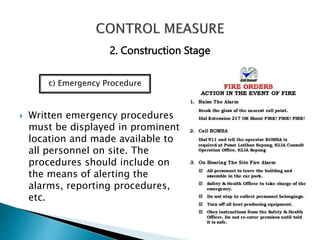

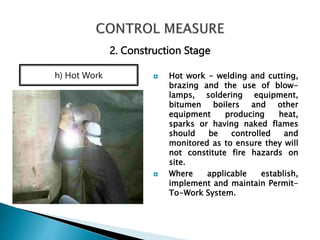

This document provides guidance on fire safety measures during construction stages. It outlines identifying fire hazards and statutory requirements. It recommends developing a fire safety plan with key roles and emergency procedures. It also gives guidelines on ensuring adequate extinguishers, securing hazardous materials, controlling hot work, safe electrical and mechanical equipment, and good housekeeping. The overall aim is preventing and controlling fire risks during construction through proper planning, coordination, and compliance with regulations.