Jimmy Chen presented on carbon management and enterprise resource planning (ERP). The presentation covered:

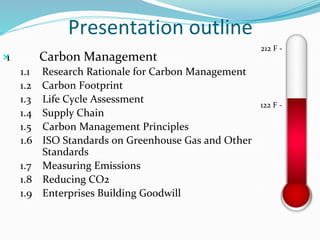

1. Carbon management principles including measuring carbon footprints through life cycle assessments, managing supply chain emissions, and standards like ISO.

2. How ERP systems can integrate carbon management by tracking emissions data and performing carbon calculations throughout the supply chain and business processes.

3. Open research issues like developing carbon management software that interfaces with existing ERP systems with minimal disruption and validating prototypes to evaluate feasibility.