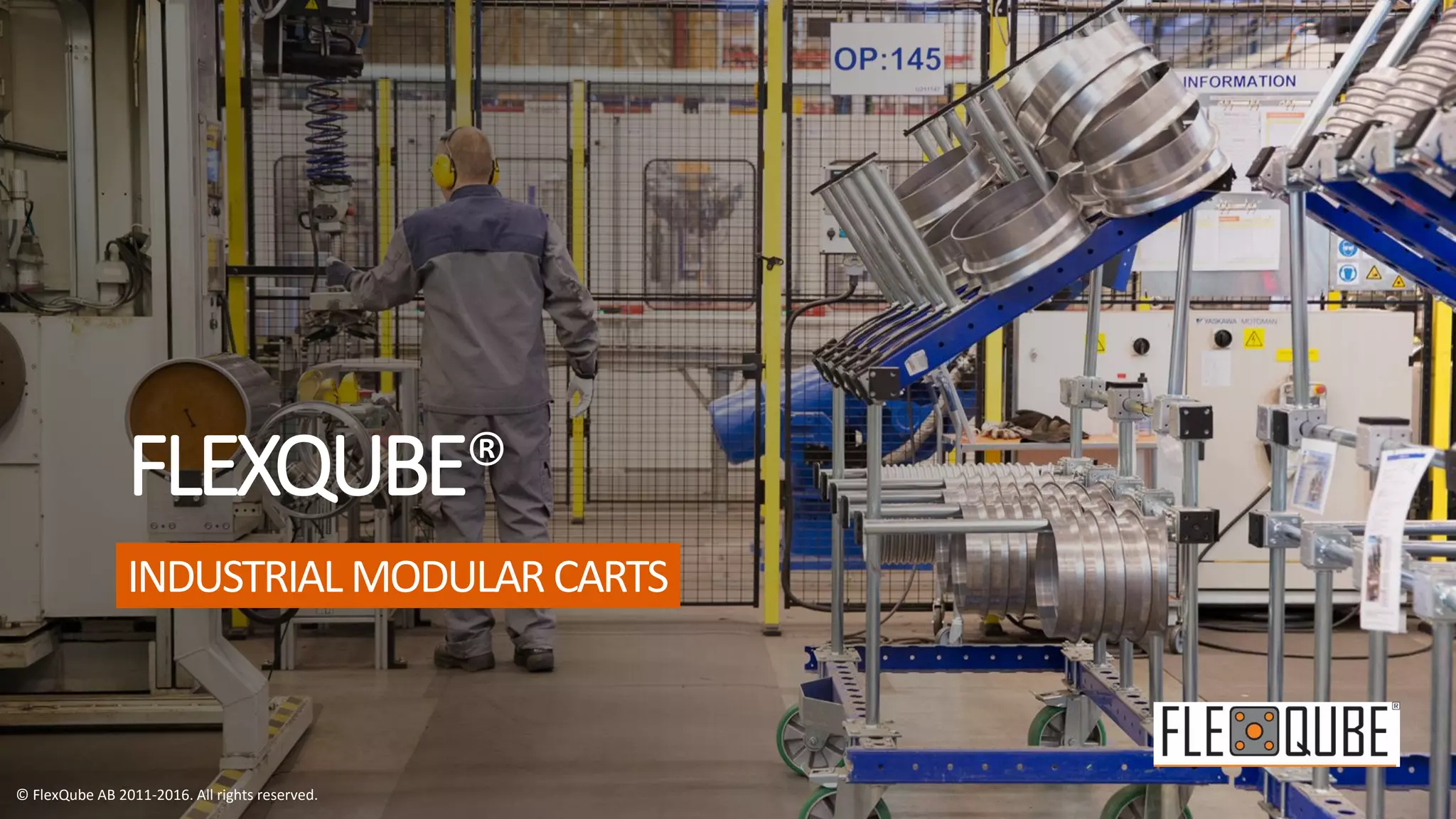

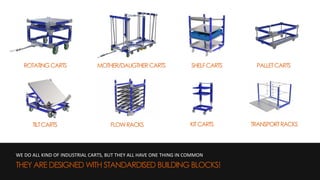

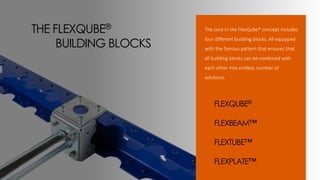

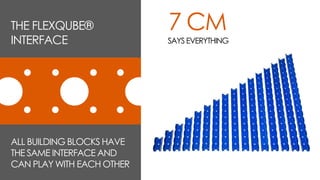

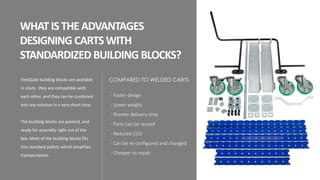

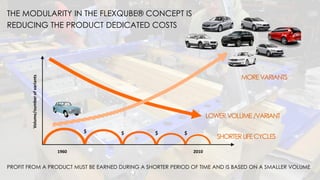

FlexQube designs industrial carts using standardized building blocks for enhanced modularity and compatibility, allowing for quick assembly and customization. Their approach reduces costs, improves reusability, and offers significant advantages over traditional welded carts in terms of weight, delivery time, and repairability. FlexQube also emphasizes safety and efficiency in material handling by promoting alternatives to forklifts, such as tugger trains.