used in

real plants. SO in the reactors are some of the few variables that can

be maintained at a set-point in a WWTP, without a large error. There-

fore, PI controllers are proposed for this objective. For the fuzzy logic,

it is easier and more coherent to find the relationship of SNH and SNO3

with SO in the aerobic reactors, than directly with KL a of the aerobic

reactors.

The tuning of these PI controllers as well as the controlled and

manipulated variables of each one are the same with those the

default PI controller (kp = 25 and Ti = 0.002). This is because their

tracking is satisfactory enough and the implementation objectives of

this article are focused on the fuzzy controller. KLa values are also

constrained from 0 to 360 d−1

as in DCS.

3.2.2. Fuzzy logic

Fuzzy logic can be defined as a control based on human exper-

tise, determined by words instead of numbers and sentences instead

of equations. However, process variables are measured in numbers

instead of words. For this reason, the fuzzy controller adapts the

input variables into suitable linguistic values by membership func-

tions (mf). For further information about the fuzzy control, the reader

is referred to standard references such as Klir and Yuan [34].

The proposed fuzzy controller has been initially tuned based on

the knowledge of the biological processes described by the extended

ASM1 and on a specific analysis of the evolution over time of the

fuzzy controller inputs. After that, the membership functions values

range have been adjusted by trial and error in order to optimize the

results. The proposed fuzzy controller has been designed and tested

progressively. It has been always implemented with a sampling time

of 15 min. The complete fuzzy controller is called fuzzy_plantwide,

which consists of 14 inputs, 6 outputs, and 80 fuzzy rules. For the

controller inputs, 8 sensors are required. As shown in Figs. 2b and

3, the fuzzy_plantwide inputs are SNH at the input of the biological

reactors (SNH,0), at the output of the second reactor (SNH,2), of the

third reactor (SNH,3), of the fourth reactor (SNH,4) and SNH,5, the sum

of SNO3

at the output of the fifth reactor (SNO3 5) and SNH,5, the tem-

perature (Tas), the input flow rate (Qin ), the product of Qin and SNH

at the input of the primary clarifier (SNH,in), as well as the deriva-

tive with respect to time of SNH,2 (dSNH,2/dt), SNH,3 (dSNH,3/dt), SNH,4

(dSNH,4/dt), the sum of SNH,5 and SNO3 5 (d(SNH,5+SNO3 5)/dt) and the

product of Qin and SNH,in (d(Qin·SNH,in )/dt). The fuzzy_plantwide out-

puts are the SO,3 set-point, the SO,4 set-point, the SO,5 set-point, Qa,

qEC,1 and Qst . Mamdani (Mamdani [35]) is the method of inference.

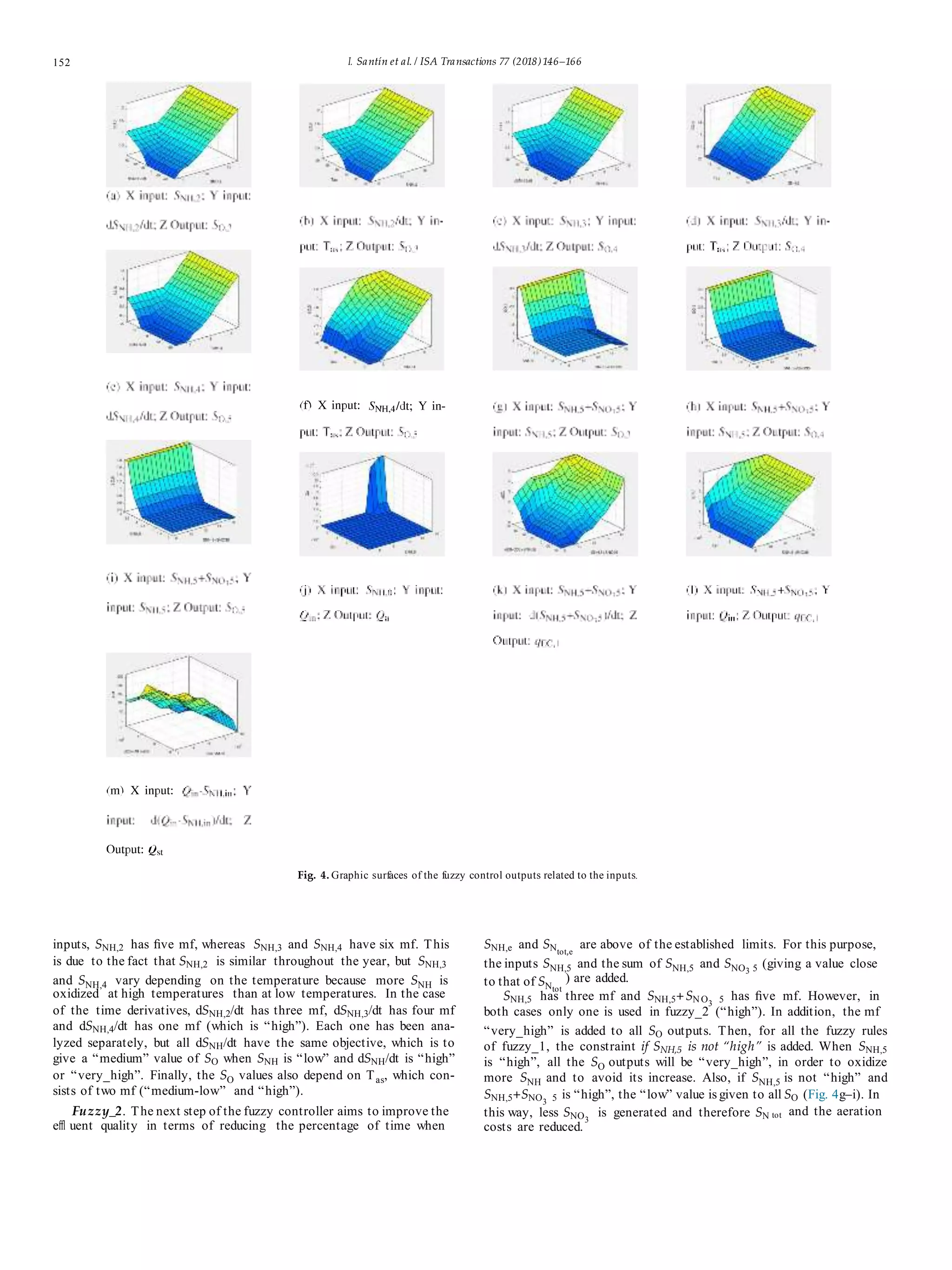

Fig. 4 shows the most relevant input-output relationships of the

fuzzy controller through surface graphs, which allows the observa-

tion of the non-linearity of the fuzzy controller. The regulation of the

fuzzy controller output variables is aimed to reduce GHG emissions,

to reduce costs and to improve the effl uent quality by reducing SNH,e

and SNtot,e

limit violations. However, the manipulation of each vari-

able has different objectives and there is no variable that tries to ful-

fill all the objectives only by itself. The value of the output variables

is obtained based on the input variables, by means of the so-called

fuzzy rules.

Fig. 2. Layouts ofDCS and fuzzy_plantwide.](https://image.slidesharecdn.com/fuzzy-logic-for-plant-wide-control-of-biological-wastewater-tr2018isa-tran-191011175840/75/Fuzzy-logic-for-plant-wide-control-of-biological-wastewater-treatment-process-including-greenhouse-gas-emissions-5-2048.jpg)

![I. Santín et al. / ISA Transactions 77 (2018)146–166 151

Fig. 3. Inputs and outputs offuzzy_1, fuzzy_2, fuzzy_3, fuzzy_4 and fuzzy_plantwide.

The 80 fuzzy rules relate the manipulated variables to the val-

ues of the measured variables. These input-output relationships are

based on the biological processes that take place during the wastew-

ater treatment, as well as on the plant operation experience. The rea-

sons for the choice of input-output relationships are explained in the

following paragraphs, for each one of the fuzzy controllers. The fuzzy

rules code is presented in appendix A and explained by a scheme in

appendix B. The FIS1

Editor from Matlab, used for the implementa-

tion of the fuzzy controllers, has some constrains in applying differ-

ent conditions. This fact requires the definition of a big number of

fuzzy rules that could be significantly reduced with a more flexible

tool.

In order to know the effect produced in the plant by the differ-

ent inputs and outputs, the controller has been tested and explained

incrementally by different steps until the fuzzy_plantwide has been

implemented. To this end, the fuzzy controllers have been numbered

from 1 to 4, as inputs and/or outputs have been added. Fig. 3 show

the inputs and outputs of each of these fuzzy controllers. The code

of fuzzy_plantwide is shown in Appendix A. The objectives sought in

each of the fuzzy controllers, as well as the reasons for their applica-

tion, are explained below.

Fuzzy_1. The main objective of fuzzy_1 is to reduce N2O emis-

sions, which are an important factor of GHG emissions. Higher N2O

emissions are generated during nitrification. As shown in several

articles such as Kimochi et al. [3], Kampschreur et al. [4], Foley et

al. [5], Law et al. [6], Flores-Alsina et al. [7,8], Aboobakar et al. [9] or

Wang et al. [10], N2O emissions during nitrification are the result of

partial nitrification. It happens when the SNH oxidation is not com-

pletely converted to SNO3

. Therefore, N2O emissions are related to SO

in the aerobic reactors (Boiocchi et al. [29]).

Therefore, the first application of the fuzzy controller is created

with the intention to avoid partial nitrification. Fuzzy_1 manipulates

the SO set-points of the aerobic reactors based on the SNH input of

each reactor. SO set-points are constrained from 0 to 5 mg/l. The SO

values are finally obtained by the PI controllers, whose set-points

are given by the fuzzy controller. Then, knowing the SNH input of a

reactor and based on the experience of the plant, the required SO is

added by the fuzzy controller for complete nitrification. In addition,

not only the values of SNH, but also their slopes are taken into account

by their derivatives with respect to time. This allows the controller to

be able to act in advance. In the case of fuzzy_1, when SO is low and

SNH begins to increase, the increase of SO has to be fast. Otherwise,

a very large increase of N2O can be produced. For this reason, the

derivative of SNH with respect to time (dSNH/dt) is taken into account,

mainly when the values of SNH are low in order to detect their immi-

nent increase (Fig. 4a, c and e). Finally, the resulting SO values are also

influenced by temperature, because N2O emissions are much higher

at high temperatures (Fig. 4b, d and f). It is important to note the dif-

ference between fuzzy_1 and the cascade SNH control widely used in

the literature (Vrecko et al. [36], Stare et al. [37], Flores-Alsina et al.

[7], Barbu et al. [27], etc.), because although this can achieve better

effl uent quality results, N2O emissions are not considered and par-

tial nitrification can occur, as high GHG emission values are shown

in Barbu et al. [27] by SNH,5 cascade control.

Although the main objective of fuzzy_1 is the reduction of the N2O

emissions, the levels of SNH and SNO3

are also taken into considera-

tion to some extent, since SO is regulated based on the SNH values.

In fuzzy_1 the outputs SO,3, SO,4 and SO,5 have five member-

ship functions, since “very_high” is added in fuzzy_2. Regarding the

1

FIS: Fuzzy Inference System.](https://image.slidesharecdn.com/fuzzy-logic-for-plant-wide-control-of-biological-wastewater-tr2018isa-tran-191011175840/75/Fuzzy-logic-for-plant-wide-control-of-biological-wastewater-treatment-process-including-greenhouse-gas-emissions-6-2048.jpg)

![I. Santín et al. / ISA Transactions 77 (2018)146–166

The input SNH,5+SNO3 5 is not added as a constraint in the fuzzy

rules of fuzzy_1, because that could imply an increase of N2O by

reducing SO.

Fuzzy_3. In the following fuzzy controller application, Qa is added

as output, while Qin and SNH,0 are added as inputs. The manipulation

of Qa aims to reduce the SNH peaks and it is not only based on Qin and

SNH,0, but also on SNH,5. Qa is constrained from 0 to 309,720 m3

/d

and, in addition, its variations are also constrained to 26,000 m3

/d

between two samples (15 min) in order not to have abrupt changes.

Qin has one mf (“high”), which is above the usual ranges of dry

weather and, thus, the values of this mf happen when there is rain-

fall event. SNH,0 also has only one mf called “high” and Qa three mf

(“low”, “medium” and “high”). Then, by fuzzy rules, when SNH,5 is

increased close to the limit, Qa is reduced in order to increase the

hydraulic retention time (HRT) and thus improve the nitrification

process. On the other hand, when there is a Qin increase due to a

rainfall and, at that time SNH,0 is “high” while SNH,5 is “low”, Qa is

increased to dilute the SNH concentration (Fig. 4j). When the SNH

peak reaches the aerobic reactors, detected as a result of SNH,5 being

“high”, Qa is reduced.

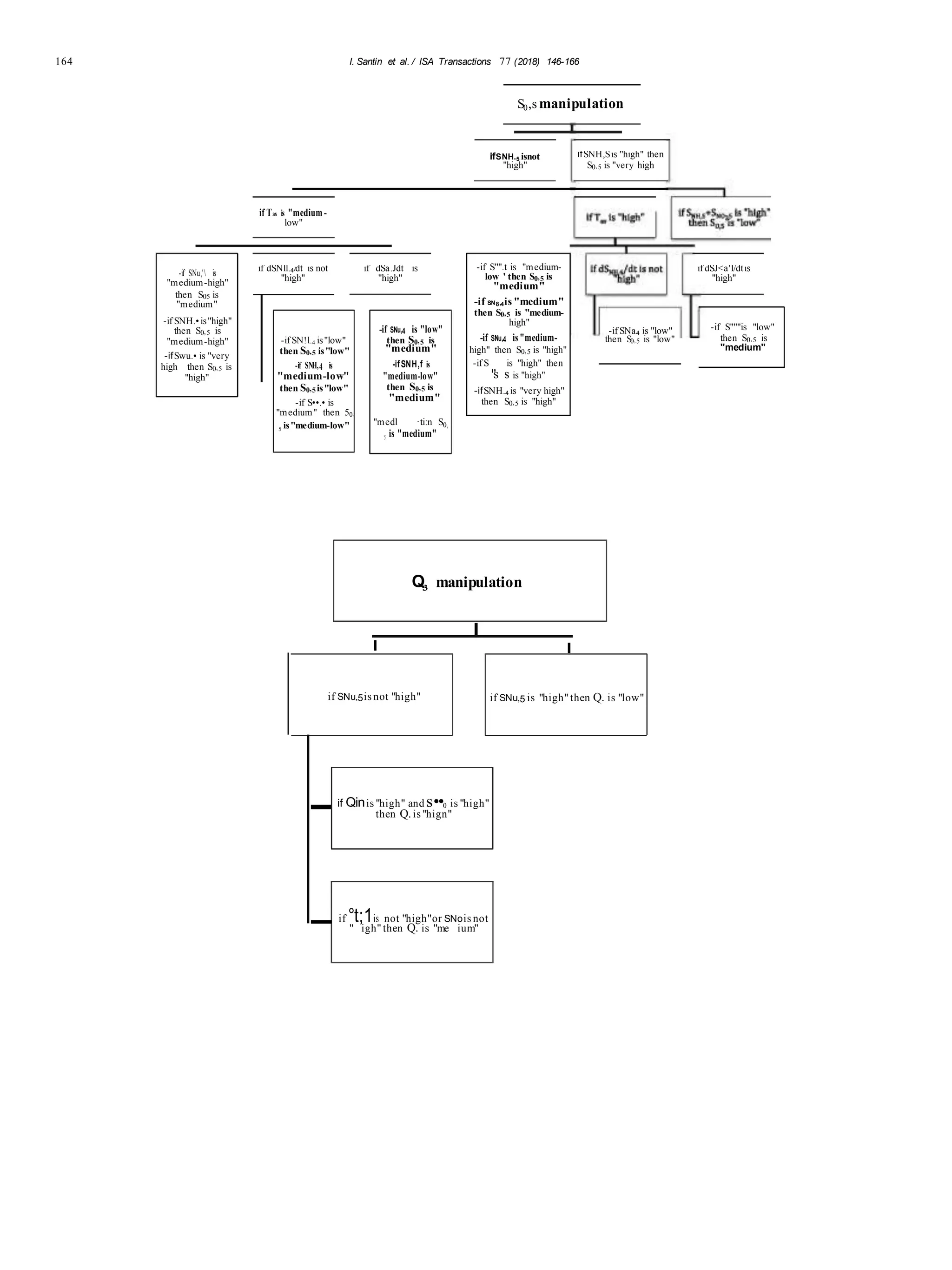

Fuzzy_4. In fuzzy_4, qEC,1 is added as an output. This is intended to

regulate the addition of qEC,1 instead of keeping it fixed at 2 m3

/d. The

addition of qEC improves the denitrification, significantly reducing

SNO3

values, but on the contrary, it increases the operational costs.

In addition, although a slight decrease of N2O in denitrification can

be produced when external carbon is added, the total GHG emis-

sions are higher due to an increase in the endogenous respiration

of biomass, in the sludge processing and in the chemical and energy

use. Due to these reasons, fuzzy_4 aims to add carbon only in the

cases where a reduction of SNtot,e

is necessary. In this way, the value

of qEC,1 added in fuzzy_4 is based on SNH,5+SN O3 5 and its time deriva-

tive (Fig. 4k). In addition, Qin is also taken into account, since its value

is increased when there is a rainfall, qEC,1 is also increased (Fig. 4l).

The value of qEC,1 is constrained from 0 to 5 m3

/d.

Five mf of the input SNH,5+SNO35 are related to five mf of the

output qEC,1. In the case of d(SNH,5+SNO3 5)/dt, it has three mf and

it is considered both to increase the values of qEC,1 and to reduce

them. So, when the mf of Qin is not active because there is no

rainfall, if d(SNH,5+SNO3 5)/dt is “medium”, the relationship between

SNH,5+SNO3 5 and qEC,1 is as follows: if SNH,5+SNO35 is “low” then qEC,1

is “low”, if SNH,5+SNO3 5 is “medium” then qEC,1 is “medium” and so

on. In the event that d(SNH,5+SNO3 5 )/dt is “high”, qEC,1 is previ-

ously increased to act in advance against SNtot,e

limit violations. If

d(SNH,5+SNO3 5)/dt is “low”, the value of qEC,1 is lower to save carbon

costs. If Qin is “high”, the values of qEC,1 in relation to SNH,5+SNO3 5 and

d(SNH,5+SNO3 5)/dt are also increased.

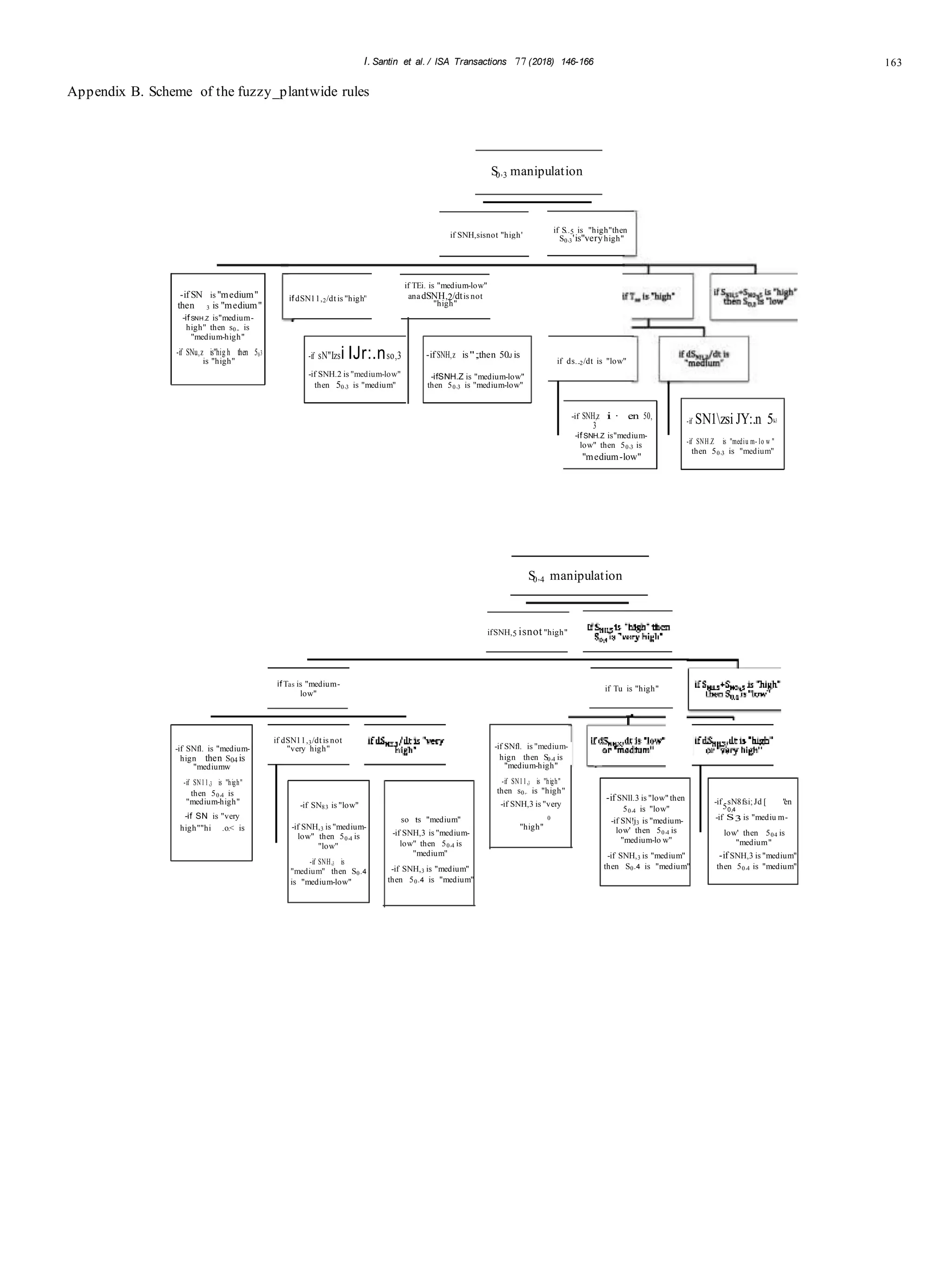

Fuzzy_plantwide. Finally, the fuzzy controller is fully imple-

mented, which is called fuzzy_plantwide. The fuzzy_plantwide code

is shown in Appendix A and a scheme of its fuzzy rules is in

Appendix B. The last application of the fuzzy controller adds Qst as

a manipulated variable. This is based on the product of Qin and SNH,in

and its derivative with respect to time.

The storage tank is responsible for regulating the amount of

water that is recirculated from the dewatering to the primary settler.

Although the amount of recirculated water is very low in comparison

to the influent, its SNH is very high.

First of all, the default operation of the storage tank has been par-

tially modified. As explained in the previous section, in the default

operation, when the water volume of the tank is below or equal to

the minimum established value, all the flow leads into the tank while

Qst is equal to 0. This has been modified in order to fill the tank if it

is necessary. In such a way that all the flow is led by bypass if Qst

is higher than the input flow. On the other hand, if the given Qst is

lower than the input flow, Qst will be equal to the given value and the

tank will be filled by the difference between the inlet and the out-

153

Table2

Simulationresultsofthedefaultcontrolstrategy,literatureandtheproposedfuzzycontrollersaswellaspercentagesofimprovementwithrespecttothedefaultcontrolstrategy.

EvaluationCriteriaDCSSantínetal.[28]fuzzy_1fuzzy_2fuzzy_3fuzzy_4Fuzzy_plantwide

valuevalue%of

improvement

85.09

value%of

improvement

87.55

value%of

improvement

88.77

value%of

improvement

89.24

value%of

improvement

94.81

value%of

improvement

98,96EffluentqualitySNtot,eviolations

(%ofoperatingtime)

SNH,eviolations

(%ofoperatingtime)

EQI(kgofpollutants/d)

10.61.721.321.191.140.550.11

1.140.05438.570.1289.470.06694.21010001000100

5665.985469.223.475490.453.105489.193.125486.983.165595.431.245567.771.73

OperationalcostsAE(kWh/d)

PE(kWh/d)

EC(kg/d)

OCI

4306.25

261.48

800

9272.78

–

–

–

8635.33

–

–

–

6.94

3788.46

261.48

800

8737.47

12.02

0

0

5.78

3786.08

261.48

800

8735.08

12.08

0

0

5.80

3782.05

263.71

800

8733.22

12.17

−0.85

0

5.82

3701.54

263.74

546.12

7839.63

14.04

−0.86

31.73

15.45

3639.85

263.73

5015.01

7677.35

15.47

−0.86

35.62

17.20

GHGemissionsN2Obiotreatment(kgCO2equiv-

alent/d)

Endogenousrespirationof

biomass(kgCO2/d)

Totalbiotreatment(kgCO2/d)

PowerCredit(kgCO2/d)

EC_GHG(kgCO2/d)

TotalCO2(KgCO2/d)

1596.21197.7922.17773.3751.55782.9250.95786.6650.72801.9249.76858.2846.23

3563.83––3541.010.643540.980.643540.890.643455.733,.033443.693.37

9086.11

−505.85

821.33

17,851.1

–

–

–

17,134.19

–

–

–

4.02

8243.59

−738.91

821.33

16,753.28

9.27

46.07

0

6.15

8253.15

−740.01

821.33

16,761.64

9.18

46.29

0

6.10

8256.82

−740.83

821.33

16,764.53

9.13

46.45

0

6.09

8187.67

−755.23

560.68

16,339.12

9.89

49.30

31.73

8.47

8231.31

−781.23

528.34

16,315.06

9.41

54.44

35.67

8.60](https://image.slidesharecdn.com/fuzzy-logic-for-plant-wide-control-of-biological-wastewater-tr2018isa-tran-191011175840/75/Fuzzy-logic-for-plant-wide-control-of-biological-wastewater-treatment-process-including-greenhouse-gas-emissions-8-2048.jpg)

![154 I. Santín et al. / ISA Transactions 77 (2018)146–166

let flow while the volume does not reach its maximum established

value.

Once the operation of the storage tank has been modified,

fuzzy_plantwide controller aims to compensate the Qin ·SNH,in peaks

by reducing Qst . Conversely, when the values of Qin ·SNH,in are lower,

Qst is increased to empty the storage tank. Qst is constrained from 0

to 1500 m3

/d.

Both Qin ·SNH,in and Qst have five mf, whereas d(Qin·SNH,in)/dt

has three mf. When d(Qin·SNH,in )/dt is “medium” the relationship

between Qin ·SNH,in and Qst is completely reversed (if Qin ·SNH,in is

“low” then Qst is “high”, if Qin ·SNH,in is “medium-low” then Qst is

“medium-high”, etc). In the case of d(Qin·SNH,in)/dt is “low”, Qst is

higher. Conversely, if d(Qin·SNH,in)/dt is “high”, the values of Qst are

lower (Fig. 4m).

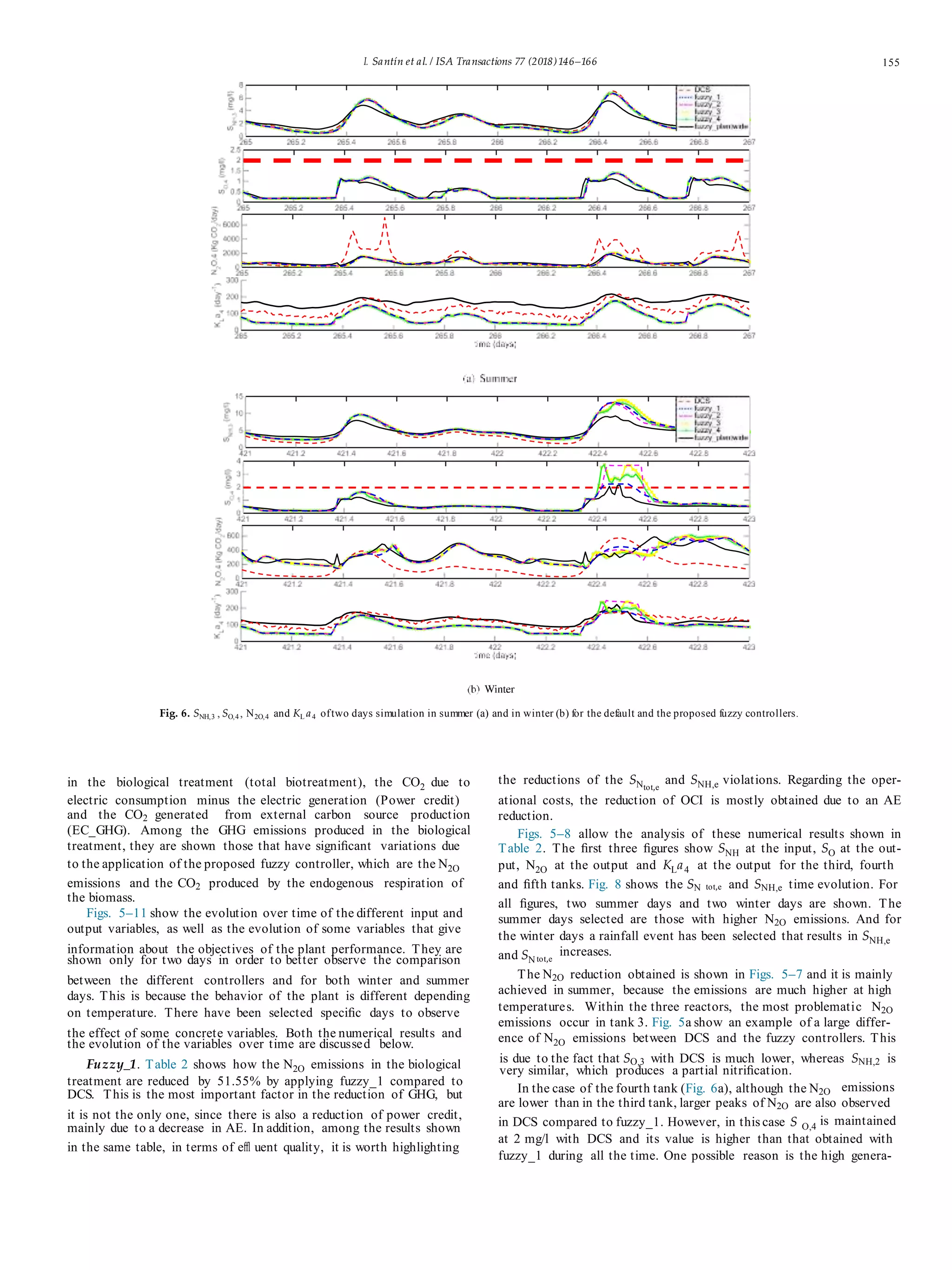

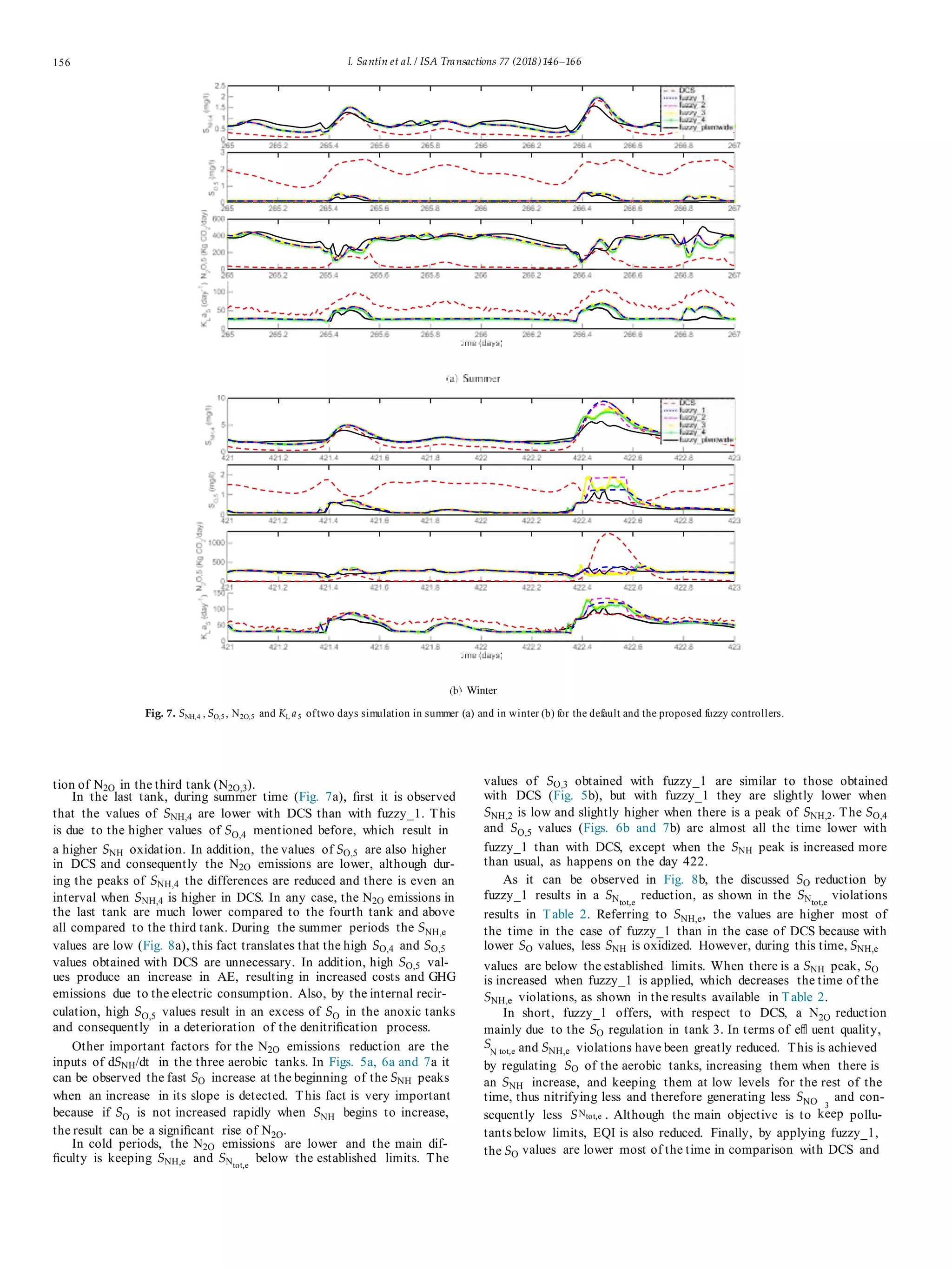

4. Simulation results and discussion

This section presents the simulation results and the discussion

regarding the fuzzy controller. As well as in the previous section, the

results have been analyzed for each one of the fuzzy controllers that

have been implemented incrementally in order to observe the effects

of the different inputs, outputs and fuzzy rules.

Table 2 shows the results obtained with fuzzy_1, fuzzy_2, fuzzy_3,

fuzzy_4 and fuzzy_plantwide, as well as the results of Santín et al.

[28] and DCS. The latter has been used as reference for the percentage

of improvement. The articles Flores-Alsina et al. [7,8] and Boiocchi et

al. [38] also include the GHG emissions assessment, but they have

not been considered for comparison because the first two articles

use the original BSM2G and the last one uses BSM2 for Nitrous oxide

(BSM2N). In the case of Barbu et al. [27] and Santín et al. [28], they

are the only papers that use the same updated BSM2G as the present

article. Although Barbu et al. [27] evaluates GHG emissions, it does

not implement a specific control strategy to reduce them, resulting

in higher GHG emissions than by applying DCS. Therefore, Barbu et

al. [27] has neither been considered for comparison, since the main

objective of the present article is the reduction and consequently, the

first step before considering other criteria.

Effl uent quality has been evaluated through the percentage of

time of SNtot,e

and SNH,e limit violations. Although the main objective

in terms of quality is to keep contaminants below the established

limits, EQI is also shown as a criterion to be compared. COD, TSS and

BOD5 limit violations are not shown because they only occur on cer-

tain days when there is a bypass and this is not modified with the

proposed fuzzy controller.

Within the operational costs, there are shown those that have

significant variations. These are especially AE and EC, but PE is also

shown because Qa is regulated from fuzzy_3.

Regarding the GHG emissions, in addition to the total CO2, the

emissions of the sources that have significant variations with the

proposed fuzzy controller are also shown. These are those produced

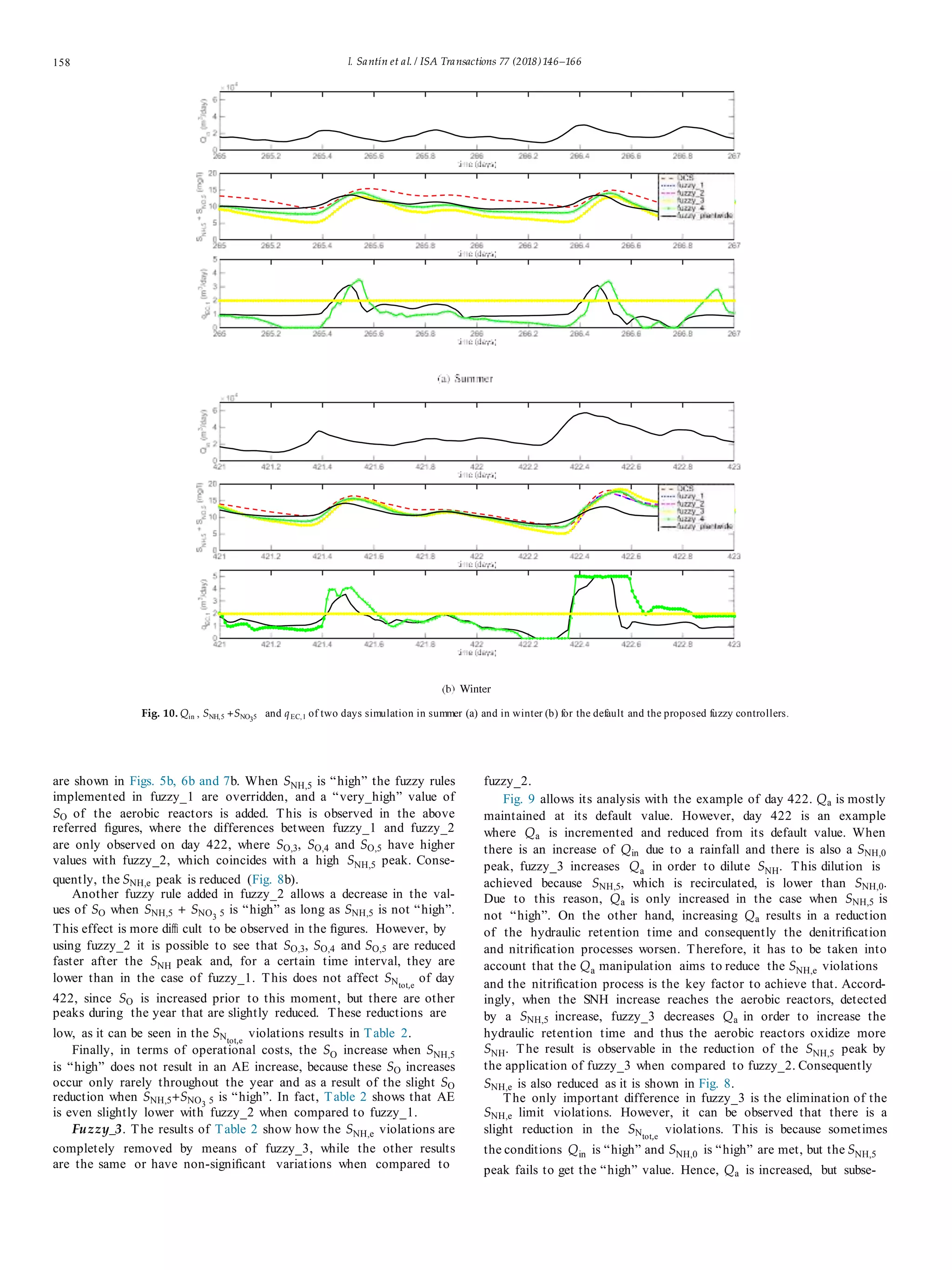

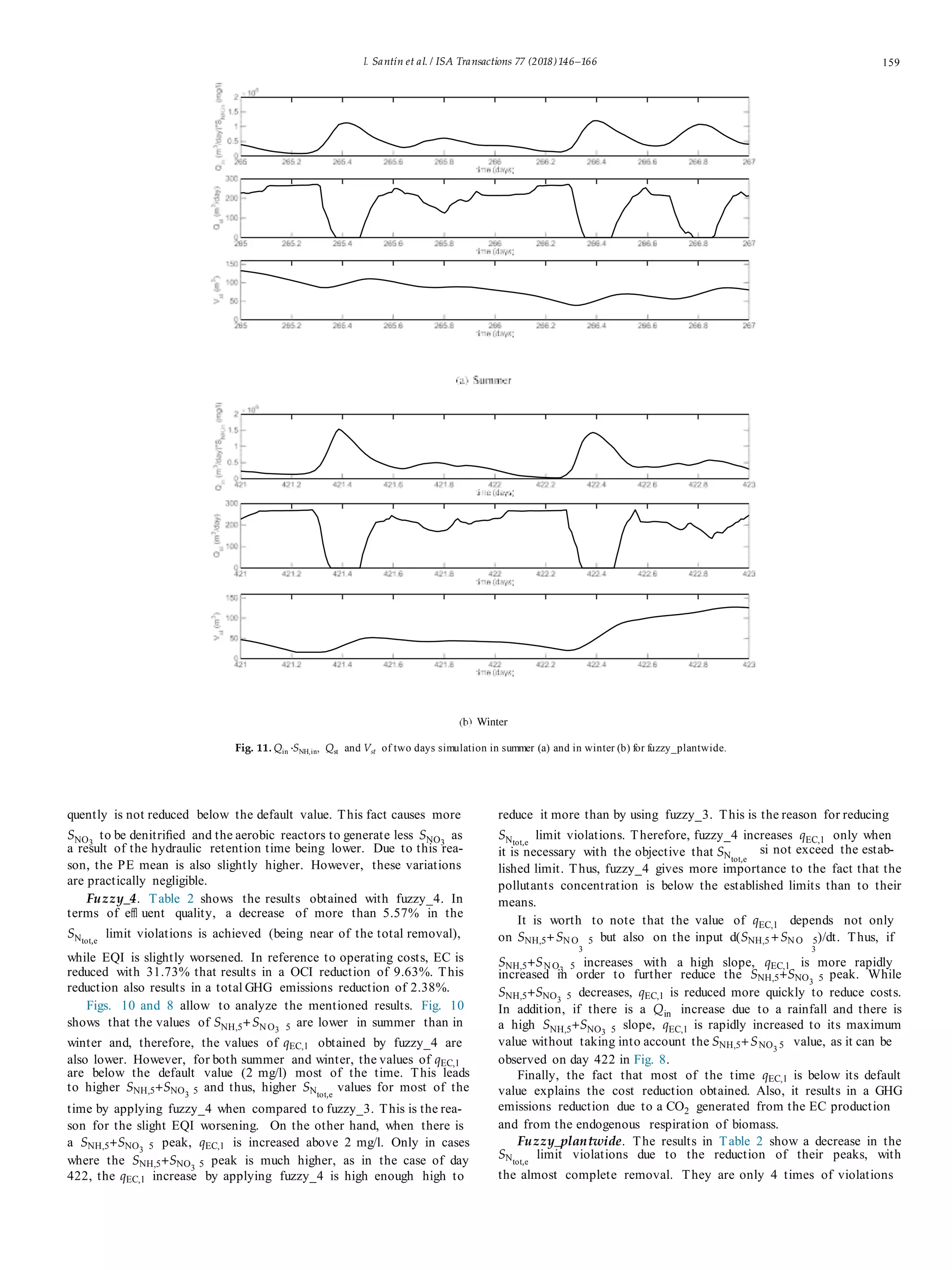

Fig. 5. SNH,2 , SO,3 , N2O,3 and KL a3 oftwo days simulation in summer (a) and in winter (b) for the default and the proposed fuzzy controllers.](https://image.slidesharecdn.com/fuzzy-logic-for-plant-wide-control-of-biological-wastewater-tr2018isa-tran-191011175840/75/Fuzzy-logic-for-plant-wide-control-of-biological-wastewater-treatment-process-including-greenhouse-gas-emissions-9-2048.jpg)

![I. Santín et al. / ISA Transactions 77 (2018)146–166 161

Appendix A. Fuzzy_plantwide code

[System]

Name = ’ Fuzzy_plantwide ’

Type = ’ mamdani ’

Version = 2.0

NumInputs = 14

NumOutputs = 6

NumRules = 80

AndMethod = ’ min ’

OrMethod = ’ max ’

ImpMethod = ’ min ’

AggMethod = ’ max ’

DefuzzMethod = ’ centroid ’

[Input1]

Name = ’ SNH,2 ’

Range = [4 18]

NumMFs = 5

MF1 = ’ low ’ : ’trimf’ , [−1000000 4 7.5]

MF2 = ’ medium−low ’ : ’ trimf’ , [4 7.5 11]

MF3 = ’ medium’ : ’ trimf ’ , [7.5 11 14.5]

MF4 = ’ medium−high ’ : ’ trimf’ , [11 14.5 18]

MF5 = ’ high ’ : ’ trimf’ , [14.5 18 1000000]

[Input2]

Name = ’ SNH,3 ’

Range = [1 12]

NumMFs = 6

MF1 = ’ low ’ : ’ trimf’ , [−1000000 2 3.2]

MF2 = ’ medium−low ’ : ’ trimf’ , [2 3.2 5.4]

MF3 = ’ medium’ : ’ trimf’ , [3.2 5.4 7.6]

MF4 = ’ medium−high ’: ’ trimf’ , [5.4 7.6 9.8]

MF5 = ’ high ’ : ’ trimf’ , [7.6 9.8 12]

MF6 = ’ very_high ’ : ’ trimf’ , [9.8 12 1000000]

[Input3]

Name = ’ SNH,4 ’

Range = [1 7]

NumMFs = 6

MF1 = ’ low ’ : ’ trimf’ , [−1000000 1 2.2]

MF2 = ’ medium−low ’ : ’ trimf’ , [1 2.2 3.4]

MF3 = ’ medium’ : ’ trimf’ , [2.2 3.4 4.6]

MF4 = ’ medium−high ’: ’ trimf’ , [3.4 4.6 5.8]

MF5 = ’ high ’ : ’ trimf’ , [4.6 5.8 7]

MF6 = ’ very_high ’ : ’ trimf’ , [5.8 7 1000000]

[Input4]

Name = ’ dSNH,2/dt ’

Range = [−50 75]

NumMFs = 3

MF1 = ’ low ’ : ’ trimf’ , [−1000000 −50 0]

MF2 = ’ medium’ : ’ trimf ’ , [−37.5 12.5 62.5]

MF3 = ’ high ’ : ’ trimf’ , [25 75 1000000]

[Input5]

Name = ’ dSNH, 3 / dt ’

Range = [−40 60]

NumMFs = 4

MF1 = ’ low ’ : ’ trimf’ , [−1000000 −40–6.667]

MF2 = ’ medium’ : ’ trimf ’ , [−40 −6.667 26.67]

MF3 = ’ high ’ : ’ trimf’ , [20 40 60]

MF4 = ’ very_high ’ : ’ trimf’ , [26.67 60 1000000]

[Input6]

Name = ’ dSNH, 4 / dt ’

Range = [−20 20]

NumMFs = 1

MF1 = ’ high ’ : ’ trimf’ , [10 20 1000000]

(continued on nextpage)

[System]

[Input7] Name

= ’ Tas ’

Range = [10 20]

NumMFs = 2

MF1 = ’ medium− low ’ : ’ trimf ’ , [−1000000 15 20]

MF2 = ’ mf3 ’ : ’ trimf’ , [15 20 1000000]

[Input8]

Name = ’ SNH, 5 ’

Range = [1 4]

NumMFs = 3

MF1 = ’ low ’ : ’ trimf’ , [−1000000 1 2.2]

MF2 = ’ medium’ : ’ trimf’ , [1.3 2.25 3.2]

MF3 = ’ high ’ : ’ trimf’ , [3 3.75 1000000]

[Input9]

Name = ’ SNH, 5 + SNO35 ’

Range = [8 17]

NumMFs = 5

MF1 = ’ low ’ : ’ trimf’ , [−1000000 8 10.26]

MF2 = ’ medium− low ’ : ’ trimf’ , [8 10.26 12.5]

MF3 = ’ medium’ : ’ trimf’ , [10.26 12.5 14.76]

MF4 = ’ medium−high ’ : ’ trimf’ , [12.5 14.76 17]

MF5 = ’ high ’ : ’ trimf’ , [14.76 17 1000000]

[Input10] Name

= ’SNH,0’

Range = [5 14]

NumMFs = 1

MF1 = ’ high ’ : ’ trimf’ , [12 14 1000000]

[Input11]

Name = ’Qin’

Range = [2000 50000]

NumMFs = 1

MF1 = ’ high ’ : ’ trimf’ , [45000 50000 1e+15]

[Input12]

Name = ’ d(SNO35 + SNH,5)/dt ’

Range = [−40 80]

NumMFs = 3

MF1 = ’ low ’ : ’ trimf’ , [−1000000 −40 8]

MF2 = ’ medium’ : ’ trimf’ , [−28 20 68]

MF3 = ’ high ’ : ’ trimf’ , [52.31 80 1000000]

[Input13]

Name = ’ QinSNHin ’ Range

= [200000 1000000]

NumMFs = 5

MF1 = ’ low ’ : ’ trimf’ ,[−1e+16 200000 400000]

MF2 = ’ medium − low ’ : ’ trimf’ , [200000 400000 600000]

MF3 = ’ medium ’ : ’ trimf ’ , [400000 600000 800000]

MF4 = ’ medium−high ’ : ’ trimf’ , [600000 800000 1000000]

MF5 = ’ high ’ : ’ trimf’ , [800000 1000000 1e+16]

[Input14]

Name = ’ d(QinNHin) / dt ’

Range = [−5000000 10000000]

NumMFs = 3

MF1 = ’ low ’ : ’ trimf ’ ,[−1e+17 −5000000 1000000]

MF2 = ’ medium’ : ’ trimf ’ , [−3500000 2500000 8500000]

MF3 = ’ high ’ : ’ trimf ’ , [4000000 10000000 1e+17]

[Output1] Name

= ’ SO, 3 ’

Range = [0 4]

NumMFs = 6

MF1 = ’ low ’ : ’ trimf’ ,[−1000000 0 0.5625]

MF2 = ’ medium− low ’ : ’ trimf’ , [0 0.5625 1.125]

MF3 = ’ medium’ : ’ trimf ’ , [0.5625 1.125 1.688]

MF4 = ’ medium−high ’ : ’ trimf’ , [1.125 1.688 2.25]

MF5 = ’ high ’ : ’ trimf’ , [1.688 2.25 2.813]

MF6 = ’ very_high ’ : ’ trimf’ , [3 3.75 1000000]

(continued on nextpage)](https://image.slidesharecdn.com/fuzzy-logic-for-plant-wide-control-of-biological-wastewater-tr2018isa-tran-191011175840/75/Fuzzy-logic-for-plant-wide-control-of-biological-wastewater-treatment-process-including-greenhouse-gas-emissions-16-2048.jpg)

![162 I. Santín et al. / ISA Transactions 77 (2018)146–166

[System]

[Output2] Name

= ’ SO, 4 ’

Range = [0 4]

NumMFs = 6

MF1 = ’ low ’ : ’ trimf’ , [−1000000 0 0.5625]

MF2 = ’ medium − low ’ : ’ trimf’ , [0 0.5625 1.125]

MF3 = ’ medium’ : ’ trimf ’ , [0.5625 1.125 1.688]

MF4 = ’ medium−high ’ : ’ trimf’ , [1.125 1.688 2.25]

MF5 = ’ high ’ : ’ trimf’ , [1.688 2.25 2.813]

MF6 = ’ very_high ’ : ’ trimf’ , [3 3.75 1000000]

[Output3] Name

= ’ SO, 5 ’

Range = [0 2]

NumMFs = 6

MF1 = ’ low ’ : ’ trimf’ , [−1000000 0 0.3125]

MF2 = ’ medium − low ’ : ’ trimf’ , [0 0.3125 0.625]

MF3 = ’ medium’ : ’ trimf ’ , [0.3125 0.625 0.9375]

MF4 = ’ medium−high ’ : ’ trimf’ , [0.625 0.9375 1.25]

MF5 = ’ high ’ : ’ trimf’ , [0.9375 1.25 1.563]

MF6 = ’ very_high ’ : ’ trimf’ , [1.6 1.85 1000000]

[Output4]

Name = ’ Qa’

Range = [1000 124000]

NumMFs = 3

MF1 = ’ low ’ : ’ trimf’ , [−1e+15 1000 50200]

MF2 = ’ medium ’ : ’ trimf ’ , [13300 62500 111700]

MF3 = ’ high ’ : ’ trimf’ , [74800 124000 1e+15]

[Output5]

Name = ’ qEC, 1 ’

Range = [−0.5 5.5]

NumMFs = 5

MF1 = ’ low ’ : ’ trimf’ , [−1000000 −0.5 1]

MF2 = ’ medium− low ’ : ’ trimf’ , [−0.5 1 2.5]

MF3 = ’ medium’ : ’ trimf’ , [1 2.5 4]

MF4 = ’ medium−high ’ : ’ trimf’ , [2.5 4 5.5]

MF5 = ’ high ’ : ’ trimf’ , [4 5.5 1000000]

[Output6]

Name = ’ Qst ’

Range = [−50 300]

NumMFs = 5

MF1 = ’ low ’ : ’ trimf’ , [−1000000 −50 37.5]

MF2 = ’ medium− low ’ : ’ trimf’ , [−50 37.5125]

MF3 = ’ medium ’ : ’ trimf’ , [37.5 125 212.5]

MF4 = ’ medium−high ’ : ’ trimf’ , [125 212.5300]

MF5 = ’ high ’ : ’ trimf’ , [212.5300 1000000]

[Rules]

1 0 0 −3 0 0 1 −3 0 0 0 0 0 0 , 1 0 0 0 0 0 (1) : 1

2 0 0 −3 0 0 1 −3 0 0 0 0 0 0 , 2 0 0 0 0 0 (1) : 1

3 0 0 0 0 0 0 −3 0 0 0 0 0 0 , 3 0 0 0 0 0 (1) : 1

4 0 0 0 0 0 0 −3 0 0 0 0 0 0 , 4 0 0 0 0 0 (1) : 1

5 0 0 0 0 0 0 −3 0 0 0 0 0 0 , 5 0 0 0 0 0 (1) : 1

1 0 0 1 0 0 2 −3 0 0 0 0 0 0 , 1 0 0 0 0 0 (1) : 1

2 0 0 1 0 0 2 −3 0 0 0 0 0 0 , 2 0 0 0 0 0 (1) : 1

1 0 0 2 0 0 2 −3 0 0 0 0 0 0 , 3 0 0 0 0 0 (1) : 1

2 0 0 2 0 0 2 −3 0 0 0 0 0 0 , 3 0 0 0 0 0 (1) : 1

1 0 0 3 0 0 0 −3 0 0 0 0 0 0 , 3 0 0 0 0 0 (1) : 1

2 0 0 3 0 0 0 −3 0 0 0 0 0 0 , 3 0 0 0 0 0 (1) : 1

0 4 0 0 0 0 2 −3 0 0 0 0 0 0 , 0 4 0 0 0 0 (1) : 1

0 5 0 0 0 0 2 −3 0 0 0 0 0 0 , 0 5 0 0 0 0 (1) : 1

0 1 0 0 1 0 2 −3 0 0 0 0 0 0 , 0 1 0 0 0 0 (1) : 1

0 1 0 0 2 0 2 −3 0 0 0 0 0 0 , 0 1 0 0 0 0 (1) : 1

0 2 0 0 1 0 2 −3 0 0 0 0 0 0 , 0 2 0 0 0 0 (1) : 1

(continued on nextpage)

[System]

0 2 0 0 2 0 2 −3 0 0 0 0 0 0 , 0 2 0 0 0 0 (1) : 1

0 3 0 0 0 0 2 −3 0 0 0 0 0 0 , 0 3 0 0 0 0 (1) : 1

0 1 0 0 3 0 2 −3 0 0 0 0 0 0 , 0 3 0 0 0 0 (1) : 1

0 1 0 0 4 0 2 −3 0 0 0 0 0 0 , 0 3 0 0 0 0 (1) : 1

0 2 0 0 3 0 2 −3 0 0 0 0 0 0 , 0 3 0 0 0 0 (1) : 1

0 2 0 0 4 0 2 −3 0 0 0 0 0 0 , 0 3 0 0 0 0 (1) : 1

0 6 0 0 0 0 0 −3 0 0 0 0 0 0 , 0 5 0 0 0 0 (1) : 1

0 1 0 0 −4 0 1 −3 0 0 0 0 0 0 , 0 1 0 0 0 0 (1) : 1

0 2 0 0 −4 0 1 −3 0 0 0 0 0 0 , 0 1 0 0 0 0 (1) : 1

0 3 0 0 −4 0 1 −3 0 0 0 0 0 0 , 0 2 0 0 0 0 (1) : 1

0 4 0 0 0 0 1 −3 0 0 0 0 0 0 , 0 3 0 0 0 0 (1) : 1

0 5 0 0 0 0 1 −3 0 0 0 0 0 0 , 0 4 0 0 0 0 (1) : 1

0 1 0 0 4 0 1 −3 0 0 0 0 0 0 , 0 3 0 0 0 0 (1) : 1

0 2 0 0 4 0 1 −3 0 0 0 0 0 0 , 0 3 0 0 0 0 (1) : 1

0 3 0 0 4 0 1 −3 0 0 0 0 0 0 , 0 3 0 0 0 0 (1) : 1

0 0 0 0 0 0 0 3 0 0 0 0 0 0 , 6 6 6 0 0 0 (1) : 1

0 0 0 0 0 0 0 −3 5 0 0 0 0 0 , 1 1 1 0 0 0 (1) : 1

0 0 1 0 0 −1 0 −3 0 0 0 0 0 0 , 0 0 1 0 0 0 (1) : 1

0 0 2 0 0 0 2 −3 0 0 0 0 0 0 , 0 0 3 0 0 0 (1) : 1

0 0 3 0 0 0 2 −3 0 0 0 0 0 0 , 0 0 4 0 0 0 (1) : 1

0 0 4 0 0 0 2 −3 0 0 0 0 0 0 , 0 0 5 0 0 0 (1) : 1

0 0 5 0 0 0 2 −3 0 0 0 0 0 0 , 0 0 5 0 0 0 (1) : 1

0 0 6 0 0 0 0 −3 0 0 0 0 0 0 , 0 0 5 0 0 0 (1) : 1

0 0 2 0 0 −1 1 −3 0 0 0 0 0 0 , 0 0 1 0 0 0 (1) : 1

0 0 3 0 0 −1 1 −3 0 0 0 0 0 0 , 0 0 2 0 0 0 (1) : 1

0 0 4 0 0 0 1 −3 0 0 0 0 0 0 , 0 0 3 0 0 0 (1) : 1

0 0 5 0 0 0 1 −3 0 0 0 0 0 0 , 0 0 4 0 0 0 (1) : 1

0 0 1 0 0 1 0 −3 0 0 0 0 0 0 , 0 0 3 0 0 0 (1) : 1

0 0 2 0 0 1 1 −3 0 0 0 0 0 0 , 0 0 3 0 0 0 (1) : 1

0 0 3 0 0 1 1 −3 0 0 0 0 0 0 , 0 0 3 0 0 0 (1) : 1

0 0 0 0 0 0 0 1 0 1 1 0 0 0 , 0 0 0 3 0 0 (1) : 1

0 0 0 0 0 0 0 −3 0 0 −1 0 0 0 , 0 0 0 2 0 0 (1) : 1

0 0 0 0 0 0 0 3 0 0 0 0 0 0 , 0 0 0 1 0 0 (1) : 1

0 0 0 0 0 0 0 2 0 1 1 0 0 0 , 0 0 0 3 0 0 (1) : 1

0 0 0 0 0 0 0 0 1 0 −1 −3 0 0 , 0 0 0 0 1 0 (1) : 1

0 0 0 0 0 0 0 0 2 0 −1 2 0 0 , 0 0 0 0 2 0 (1) : 1

0 0 0 0 0 0 0 0 3 0 −1 2 0 0 , 0 0 0 0 3 0 (1) : 1

0 0 0 0 0 0 0 0 4 0 −1 2 0 0 , 0 0 0 0 4 0 (1) : 1

0 0 0 0 0 0 0 0 5 0 0 0 0 0 , 0 0 0 0 5 0 (1) : 1

0 0 0 0 0 0 0 0 1 0 1 −3 0 0 , 0 0 0 0 3 0 (1) : 1

0 0 0 0 0 0 0 0 2 0 1 −3 0 0 , 0 0 0 0 4 0 (1) : 1

0 0 0 0 0 0 0 0 3 0 1 −3 0 0 , 0 0 0 0 5 0 (1) : 1

0 0 0 0 0 0 0 0 4 0 1 −3 0 0 , 0 0 0 0 5 0 (1) : 1

0 0 0 0 0 0 0 0 1 0 −1 3 0 0 , 0 0 0 0 3 0 (1) : 1

0 0 0 0 0 0 0 0 2 0 −1 3 0 0 , 0 0 0 0 4 0 (1) : 1

0 0 0 0 0 0 0 0 3 0 −1 3 0 0 , 0 0 0 0 4 0 (1) : 1

0 0 0 0 0 0 0 0 4 0 −1 3 0 0 , 0 0 0 0 5 0 (1) : 1

0 0 0 0 0 0 0 0 0 0 1 3 0 0 , 0 0 0 0 5 0 (1) : 1

0 0 0 0 0 0 0 0 2 0 −1 1 0 0 , 0 0 0 0 1 0 (1) : 1

0 0 0 0 0 0 0 0 3 0 −1 1 0 0 , 0 0 0 0 2 0 (1) : 1

0 0 0 0 0 0 0 0 4 0 −1 1 0 0 , 0 0 0 0 3 0 (1) : 1

0 0 0 0 0 0 0 0 0 0 0 0 1 2 , 0 0 0 0 0 5 (1 ): 1

0 0 0 0 0 0 0 0 0 0 0 0 2 2 , 0 0 0 0 0 4 (1 ): 1

0 0 0 0 0 0 0 0 0 0 0 0 3 2 , 0 0 0 0 0 3 (1 ): 1

0 0 0 0 0 0 0 0 0 0 0 0 4 2 , 0 0 0 0 0 2 (1 ): 1

0 0 0 0 0 0 0 0 0 0 0 0 5 0 , 0 0 0 0 0 1 (1 ): 1

0 0 0 0 0 0 0 0 0 0 0 0 1 3 , 0 0 0 0 0 3 (1 ): 1

0 0 0 0 0 0 0 0 0 0 0 0 2 3 , 0 0 0 0 0 3 (1 ): 1

0 0 0 0 0 0 0 0 0 0 0 0 3 3 , 0 0 0 0 0 2 (1 ): 1

0 0 0 0 0 0 0 0 0 0 0 0 4 3 , 0 0 0 0 0 1 (1 ): 1

0 0 0 0 0 0 0 0 0 0 0 0 1 1 , 0 0 0 0 0 5 (1 ): 1

0 0 0 0 0 0 0 0 0 0 0 0 2 1 , 0 0 0 0 0 5 (1 ): 1

0 0 0 0 0 0 0 0 0 0 0 0 3 1 , 0 0 0 0 0 4 (1 ): 1

0 0 0 0 0 0 0 0 0 0 0 0 4 1 , 0 0 0 0 0 3 (1 ): 1](https://image.slidesharecdn.com/fuzzy-logic-for-plant-wide-control-of-biological-wastewater-tr2018isa-tran-191011175840/75/Fuzzy-logic-for-plant-wide-control-of-biological-wastewater-treatment-process-including-greenhouse-gas-emissions-17-2048.jpg)

![I. Santín et al. / ISA Transactions 77 (2018)146–166 165

References

[1] Vilanova R, Santín I, Pedret C. Control y operacin de estaciones depuradoras de

aguas residuales: modelado y simulacin. Revista Iberoamericana de Automtica e

Informtica industrial 2017;14:217–33.

[2] Vilanova R, Santín I, Pedret C. Control en estaciones depuradoras de aguas

residuales: estado actual y perspectivas. Revista Iberoamericana de Automtica

e Informtica industrial 2017;14:329–45.

[3] Kimochi Y, Inamori Y, Mizuochi M, Xu K-Q, Matsumura M. Nitrogen removal

and N2 O emission in a full-scale domestic wastewater treatment plant with

intermittent aeration. J Ferment Bioeng 1998;86(2):202–6.

[4] Kampschreur MJ, Temmink H, Kleerebezem R, Jetten MS, van Loosdrecht

MC. Nitrous oxide emission during wastewater treatment. Water Res

2009;43:4093–103.

[5] Foley J, Yuan Z, Keller J, Senante E, Chandran K, Willis J, Shah A, van Loosdrecht

MCM, van Voorthuizen E. N2 O and CH4 emission from wastewater collection and

treatment systems, Scientific and Technical Report No.30. London, UK: Global

Water Research Coalition; 2011.

[6] Law Y, Ni B, Lant P,Yuan Z.Nitrous oxide(N2 O)production by an enriched culture

of ammonia oxidising bacteria depends on its ammonia oxidation rate. Water Res

2012;46:3409–19.

[7] Flores-Alsina X, Corominas L, Snip L, Vanrolleghem PA. Including greenhouse

gas emissions during benchmarking of wastewater treatment plant control

strategies. Water Res 2011;45(16):4700–10.

[8] Flores-Alsina X, Arnell M, Amerlinck Y, Corominas L, Gernaey KV, Guo L,

Lindblom E, Nopens I, Porro J, Shaw A, Snip L, Vanrolleghem PA, Jeppsson U.

Balancing effl uent quality, economic cost and greenhouse gas emissions during

the evaluation of(plant-wide) control/operational strategies in WWTPs.Sci Total

Environ 2014;466–467:616–24.

[9] Aboobakar A, Cartmell E, Stephenson T, Jones M, Vale P, Dotro G. Nitrous oxide

emissions and dissolved oxygen profiling in a full-scale nitrifying activated

sludge treatment plant. Water Res 2013;47(2):524–34.

[10] Wang Y, Lin X, Zhou D, Ye L, Han H, Song C. Nitric oxide and nitrous oxide

emissions from a full-scale activated sludge anaerobic/anoxic/oxic process. Chem

Eng J 2016;289:330–40.](https://image.slidesharecdn.com/fuzzy-logic-for-plant-wide-control-of-biological-wastewater-tr2018isa-tran-191011175840/75/Fuzzy-logic-for-plant-wide-control-of-biological-wastewater-treatment-process-including-greenhouse-gas-emissions-20-2048.jpg)

![166 I. Santín et al. / ISA Transactions 77 (2018)146–166

[11] Monteith HD, Sahely HR, MacLean HL, Bagley DM. A rational procedure for

estimation of greenhouse-gas emissions from municipal wastewater treatment

plants. Water Environ Res 2005;77:390–403.

[12] Guo L, VanrolleghemPA. Calibration and validation ofan activated sludge model

for greenhouse gases no. 1 (ASMG1): prediction of temperature-dependent N2 O

emission dynamics. Bioproc Biosyst Eng 2014;37:151.

[13] Copp JB. The cost simulation benchmark: description and simulator manual

(COST action 624 and action 682). Luxembourg: Offi ce for Offi cial Publications

od the European Union; 2002.

[14] Gernaey K, Jeppsson U, Vanrolleghem P, Copp J. Benchmarking of control

strategies for wastewater treatment plants, scientific and technical report No.23.

London, UK: IWA Publishing; 2014.

[15] Mannina G, Ekama G, Caniani D, Cosenza A, Esposito G,Gori R, Garrido-Baserba

M, Rosso D, Olsson G. Greenhouse gases from wastewater treatment - a review

of modelling tools. Sci Total Environ 2016;551:254–70.

[16] Ni B-J, Yuan Z. Recent advances in mathematical modeling of nitrous oxides

emissions from wastewater treatment processes. Water Res 2015;87:336–46.

[17] BelchiorCAC,Araújo RAM,Landeck JAC.Dissolved oxygen control oftheactivated

sludge wastewater treatment process using stable adaptive fuzzy control.

Comput Chem Eng 2012;37:152–62.

[18] Nasr M, Moustafa M, Seif H, El-Kobrosy G. Application offuzzy logic control for

benchmark simulation model. 1. Sustain Environ Res 2014;24.

[19] Traore A, Grieu S, Puig S, Corominas L, Thiéry F, Polit M, Colprim J. Fuzzy

control of dissolved oxygen in a sequencing batch reactor pilot plant. Chem Eng

J 2005;111:13–9.

[20] Santín I, Pedret C, Vilanova R. Applying variable dissolved oxygen set point in

a two level hierarchical control structure to a wastewater treatment process. J

Process Control 2015;28:40–55.

[21] Meyer U, Pöpel H. Fuzzy-control for improved nitrogen removal and energy

saving in wwt-plants with pre-denitrification. Water Sci Technol 2003;47:

69–76.

[22] Pai T, Wan T, Hsu S, Chang T,Tsai Y,Lin C,Su H,Yu L.Using fuzzy inferencesystem

to improve neural network for predicting hospital wastewater treatment plant

effl uent. Comput Chem Eng 2009;33:1272–8.

[23] Santín I, Pedret C, Vilanova R. Fuzzy control and model predictive control

configurations for effl uent violations removal in wastewater treatment plants.

Ind Eng Chem Res 2015;54(10):2763–75.

[24] Santín I, Pedret C, Vilanova R, Meneses M. Advanced decision control systemfor

effl uent violations removal in wastewater treatment plants. Control Eng Pract

2016;279:207–19.

[25] Kalavrouziotis I, Pedrero F, Skarlatos D. Water and wastewater quality

assessment based on fuzzy modeling for the irrigation of Mandarin. Desalination

Water Treat 2016;57:20159–68.

[26] Hirsch P, Piotrowski R, Duzinkiewicz K, Grochowski M. Supervisory control

system for adaptive phase and work cycle management of sequencing

wastewater treatment plant. Stud Inf Control 2016;25:153–62.

[27] Barbu M, Vilanova R, Meneses M, Santin I. On the evaluation of the global

impact of control strategies applied to wastewater treatment plants. J Clean Prod

2017;149:396–405.

[28] Santín I, Barbu M, Pedret C, Vilanova R. Control strategies for nitrous oxide

emissions reduction on wastewater treatment plants operation. Water Res

2017;125:466–77.

[29] Boiocchi R, Gernaey KV, Sin G. Understanding N2 O formation mechanisms

through sensitivity analyses using a plant-wide benchmark simulation model.

Chem Eng J 2017;317:935–51.

[30] Henze M, Grady C, Gujer W, Marais G, Matsuo T. Activated sludge model 1,

scientific and technical report No.1. London, UK: IAWQ; 1987.

[31] Hiatt W, Grady JC. An updated process model for carbon oxidation, nitrification,

and denitrification. Water Environ Res 2008;80(11):2145–56.

[32] Mampaey KE, Beuckels B, Kampschreur RKMJ, van Loosdrecht MC, Volcke EI.

Modelling nitrous and nitric oxide emissions by autotrophic ammonia-oxidizing

bacteria. Environ Technol 2013;34(12):1555–66.

[33] Nopens I, Benedetti L, Jeppsson U, Pons M-N, Alex J, Copp JB, Gernaey KV,

Rosen C, Steyer J-P, Vanrolleghem PA. Benchmark Simulation Model No 2:

finalisation of plant layout and default control strategy. Water Sci Technol

2010;62(9):1967–74.

[34] KlirG, Yuan B. Fuzzy sets and fuzzy logic,vol.4.New Jersey: PrenticeHall; 1995.

[35] Mamdani E. Application offuzzy algorithms for control ofsimple dynamic plant.

Proc Inst Electr Eng 1976;121(12):1585–8.

[36] Vrecko D, Hvala N, Stare A, Burica O, Strazar M, Levstek M, Cerar P, Podbevsek

S. Improvement of ammonia removal in activated sludge process with feedfor-

ward-feedback aeration controllers.Water Sci Technol 2006;53(4–5):125–32.

[37] Stare A, Vrecko D, Hvala N, Strmcnick S. Comparison of control strategies for

nitrogen removal in an activated sludge process in terms of operating costs: a

simulation study. Water Res 2007;41(9):2004–14.

[38] Boiocchi R, Gernaey KV, Sin G.Control ofwastewater n 2 o emissions by balancing

the microbial communities using a fuzzy-logic approach. IFAC-PapersOnLine

2016;49:1157–62.](https://image.slidesharecdn.com/fuzzy-logic-for-plant-wide-control-of-biological-wastewater-tr2018isa-tran-191011175840/75/Fuzzy-logic-for-plant-wide-control-of-biological-wastewater-treatment-process-including-greenhouse-gas-emissions-21-2048.jpg)