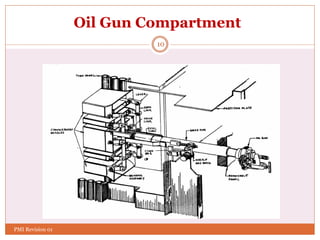

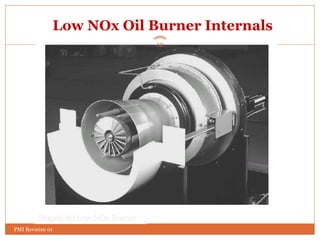

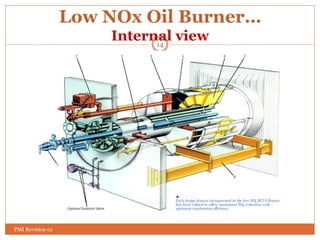

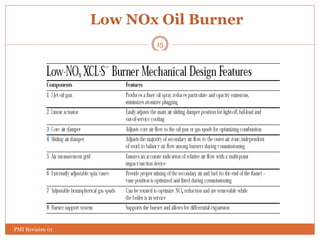

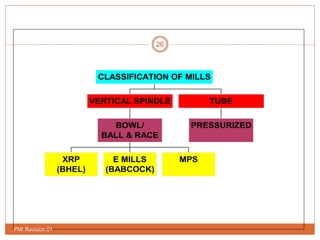

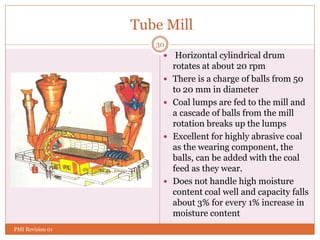

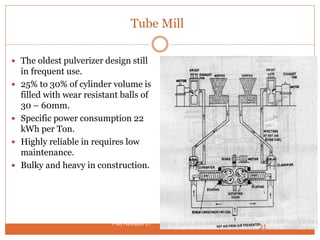

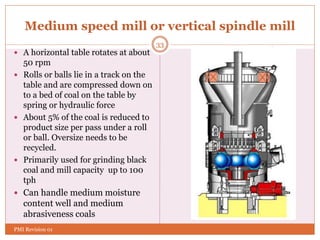

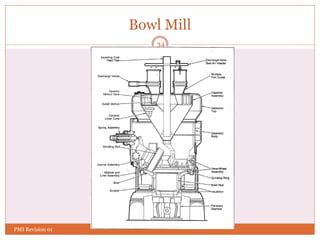

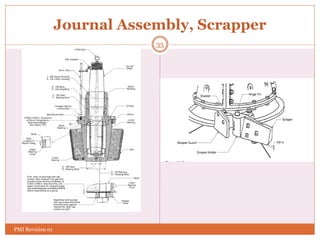

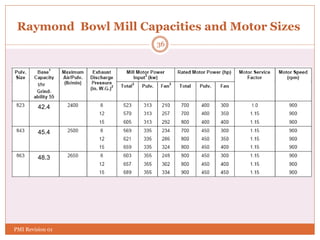

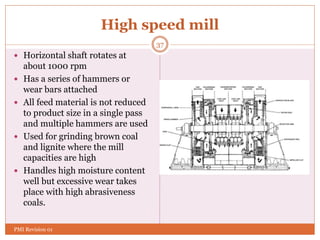

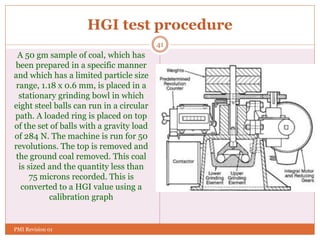

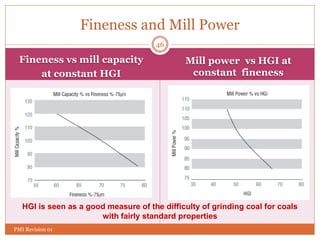

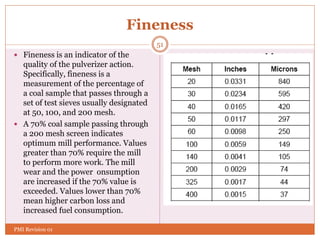

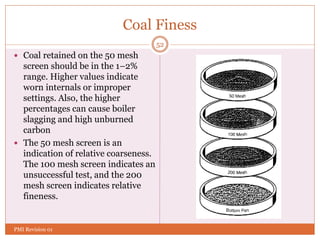

The document discusses the fuel firing system for boilers. It describes the fuel oil system and its components like fuel oil pumps, oil heaters, and filters. It also discusses atomization and different types of oil burners. Coal pulverizers like tube mills, bowl mills, and impact mills are described along with their components and operating principles. The importance of grindability index (HGI) in determining pulverizer performance is highlighted. Fineness is also discussed as a measure of pulverizer performance.