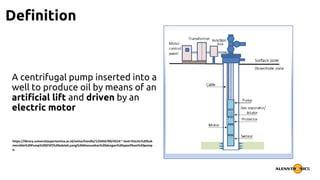

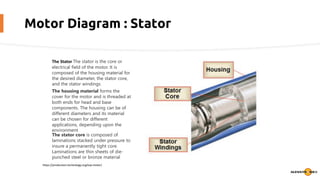

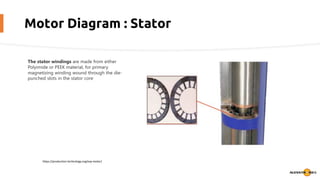

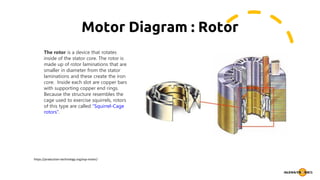

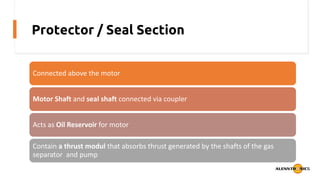

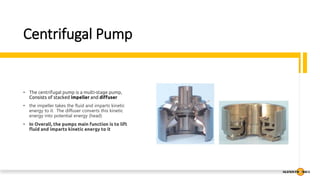

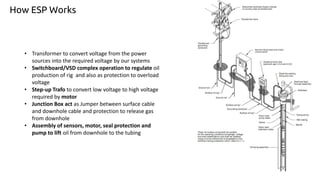

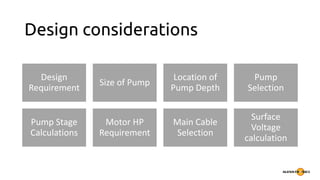

ESP is an electric submersible pump inserted into oil wells to produce oil using artificial lift driven by an electric motor. ESPs are important for regulating oil and gas production and are a low maintenance and cost effective artificial lift method. The main ESP components are the motor, seal section, intake, power cable, and centrifugal pump. ESPs work by using a motor to drive a centrifugal pump via a shaft, lifting fluid up the well. Design considerations for ESPs include pump size and depth, motor HP requirement, and cable selection. ESPs are used widely in oil and gas production as well as other industries. Their advantages include a wide range of applications and capacities, ability to handle deep wells, and being anti-