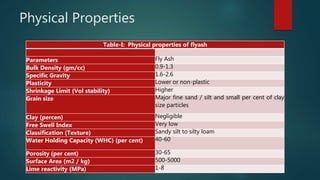

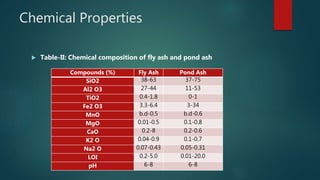

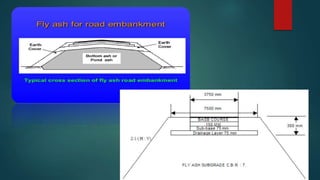

Fly ash is a byproduct of coal combustion in thermal power plants. Huge quantities of fly ash are generated and can be used beneficially in road construction. Fly ash has physical and chemical properties making it suitable for use in embankments and as a stabilizer in subgrades and bases. When used in embankments, fly ash must be compacted properly and protected with an earthen cover to prevent erosion. Engineering tests are required to evaluate the properties of fly ash before using it in road construction. National highway authorities are increasingly using fly ash to reduce costs and promote sustainable construction practices.