This technical presentation provides an overview of float cum boost battery chargers used for standby applications. It discusses:

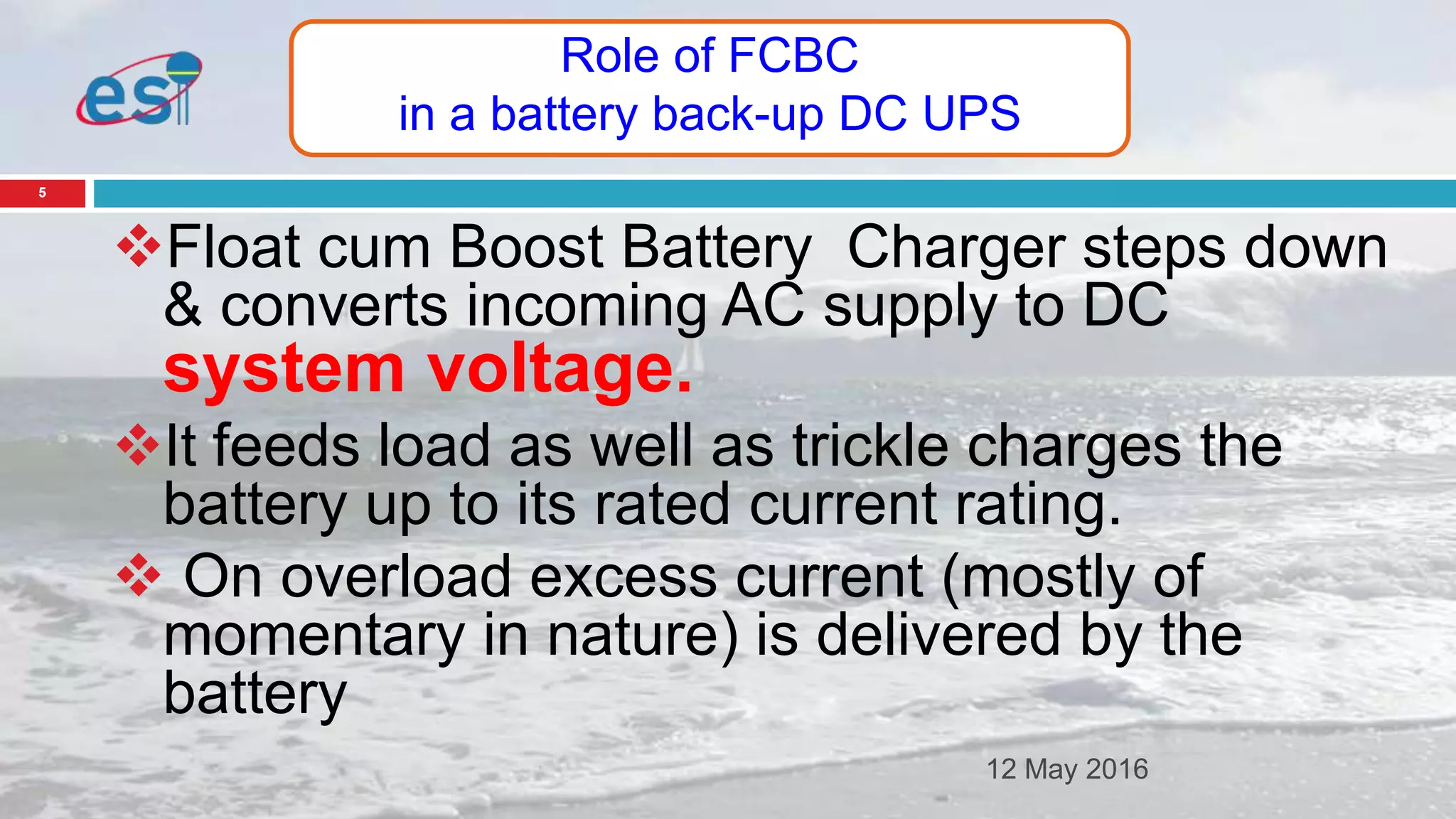

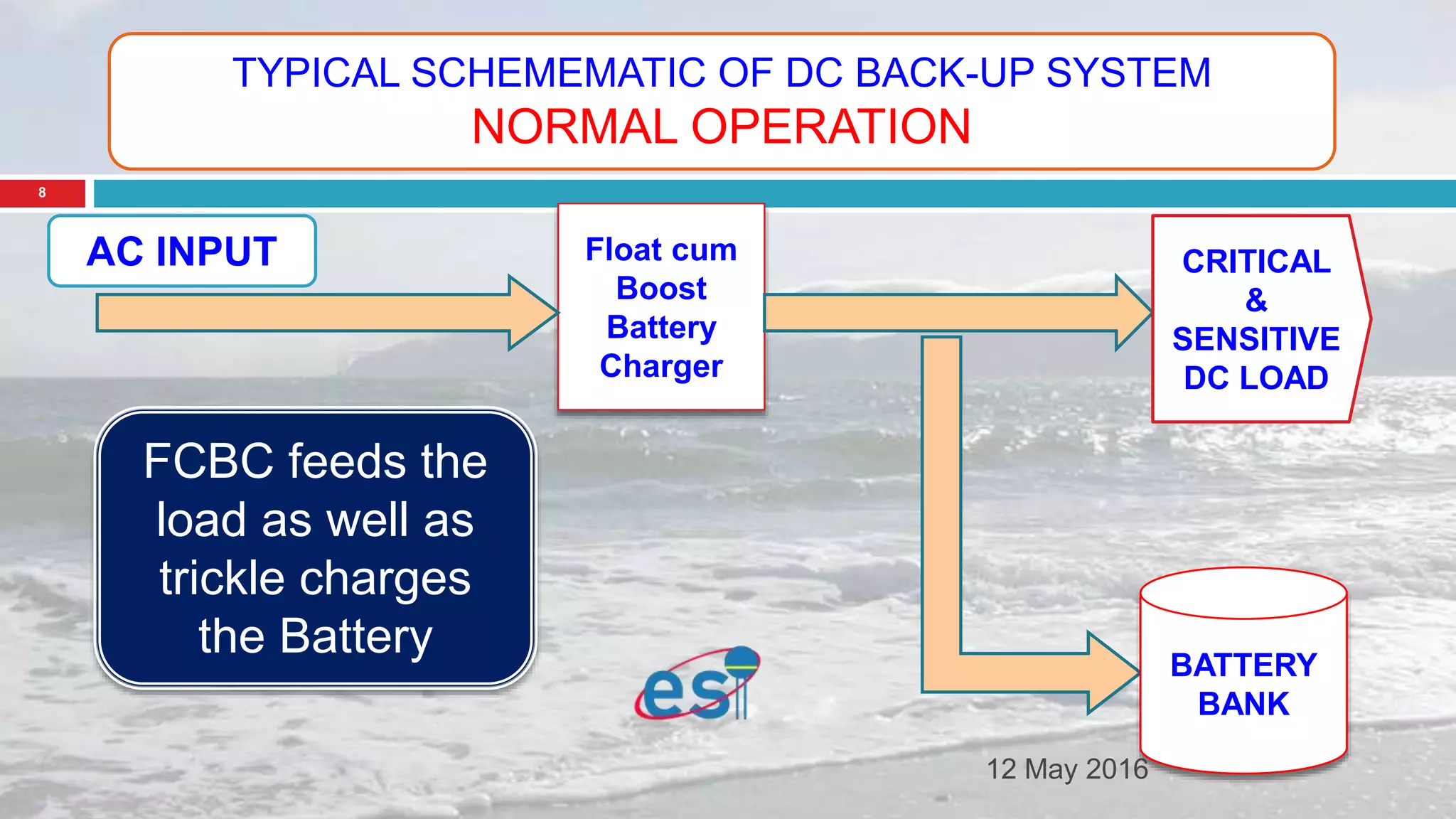

1) What a float cum boost battery charger is and its role in an uninterruptible DC power supply system.

2) The topologies of float cum boost battery chargers, including single and dual rectifier designs.

3) The technical specifications of thyristor-controlled float chargers, including input/output voltages, regulation, protections, and construction.

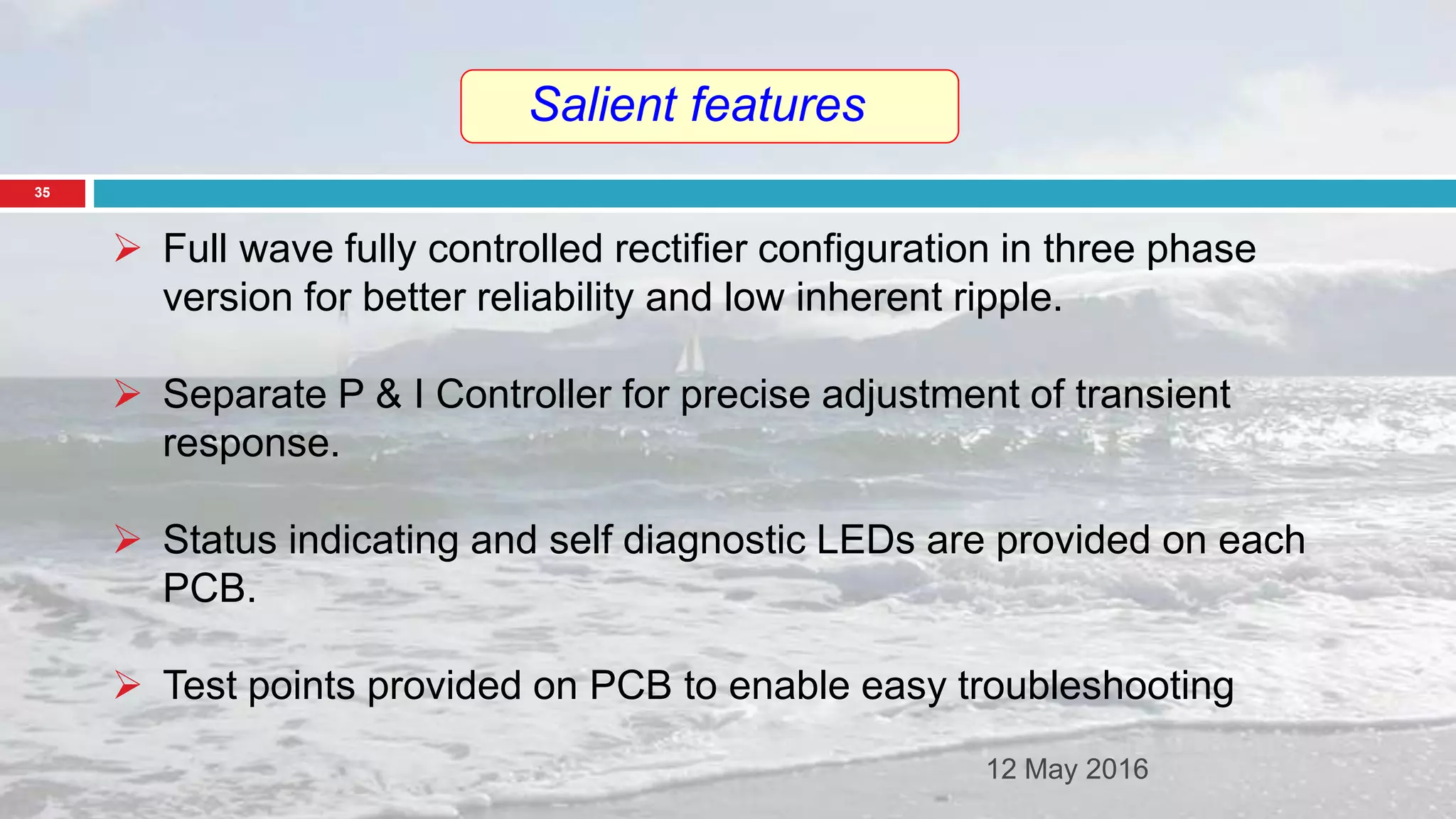

4) Salient features of thyristor-controlled float chargers like precise control, temperature compensation, automatic charging profiles, and modular design.

5) Present trends in converter technology moving from thyristor

![K1, DC1 -

CLOSED

K2-OPEN

FLOAT

RECTIFIER

[ON]

AC INPUT

BOOST

CHARGER

[OFF]

DC DISTRI-

-BUTION

BOARD

BATTERY

BANK

DC1

K1

K2

STAGE-1 :

NORMAL

OPERATION

Float rectifier feeds the load and trickle charges the Battery.

Boost charger remains in stand by OFF position

12 May 2016

16](https://image.slidesharecdn.com/fcbcpptver1-160512071353/75/ESI-Electro-Service-India-Float-Cum-Battery-Charger-16-2048.jpg)

![DC1 -CLOSED

K1, K2-OPEN

FLOAT

RECTIFIER

[NO SUPPLY]

AC INPUT

BOOST

CHARGER

[NO SUPPLY]

DC DISTRI-

-BUTION

BOARD

BATTERY

BANK

DC1

K1

K2

STAGE-2 :

POWER

OUTAGE

BATTERY BACK UP PERIOD

Battery feeds the Load

12 May 2016

17](https://image.slidesharecdn.com/fcbcpptver1-160512071353/75/ESI-Electro-Service-India-Float-Cum-Battery-Charger-17-2048.jpg)

![K1, K2 -

CLOSED

DC1-OPEN

FLOAT

RECTIFIER

[ON]

AC INPUT

BOOST

CHARGER

[ON]

DC DISTRI-

-BUTION

BOARD

BATTERY

BANK

DC1

K1

K2

STAGE-3

POWER

RESTORATION

BOOST CHARGING OF BATTERY AFTER DEEP DISCHARGE

Boost charger charges Battery when Float rectifier feeds load

12 May 2016

18](https://image.slidesharecdn.com/fcbcpptver1-160512071353/75/ESI-Electro-Service-India-Float-Cum-Battery-Charger-18-2048.jpg)

![K1, DC1 -

CLOSED

K2-OPEN

FLOAT

RECTIFIER

[ON]

AC INPUT

BOOST

CHARGER

[OFF]

DC DISTRI-

-BUTION

BOARD

BATTERY

BANK

DC1

K1

K2

STAGE-4:

BATTERY

CHARGED

Back to NORMAL operation.

Float rectifier feeding the load and trickle charging the Battery.

Boost charger remains in stand by OFF position

12 May 2016

19](https://image.slidesharecdn.com/fcbcpptver1-160512071353/75/ESI-Electro-Service-India-Float-Cum-Battery-Charger-19-2048.jpg)

![K1, K2 -

CLOSED

DC1-OPEN

AC INPUT

BOOST

CHARGER

[ON IN

FLOAT

MODE]

DC DISTRI--

BUTION

BOARD

BATTERY

BANK

DC1

K1

K2

STAGE-5

FLOAT RECT.

FAILED

EMERGENCY FLOAT MODE

Boost charger acts as Float rectifier feeding the load and

charging the Battery

12 May 2016

20](https://image.slidesharecdn.com/fcbcpptver1-160512071353/75/ESI-Electro-Service-India-Float-Cum-Battery-Charger-20-2048.jpg)

![SIX

PULSE

TRIGGER

CUM

CONTRO

L

PCB

[MOTHER

BOARD]

OUTPUT TO

6-PULSE

TRAFO

USER CONTROL POTS

12 May 2016

26](https://image.slidesharecdn.com/fcbcpptver1-160512071353/75/ESI-Electro-Service-India-Float-Cum-Battery-Charger-26-2048.jpg)