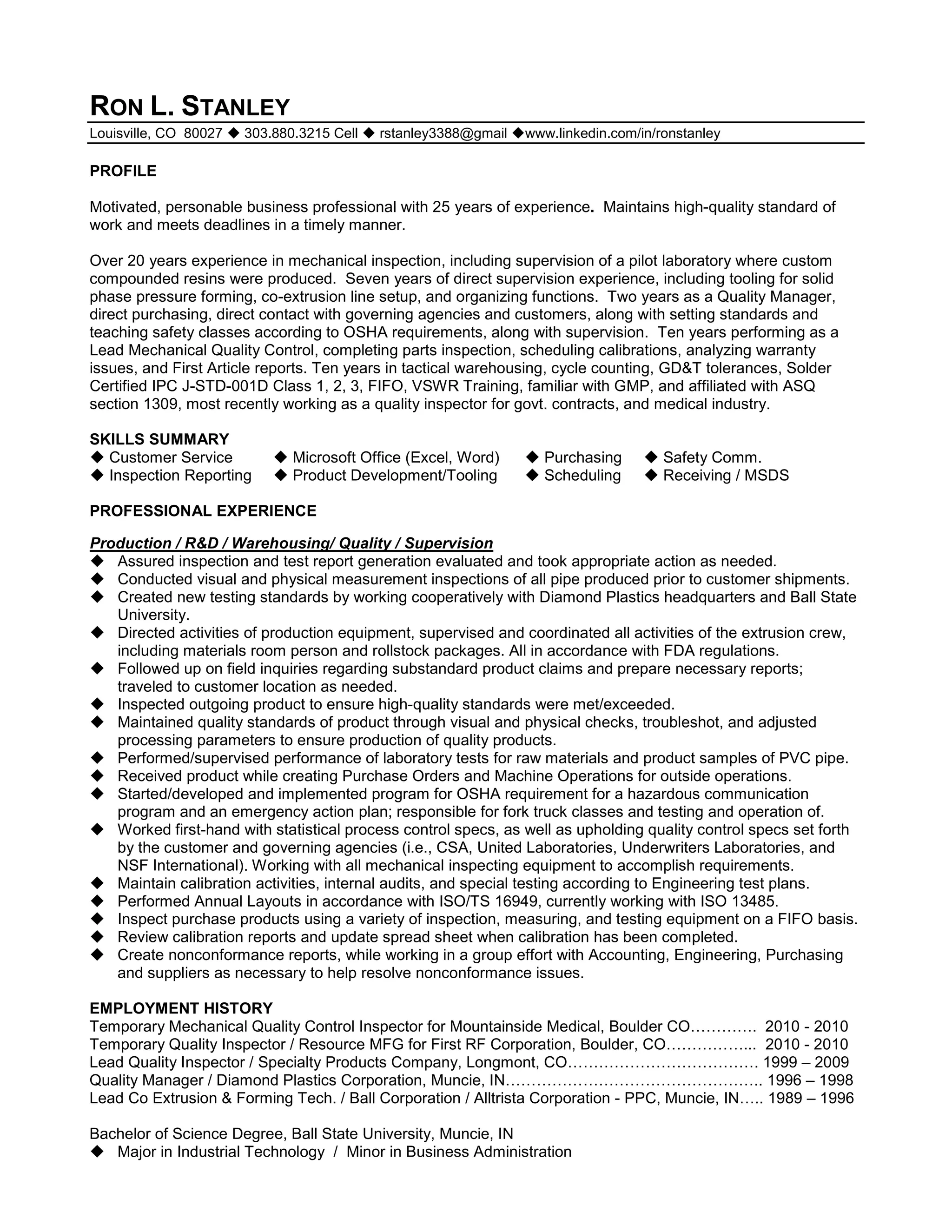

Ron Stanley is a quality control professional with over 25 years of experience in mechanical inspection, production, warehousing, and quality and supervision roles. He has extensive experience ensuring products meet high quality standards through inspection, testing, troubleshooting, and implementing quality control programs. Stanley also has management experience, including directly supervising production crews and serving as Quality Manager. He maintains various technical certifications and affiliations.