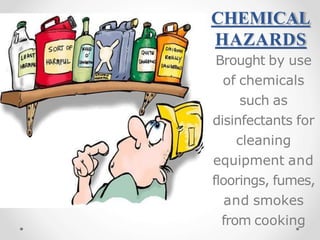

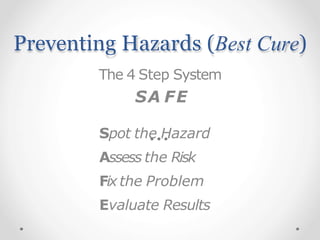

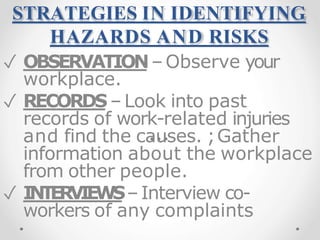

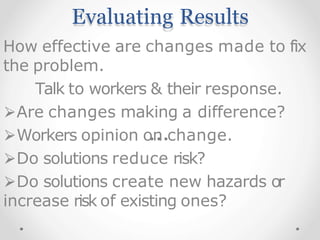

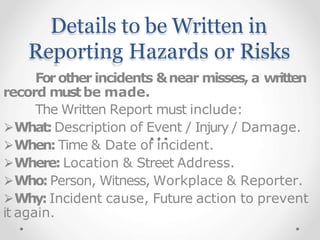

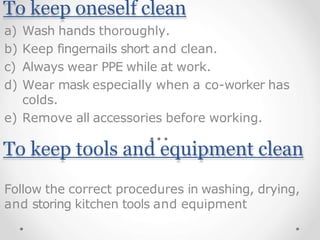

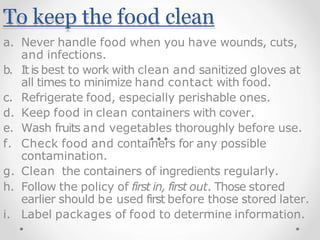

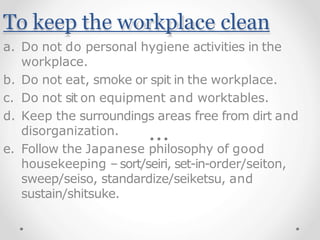

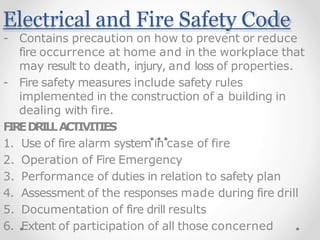

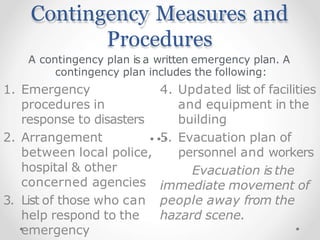

Occupational health and safety in the kitchen is important to protect workers from physical, biological, ergonomic, psychological, and chemical hazards. It aims to anticipate, recognize, evaluate, control and prevent workplace hazards that can cause injury or illness. The document outlines various hazards found in kitchens and strategies for identifying and controlling risks, including proper hygiene practices, cleaning procedures, safety regulations, and contingency planning to deal with emergencies.