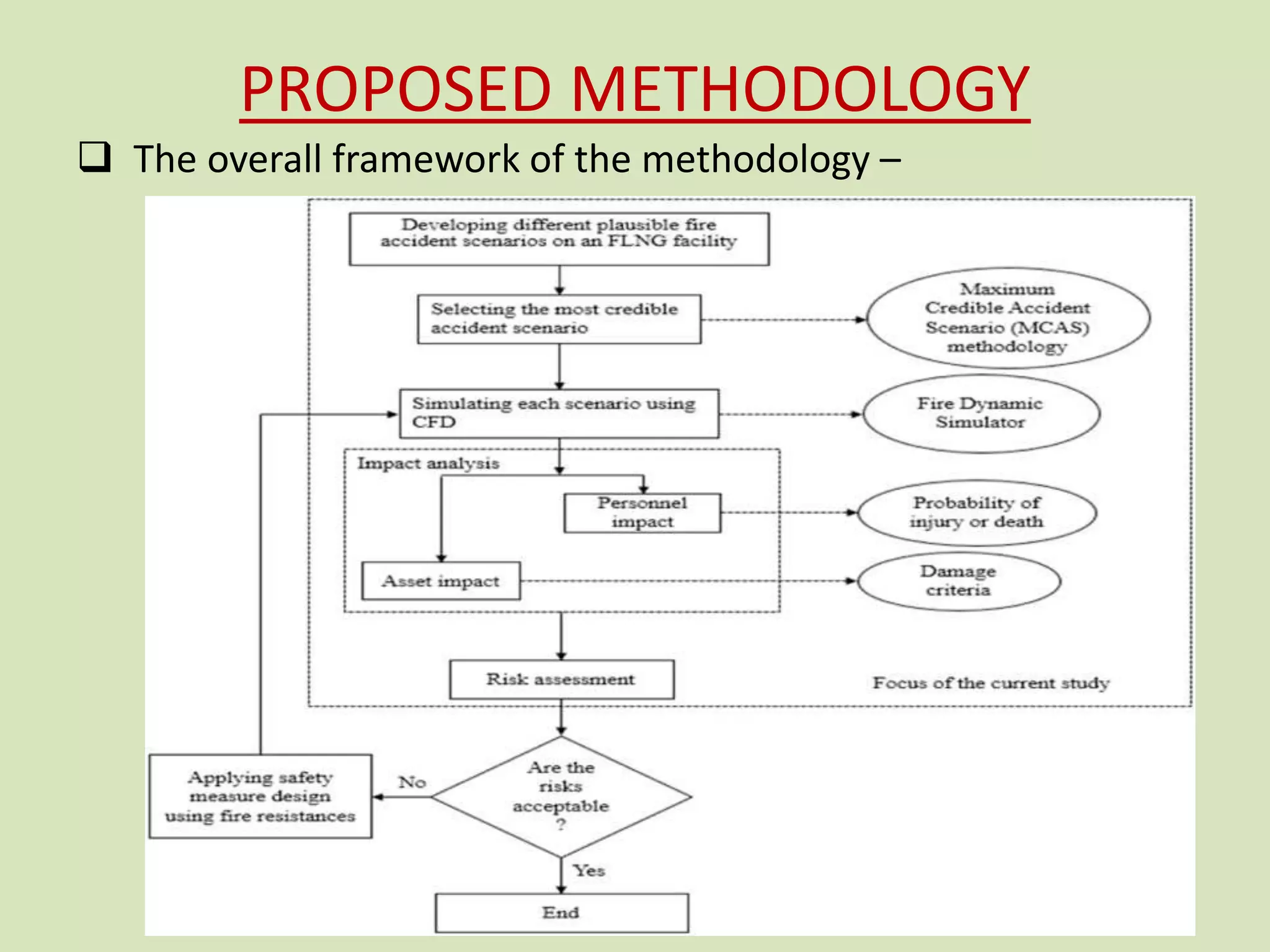

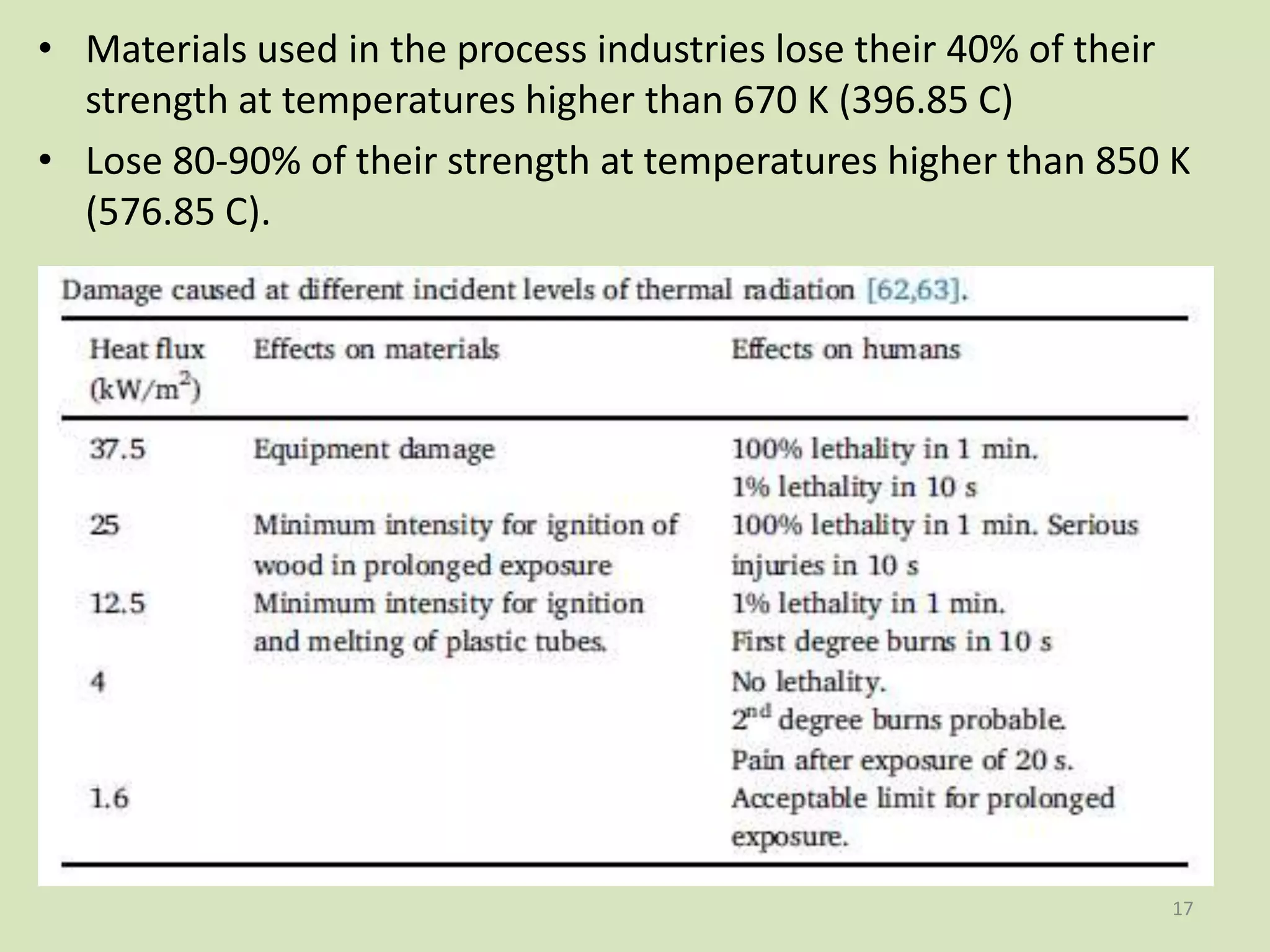

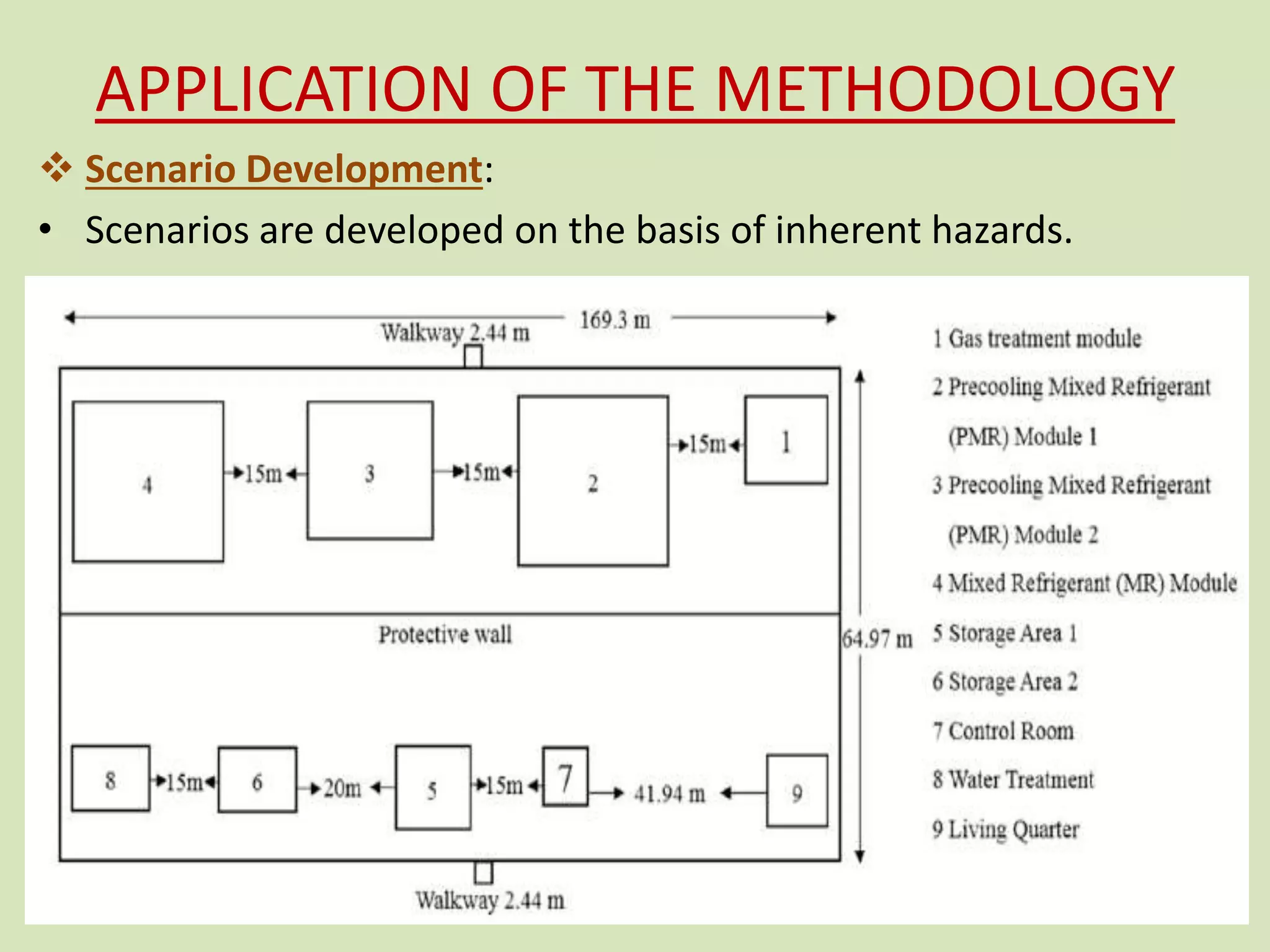

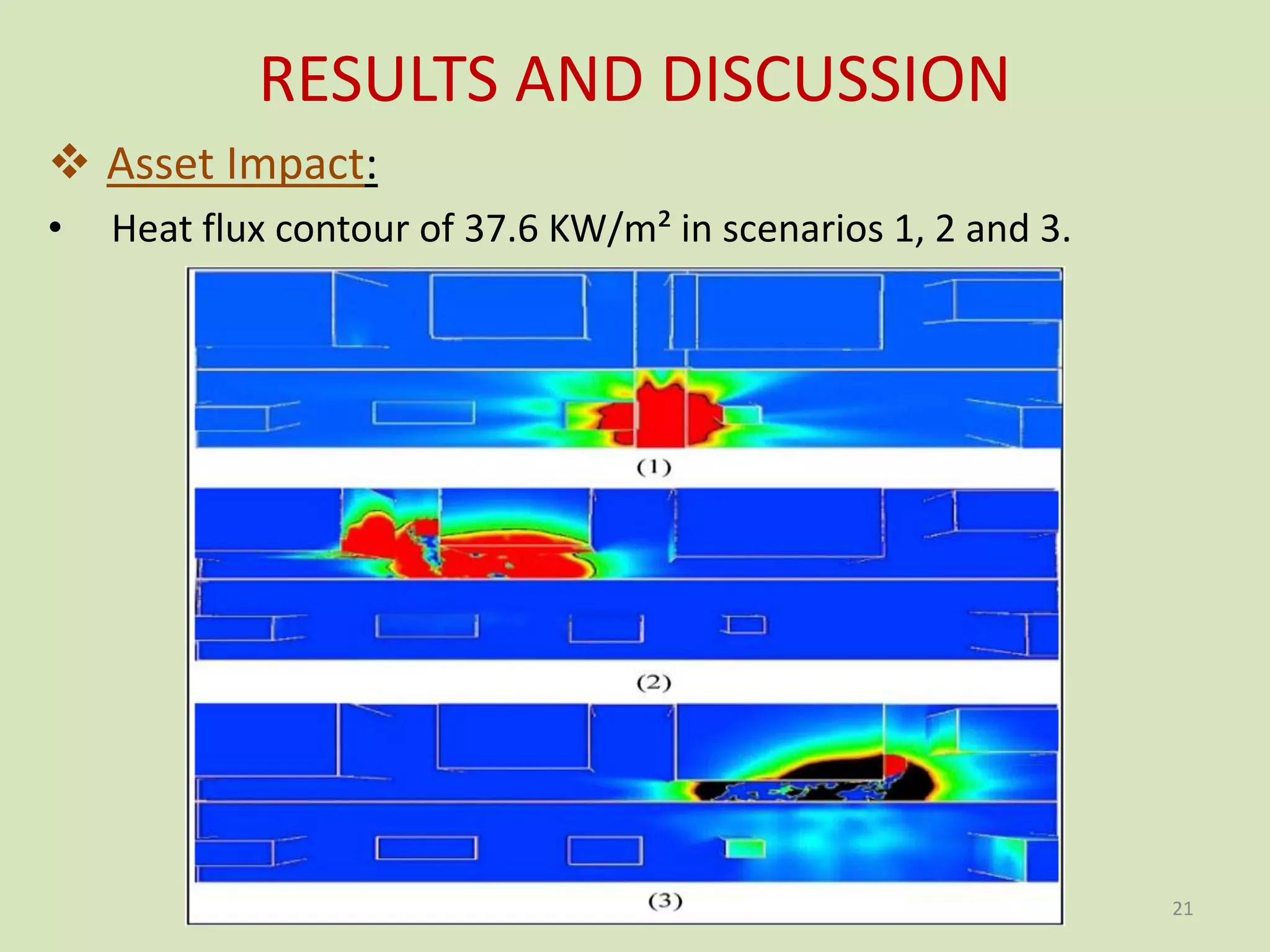

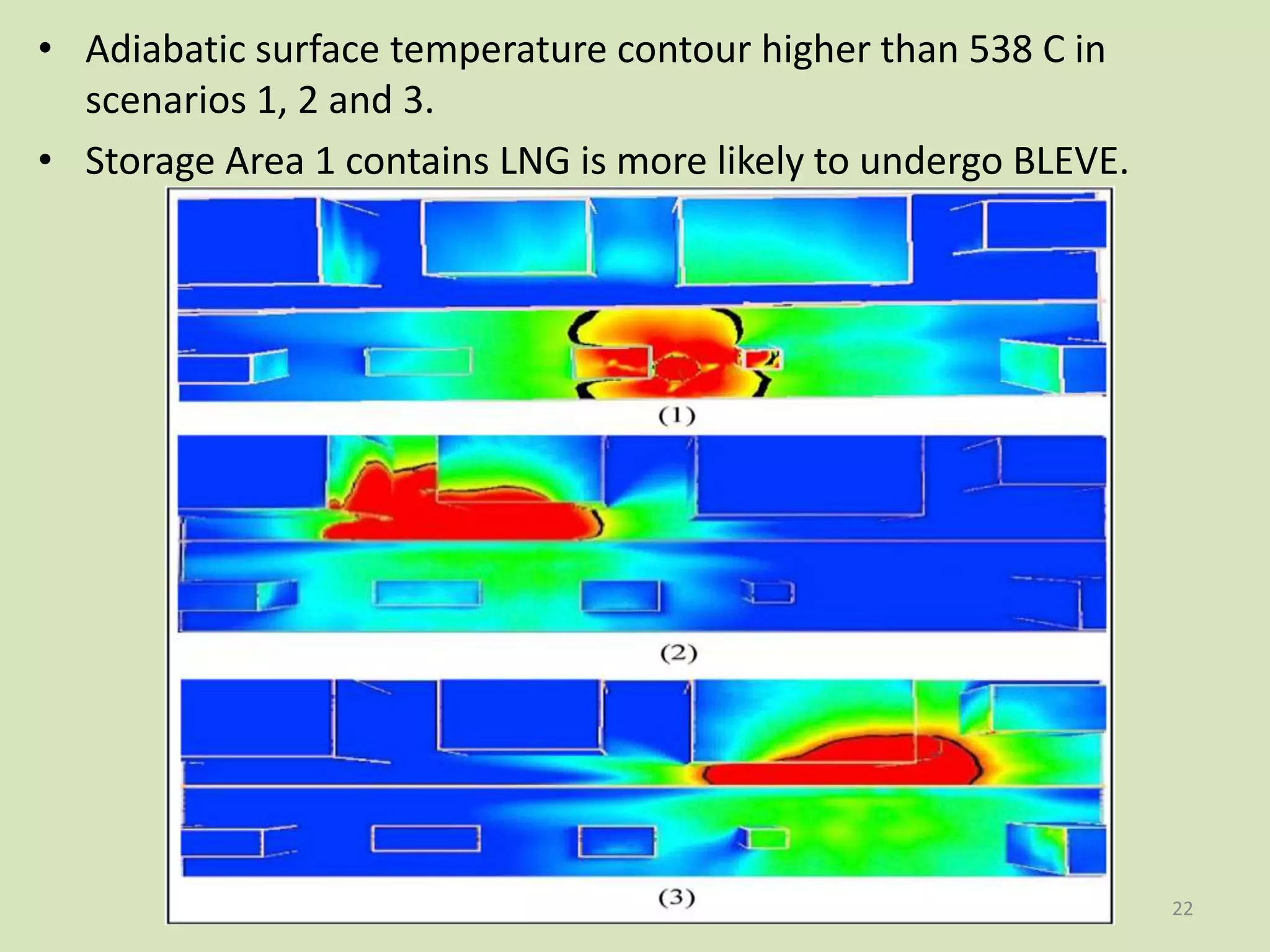

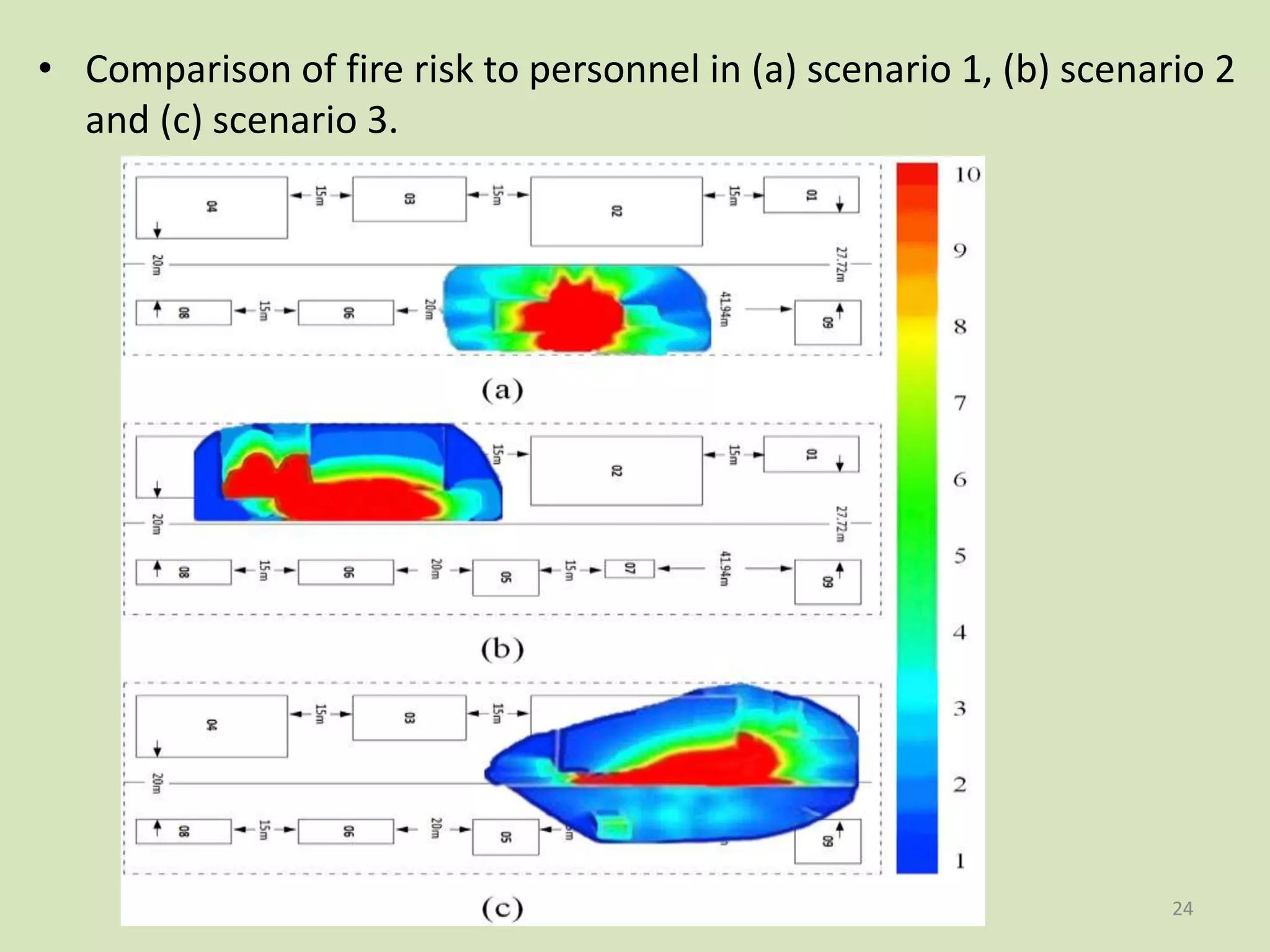

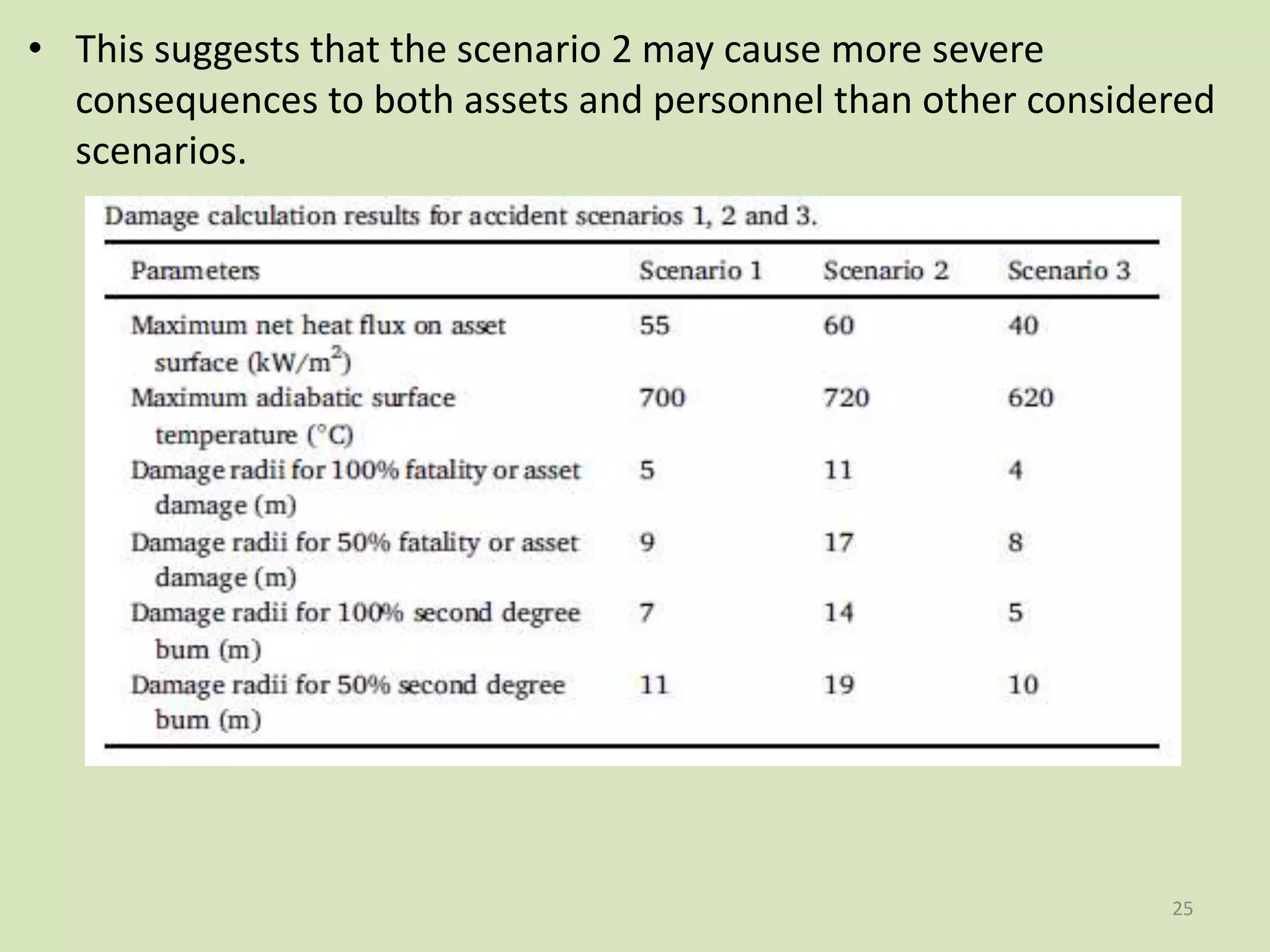

The document presents a methodology for assessing fire impact in floating liquefied natural gas (FLNG) processing facilities using computational fluid dynamics (CFD). It outlines nine steps to identify and analyze credible fire scenarios, assess their risks to personnel and assets, and establish safety measures to mitigate potential fire events. Key findings indicate that LNG spills and leaks pose significant risks, and the method provides valuable insights for enhancing fire safety design and systems.