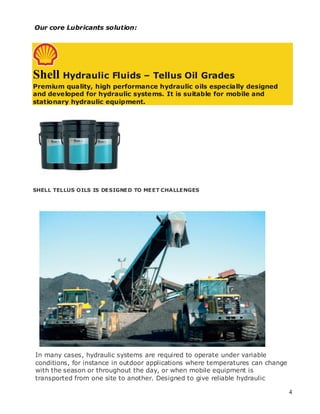

Epoxy Oilserv Nigeria Limited is an authorized distributor of Shell lubricants in Nigeria. They provide a full range of automotive and industrial lubricants including Shell's line of hydraulic fluids, gear oils, greases, and other products. Their management team has extensive experience and they have offices in Port Harcourt and Lagos to serve customers across Nigeria.