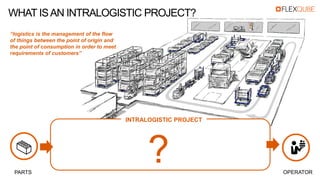

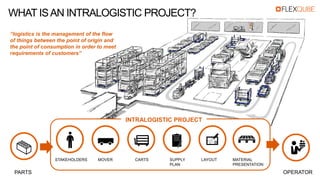

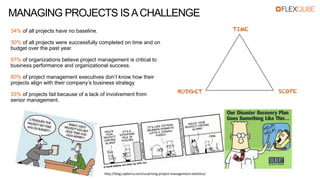

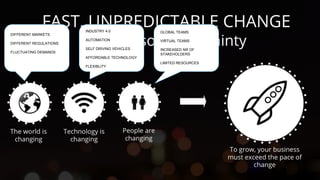

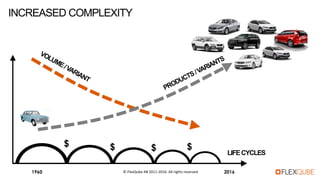

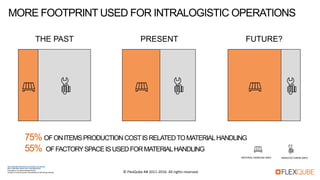

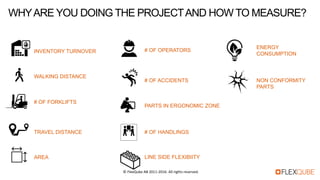

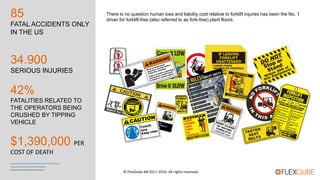

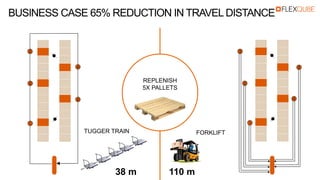

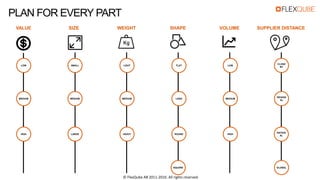

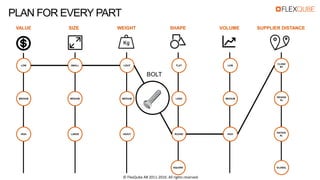

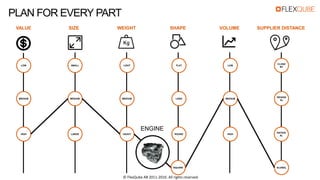

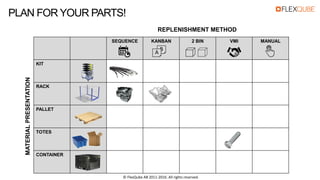

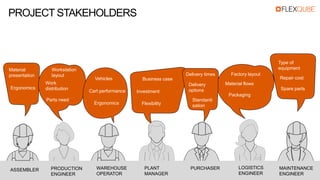

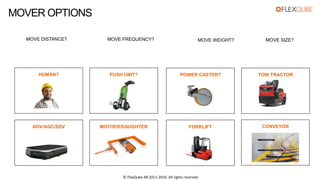

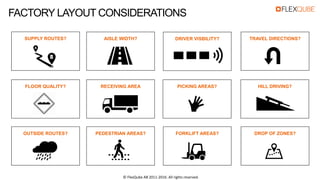

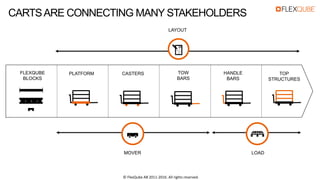

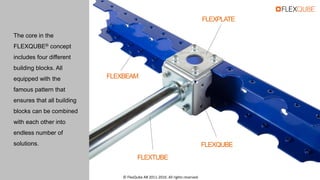

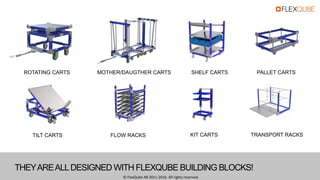

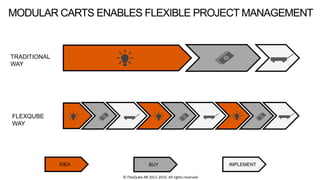

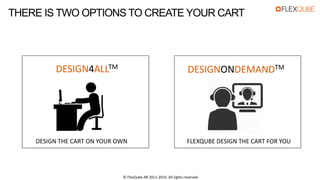

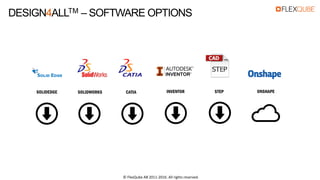

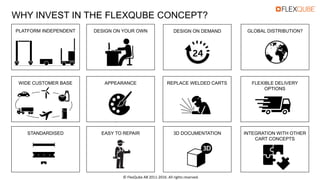

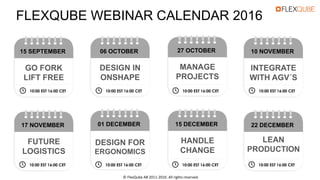

The document discusses managing intralogistic projects, emphasizing the importance of effective project management in logistics, which involves overseeing the flow of materials to meet customer demands. It highlights statistics on project outcomes, complexities, and safety concerns, particularly around forklift-related accidents, advocating for flexible, modular solutions through the FlexQube concept. Additionally, the document outlines design options and resources for creating customized material handling carts to enhance operational efficiency.