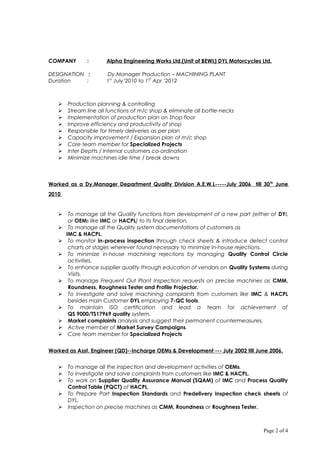

Adnan Nazim has over 20 years of experience in quality control and production management roles for various engineering companies. His experience includes managing quality functions, monitoring production processes, enhancing supplier quality, and investigating and resolving complaints. He holds a Bachelor's degree in Mechanical Engineering and has received professional training in CNC measurement and quality systems.