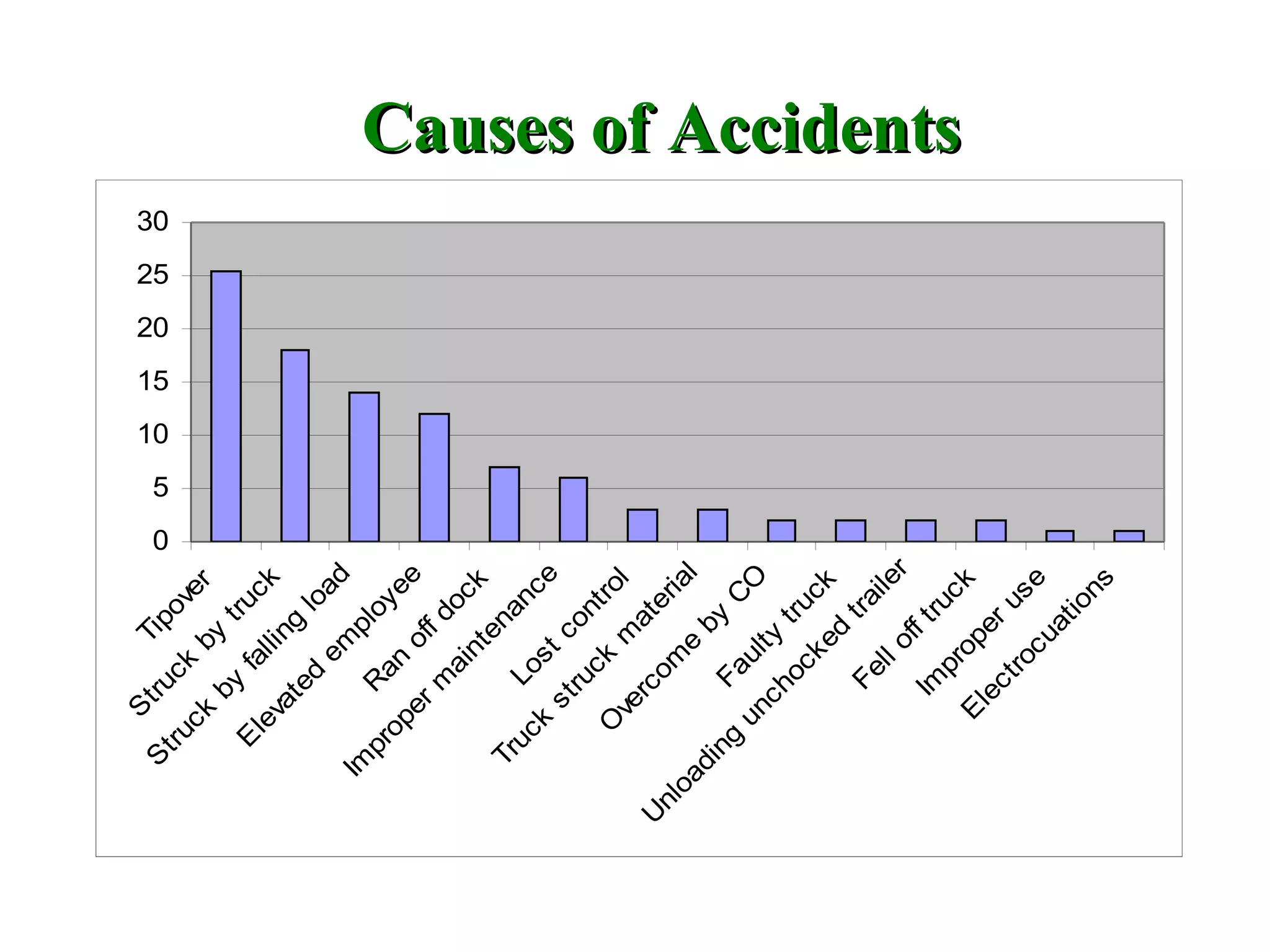

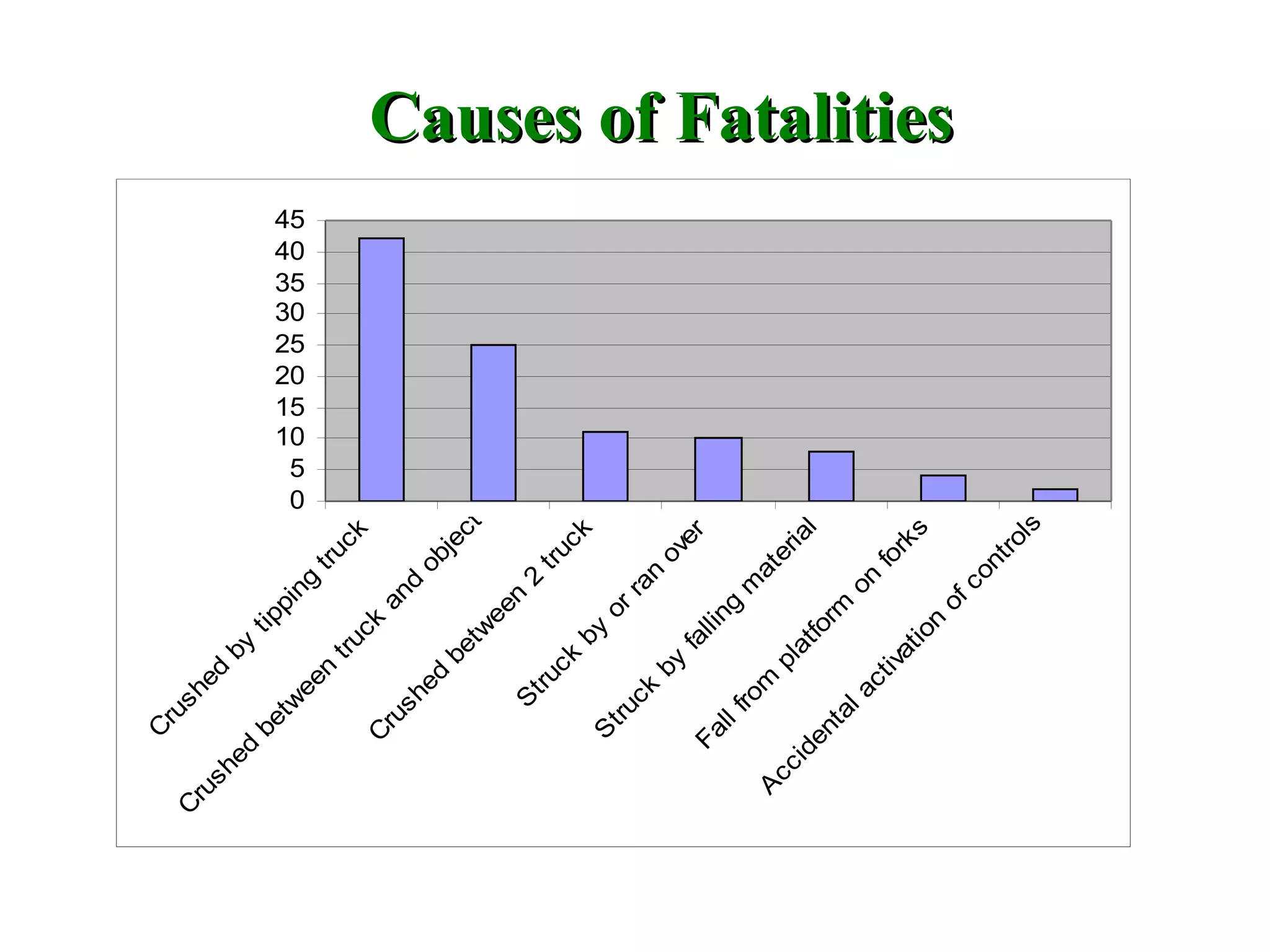

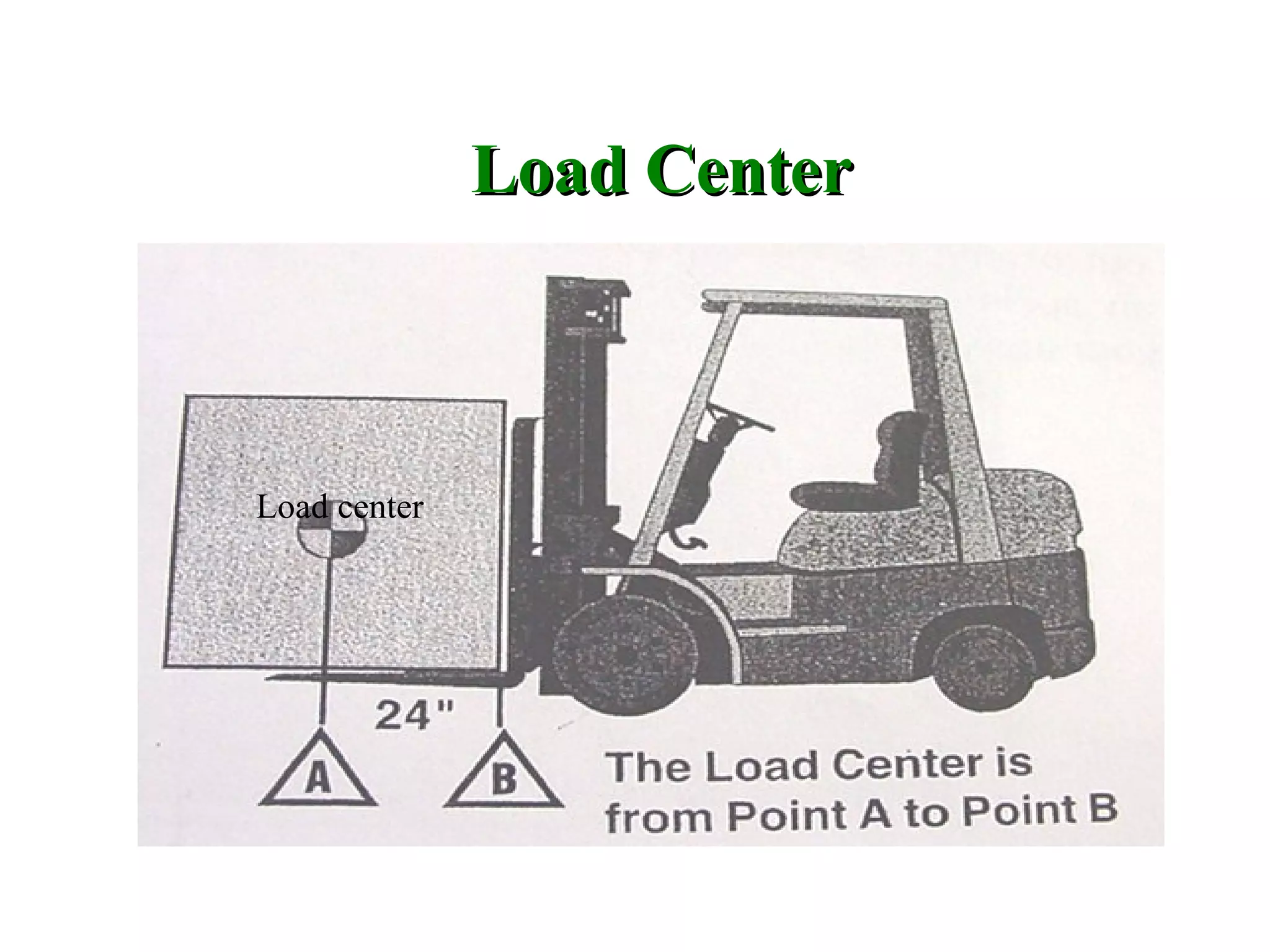

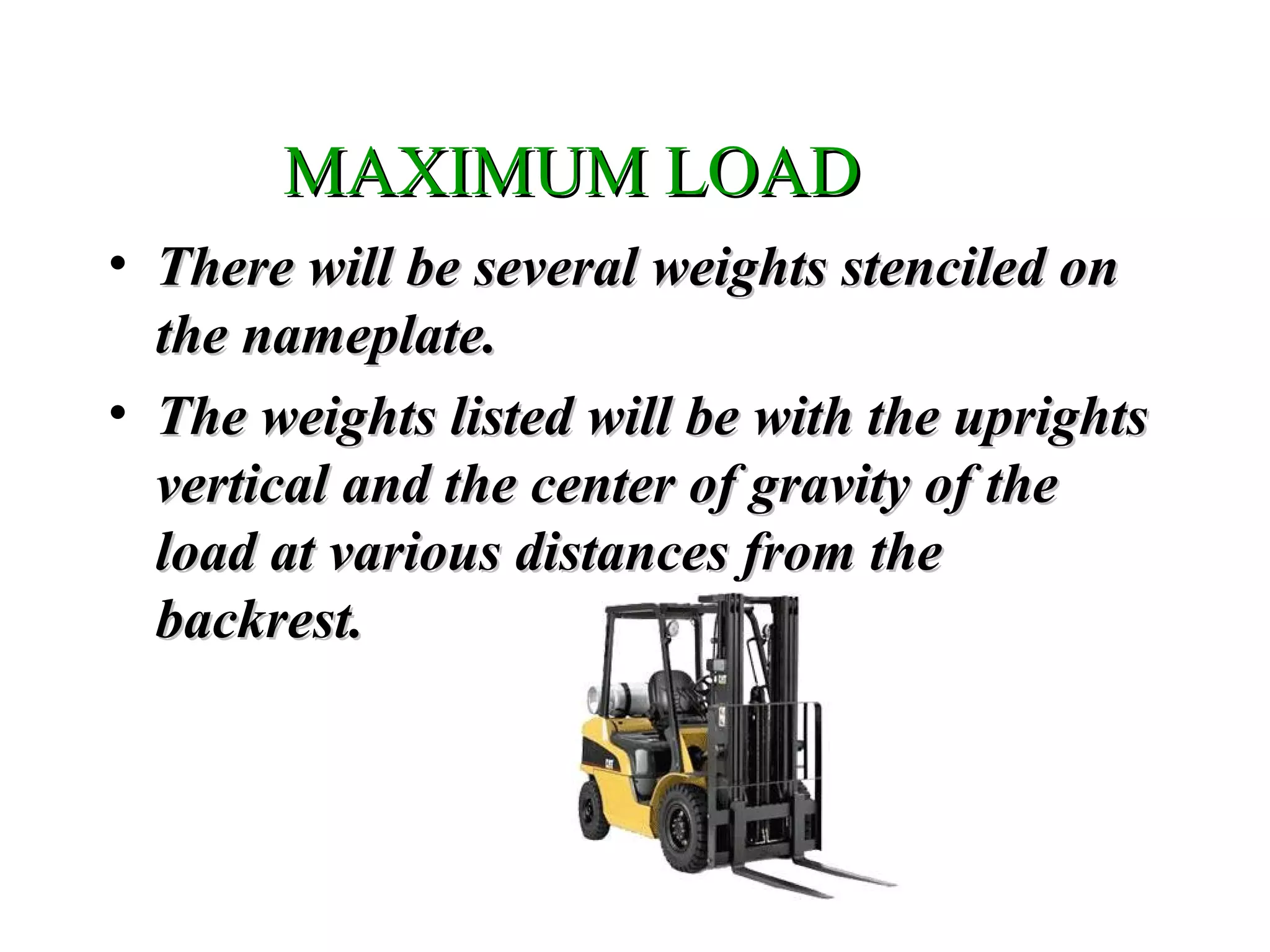

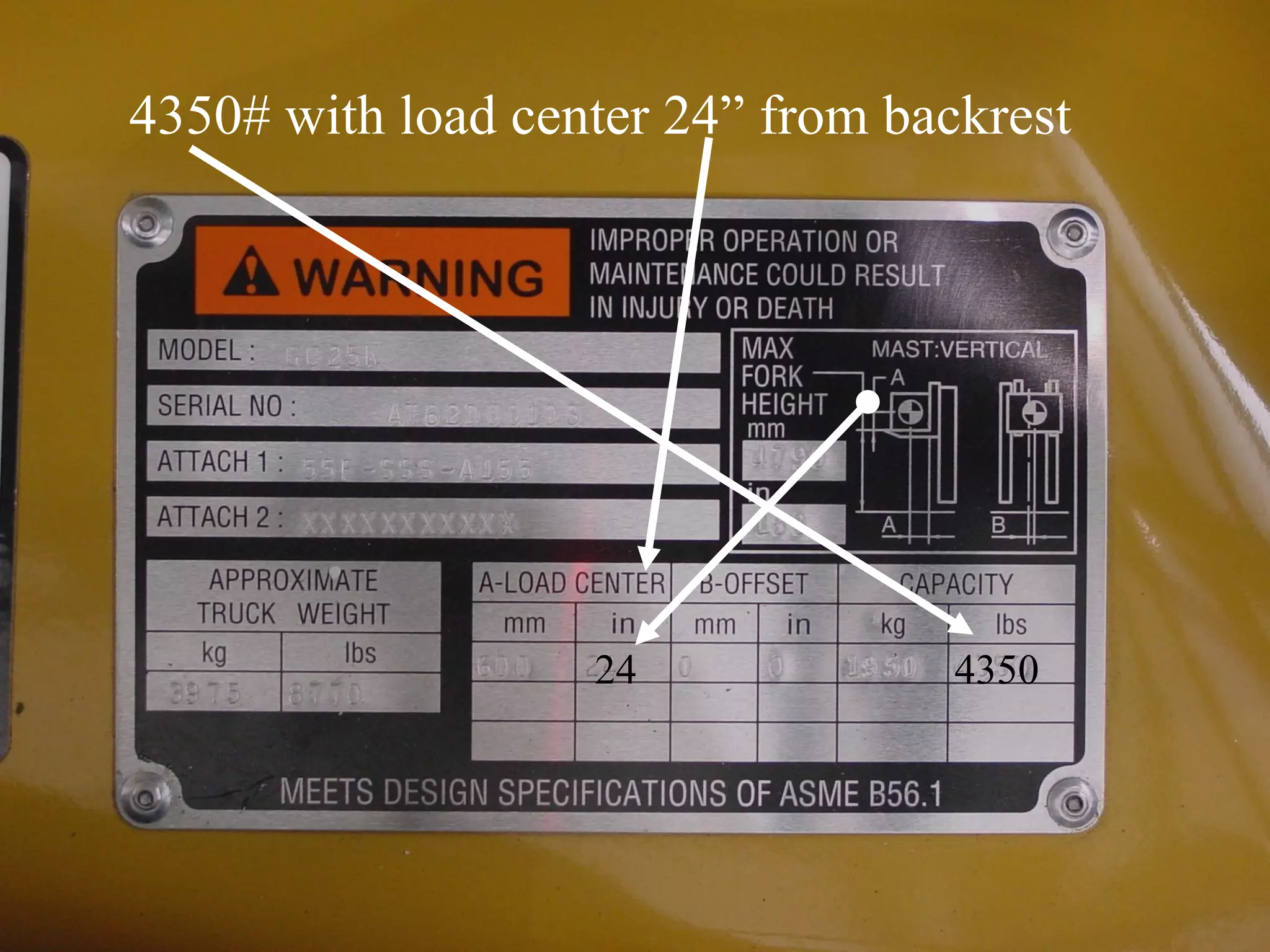

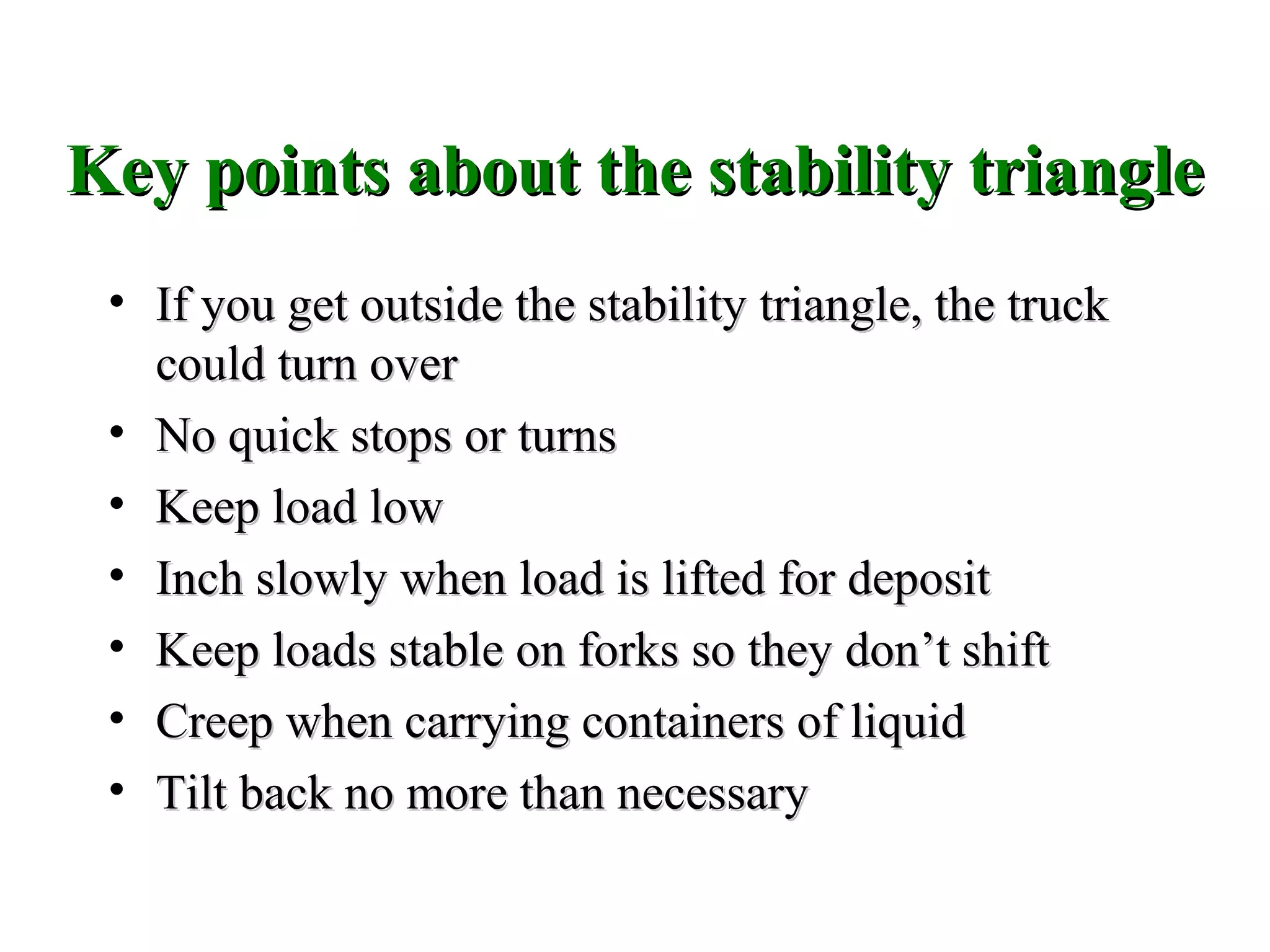

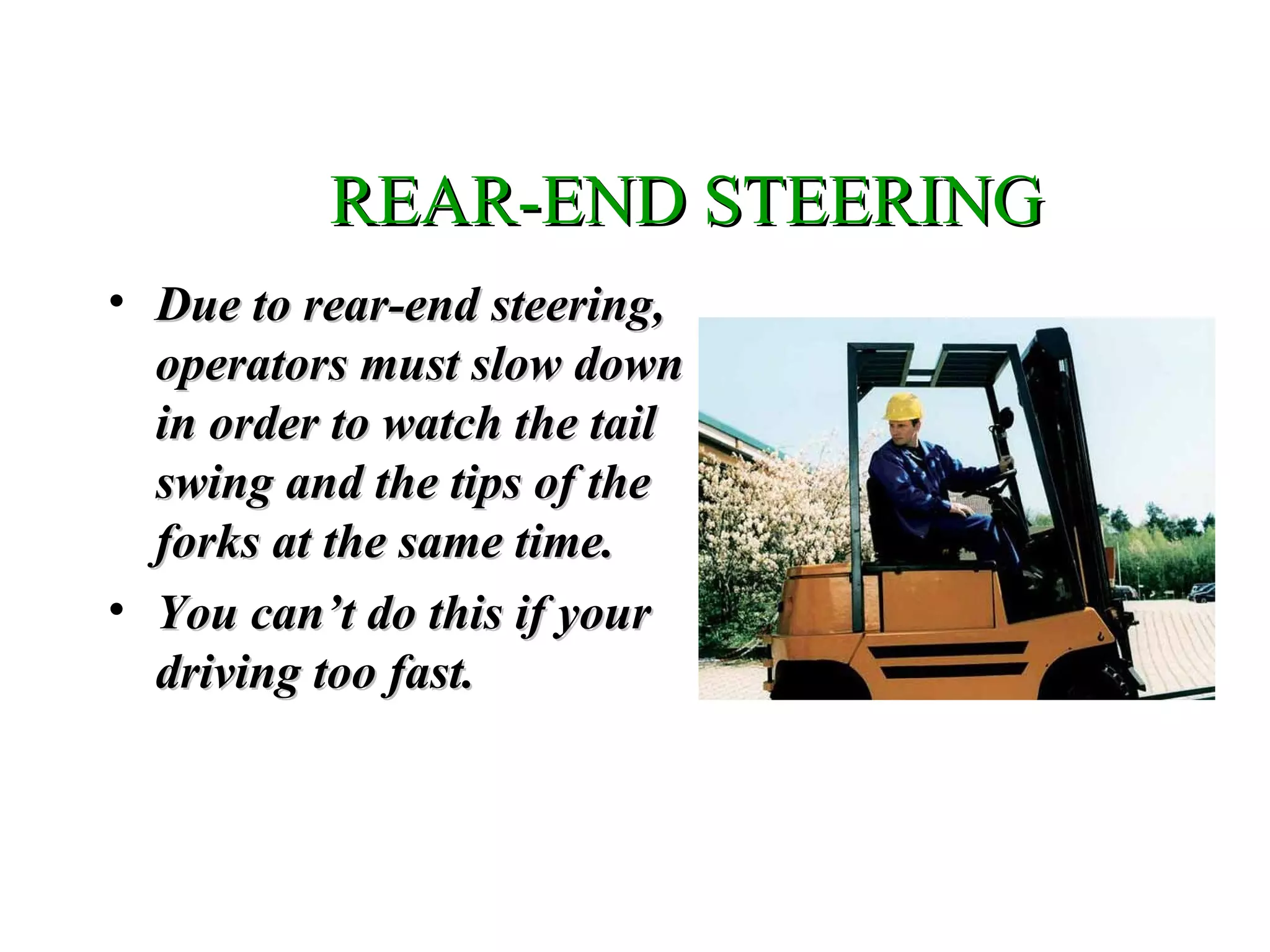

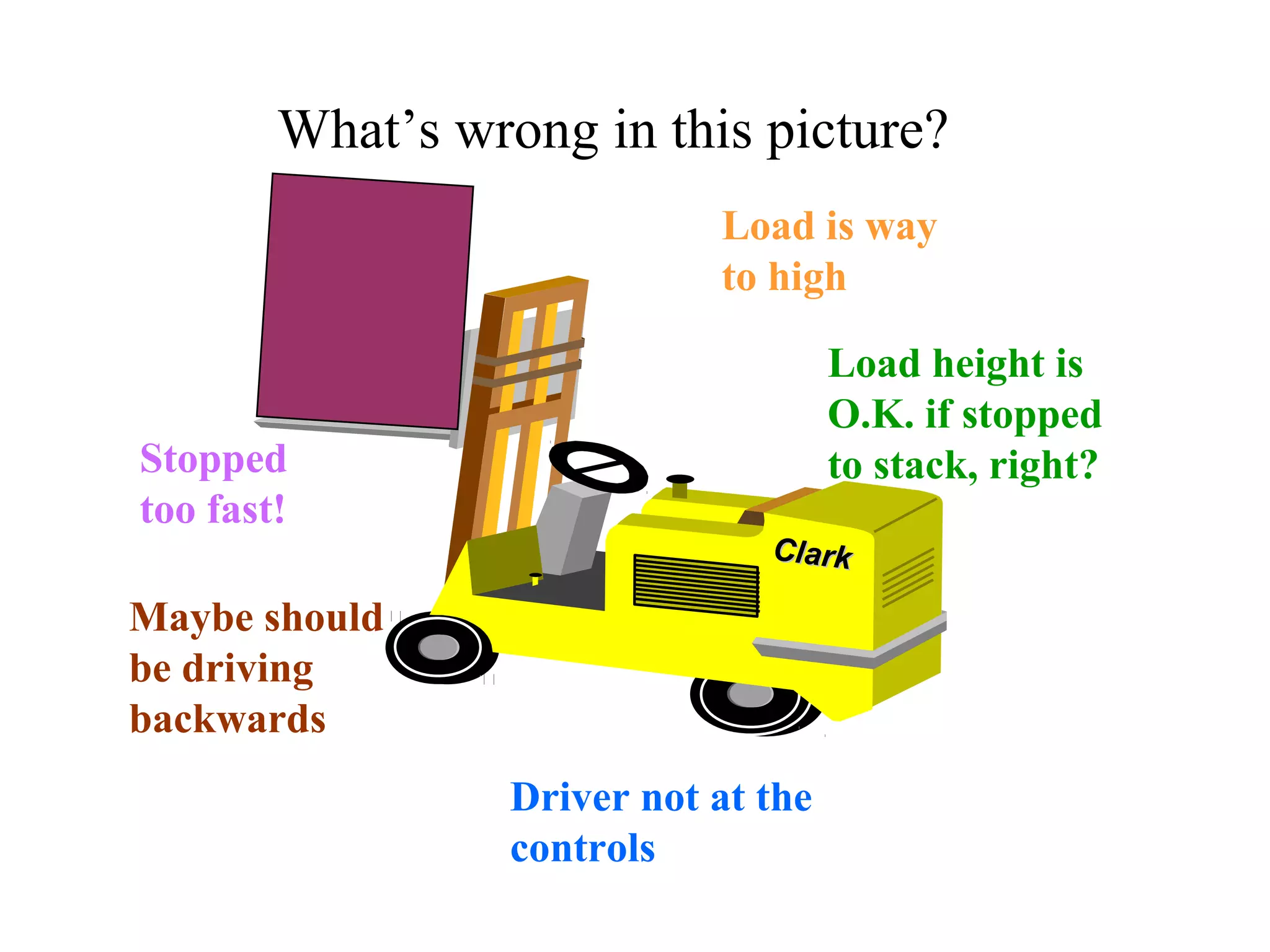

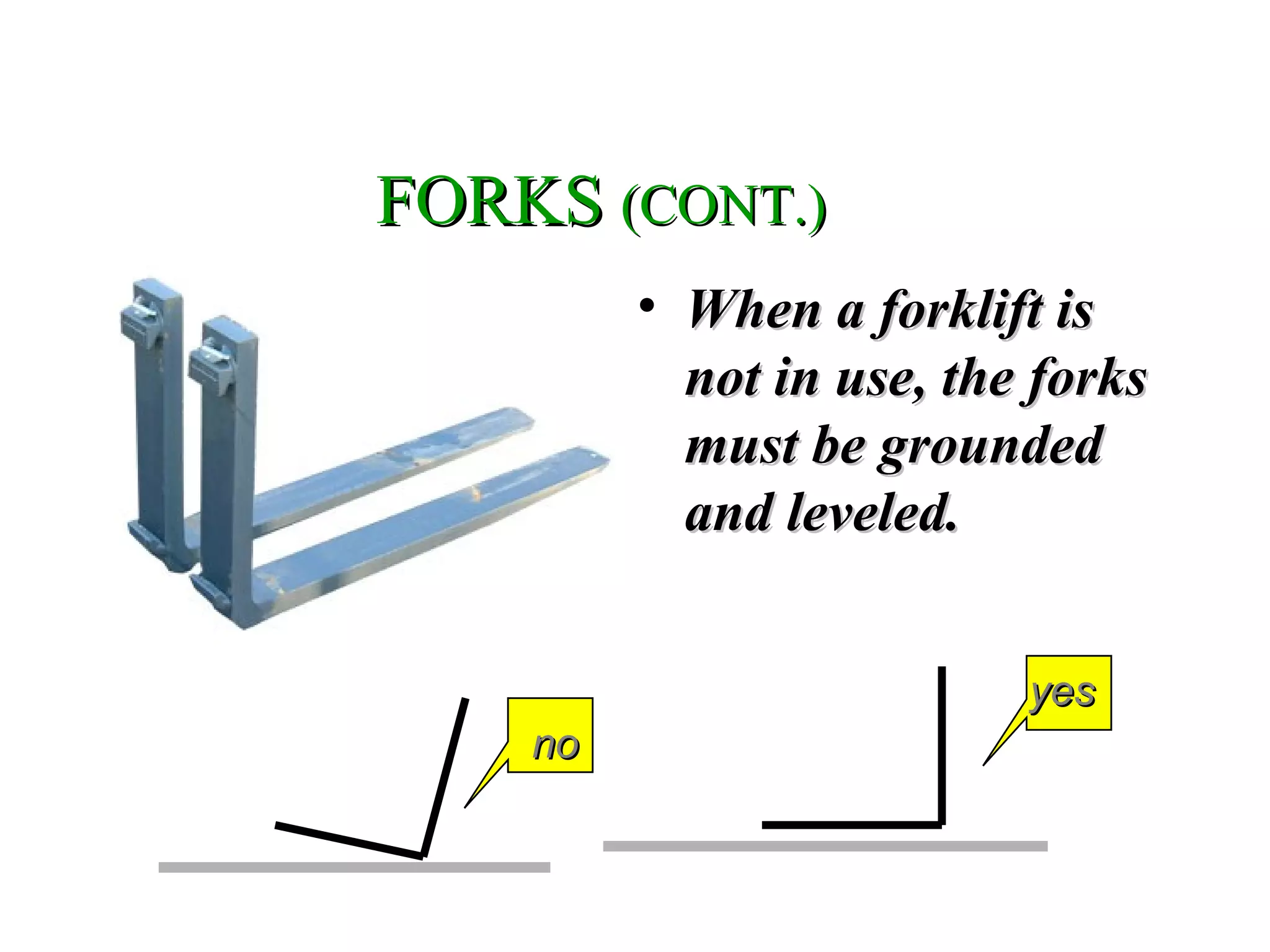

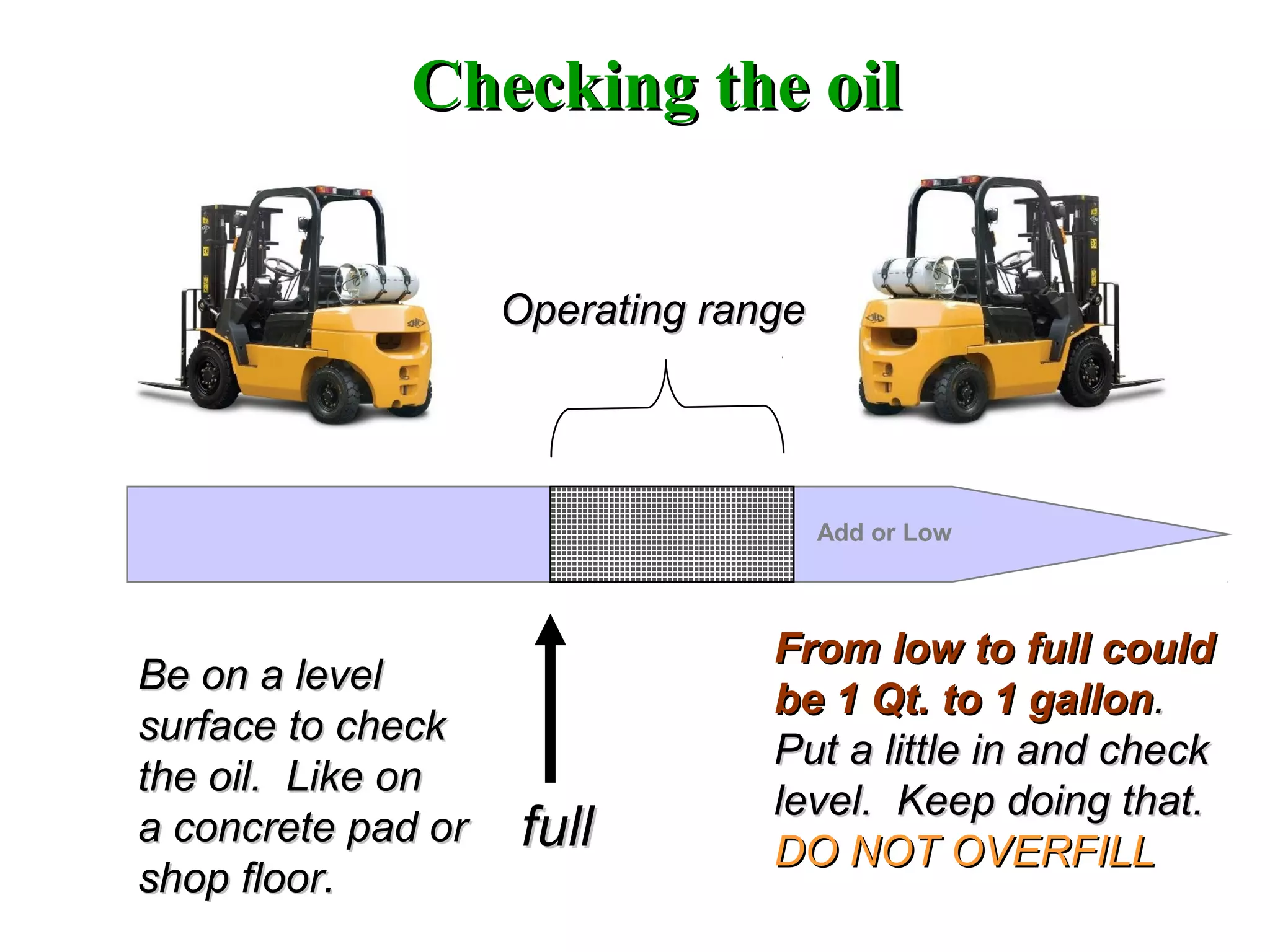

This document provides training on safe forklift operation. It outlines the objectives of the training program which are to qualify operators, teach safe operating rules, and prevent accidents and high maintenance costs. It covers causes of accidents and fatalities, the qualification program requirements, operating rules including inspections, load handling, travel, and unattended equipment. Trainees learn how to identify potential hazards and properly operate and maintain forklifts.