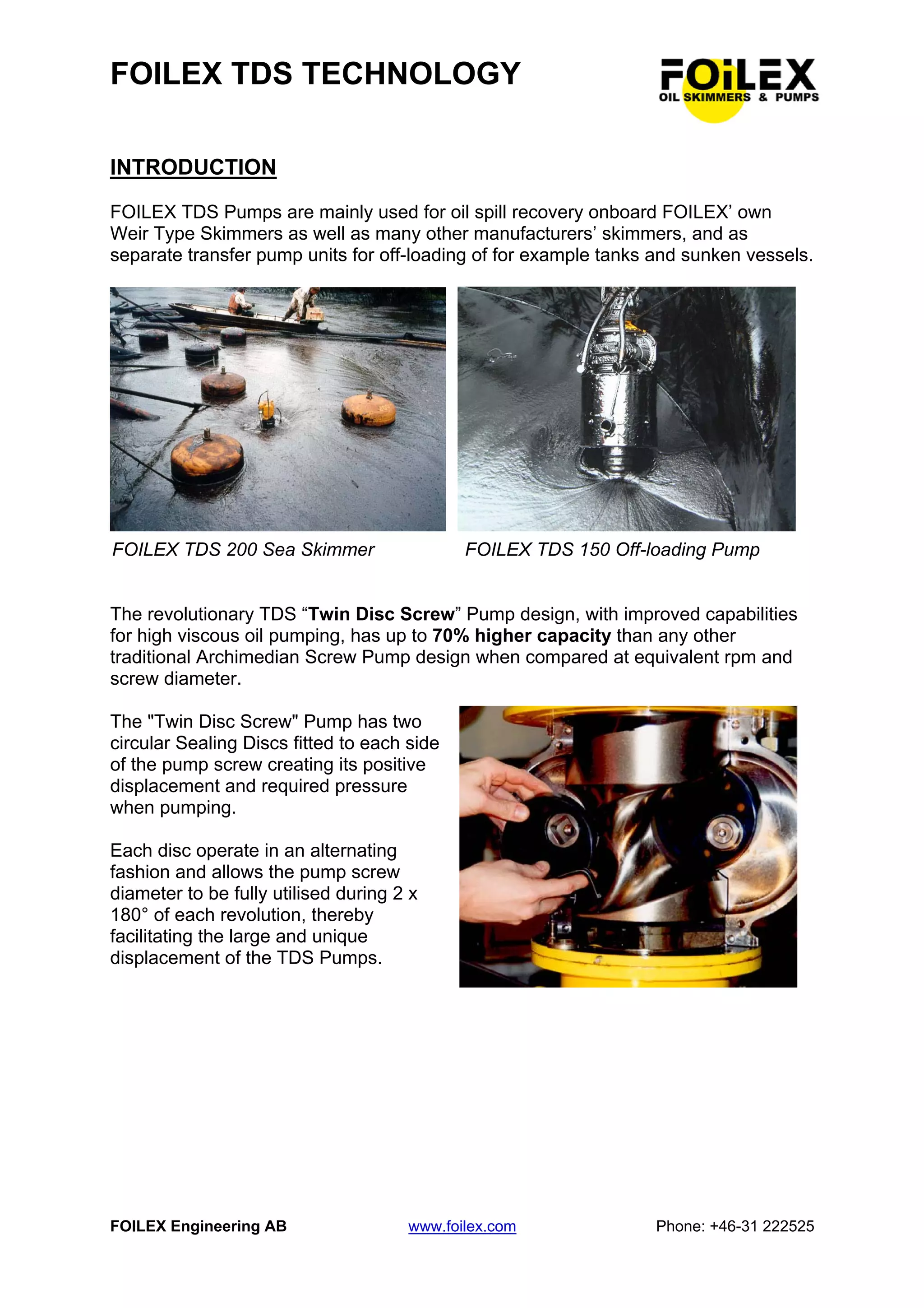

The document describes FOILEX TDS pumps, which are positive displacement pumps used for oil spill recovery and off-loading tanks. The TDS pump has a unique "Twin Disc Screw" design that provides 70% higher capacity than traditional screw pumps. Key features include a large displacement and exposed pump screw area for handling viscous oils, small outer dimensions, replaceable sealing discs, and exchangeable large discharge connections to reduce pressure drop.