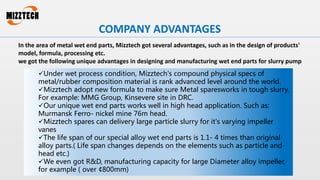

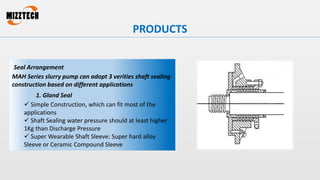

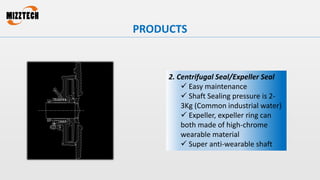

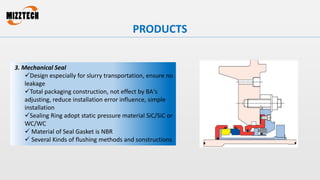

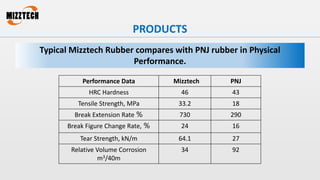

Mizztech is a privately owned Chinese company established in 2008 that manufactures mining equipment such as pumps, mills, screens, and hydrocyclones. The company has a production capacity of 1000 sets/4000 tons per year and supplies products domestically and internationally for mining, metallurgy, power, petrochemical, and other industries. Mizztech's key product is its MAH series mining slurry pump, which is interchangeable with Weir Warman pumps and uses proprietary rubber and metal composite materials for its wet end parts.