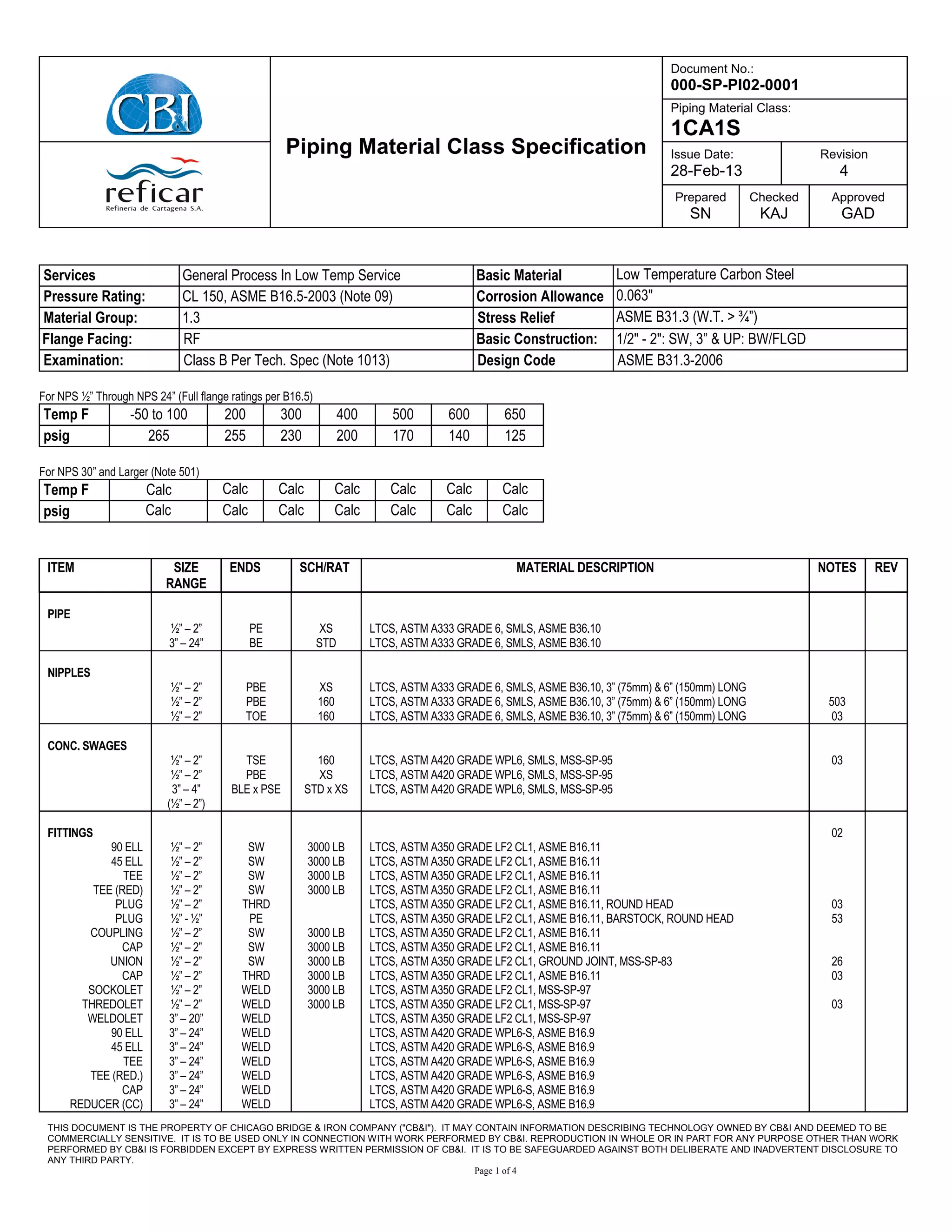

This document provides specifications for piping material class 1CA1S, including:

- Acceptable materials, sizes, standards, and manufacturers for pipe, fittings, valves, flanges and other components.

- Pressure and temperature ratings in various sizes from -50 to 650 degrees F and 125 to 265 psig.

- Notes on exceptions and limitations for certain components.

- A branch connection chart showing acceptable fittings for connecting pipes of different sizes.