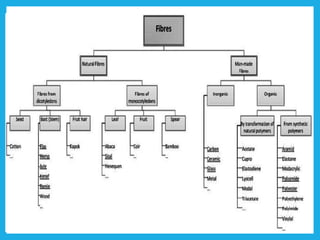

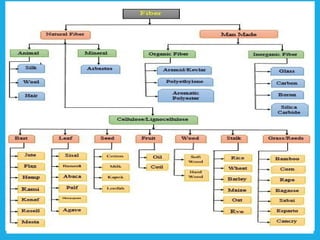

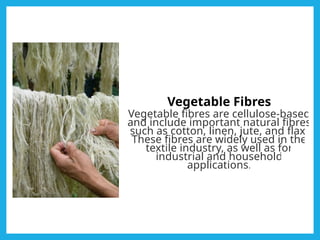

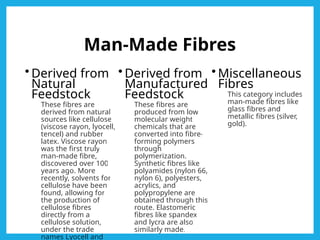

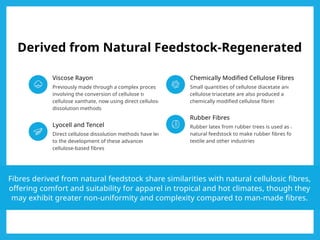

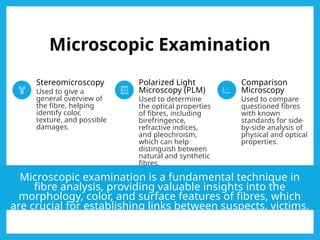

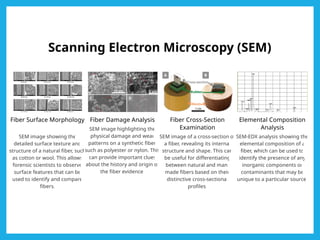

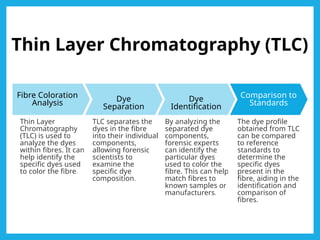

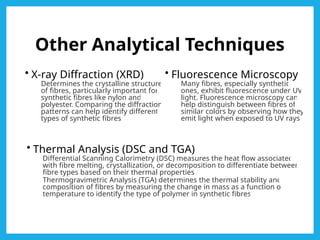

The document discusses the classification and examination of natural and man-made fibers, detailing their sources, properties, and production methods. It covers fiber types including vegetable, animal, and mineral fibers, as well as man-made options derived from both natural feedstock and manufactured feedstock. Furthermore, it outlines techniques for fiber analysis in forensic science, such as microscopic examination, spectroscopy, and thin-layer chromatography, emphasizing their importance in identifying and comparing fibers for investigative purposes.