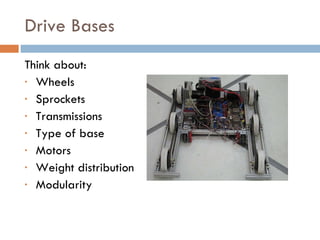

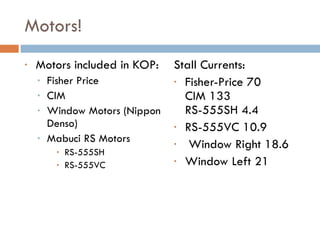

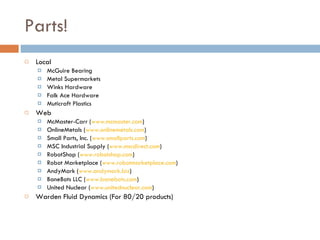

The document outlines the design process for robots in FIRST Robotics competitions. It discusses the importance of brainstorming with the whole team to generate ideas and categorize them. Computer-aided design is recommended, especially for set components, to demonstrate the robot's function. Key considerations for the design include weight distribution, goals of operation, simplicity, and types of motion. Components like drive bases, transmissions, framing options, and motors are discussed. Effective prototyping and sourcing parts from various suppliers is also covered.

![www.oregonfirst.com www.team1540.org [email_address]](https://image.slidesharecdn.com/firstfare2010-thedesignprocessandfirstrobotics-111016182038-phpapp02/85/First-fare-2010-the-design-process-and-first-robotics-22-320.jpg)