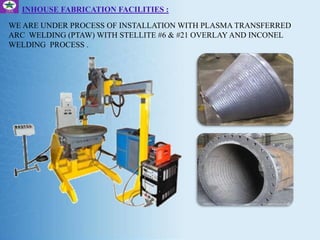

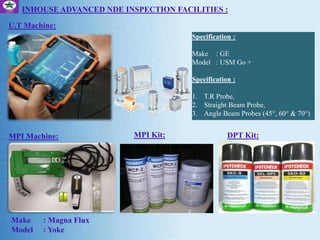

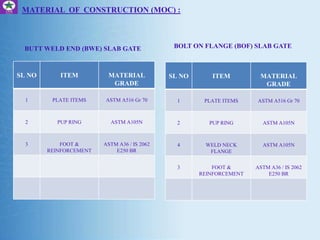

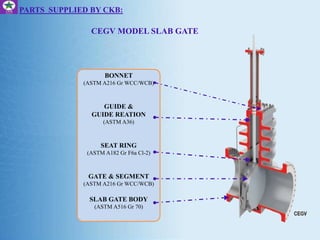

CKB Group specializes in heavy fabrication and CNC machining with advanced in-house facilities for inspection and NDE. The company is certified with ISO 9001, ISO 14001, and ISO 45001, and has received several awards for its contributions in the industry. Their product offerings include a range of valve designs and manufacturing processes, utilizing high-quality materials and modern technology.