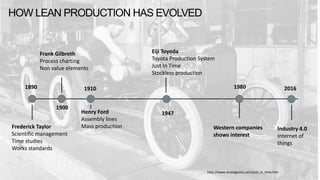

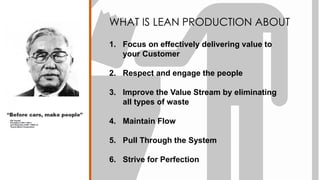

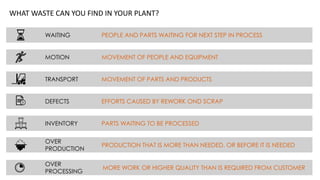

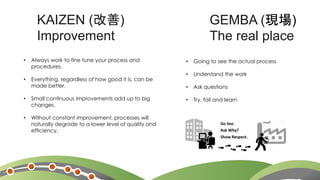

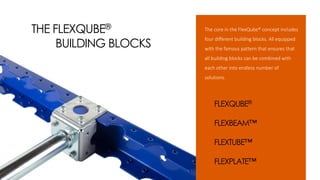

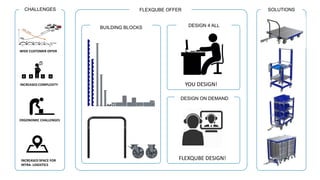

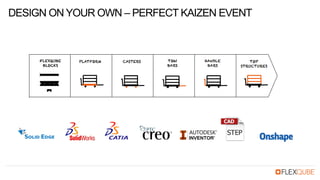

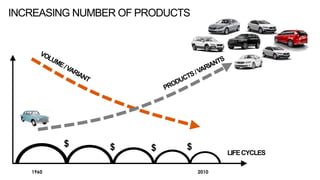

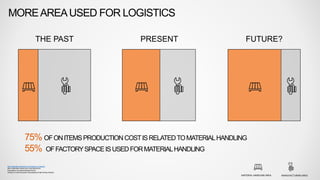

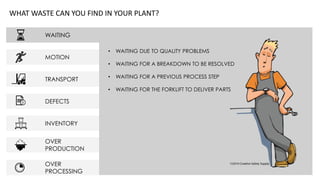

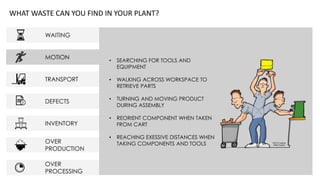

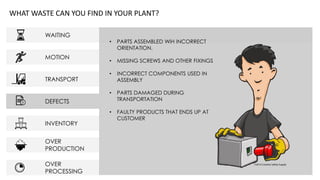

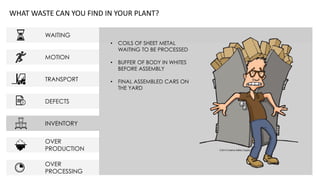

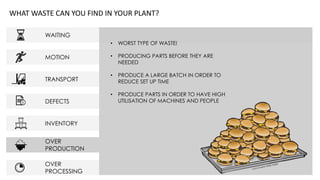

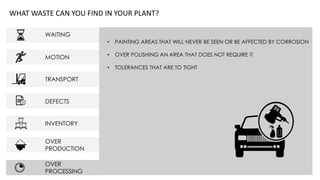

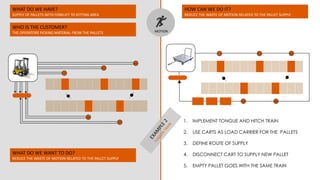

This document discusses the evolution and principles of lean production. It provides a brief history starting with Frederick Taylor's scientific management principles in the 1890s through Toyota's just-in-time production system developed in the 1940s-1980s. The core aspects of lean production are outlined as focusing on customer value, respecting people, eliminating waste, maintaining flow and pulling work through the system. Various types of waste are defined and the reader is asked to identify examples in their plant. Continuous improvement and going to see processes firsthand are emphasized. Potential applications of lean thinking to material handling and factory logistics are explored through examples.