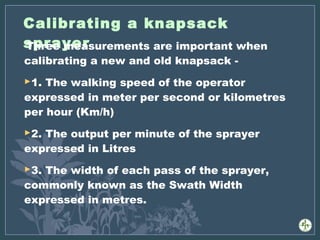

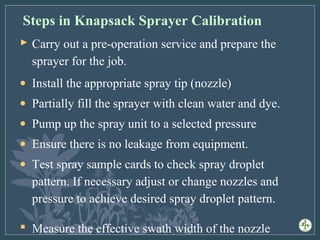

This document discusses calibrating a knapsack sprayer for effective and safe herbicide use. Calibration ensures the correct herbicide rate is applied to avoid crop damage, pollution, and waste. It should be done when starting with a new sprayer, at the start of each season, after nozzle or pressure changes, or after 100 hectares of spraying. Key factors that affect calibration include canopy density, nozzle type and pressure, and ground conditions. The calibration process involves measuring the operator's walking speed, sprayer output, and swath width to determine the spray volume applied per hectare.