The document provides an overview of heating, ventilation, and air conditioning (HVAC) systems. It defines HVAC as controlling temperature, humidity, and air quality inside buildings. It describes the basic components and functions of heating, cooling, ventilation, and air conditioning systems. It also explains refrigeration cycles and common refrigerants used in HVAC systems. The document is classroom notes that cover HVAC topics like components, functions, types of heating/cooling systems, and refrigeration principles.

![MOHAMMED ABDUL RAZZAK HVAC CLASS NOTES

P a g e 2 | 74

Supply air used for ventilation is filtered and cooled and/or heated inside Air Handling

Units.

This system is further classified into 2 sub-systems:

1. Fresh Air System: In Fresh Air System, fresh ambient air is been supplied from outdoor

environment to the indoor space to maintain oxygen requirement in the room. This air

can be partially or completely treated before been supplied to the room space.

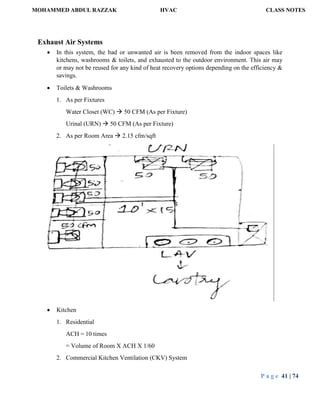

2. Exhaust Air System: In this system, the bad or unwanted air is removed from the indoor

space to the outdoor environment.

Air-conditioning: It is defined as the process of conditioning or modification of air as per the

indoor conditions like temperature, moisture levels (humidity), dust levels, noise levels and

smell/odor.

It refers to the cooling and dehumidification of indoor air for thermal comfort.

Air conditioning systems are designed to stabilize the air temperature and humidity

within an area.

Excess heat from the circulating air is usually removed by a cooling coil that is supplied

with cold water / refrigerant.

To decrease relative humidity the circulating air needs to be cooled to a temperature

below the dew point and then heated back to meet the requirement.

HVAC systems control the temperature, humidity, and quality of air in buildings to a set

of chosen conditions.

The term ‘Refrigeration’ may be defined as the process of removing heat from a

substance under controlled conditions. It also includes the process of reducing and

maintaining the temperature of a body below the general temperature of its surroundings.

In other words, the refrigeration means a continued extraction of heat from a body whose

temperature is already below the temperature of its surroundings.

The basic motive of designing an HVAC system for the building industry is to maintain the

human comfort conditions inside the building space.

Human Comfort Condition:

- Temperature: 24.4o

C / 76o

F

- Relative Humidity: 50 %

- Air Quality: Fresh Air for Oxygen, Dust Filtration, Noise Criteria (NC) [25 – 50], Smell /

Odor](https://image.slidesharecdn.com/entrylevelhvac-221031083613-17d05f8b/85/ENTRY-LEVEL-HVAC-pdf-2-320.jpg)

![MOHAMMED ABDUL RAZZAK HVAC CLASS NOTES

P a g e 21 | 74

2. Building Requirement

a. Window A/C (1 – 2 TR)

- Technically not feasible

- No. of Machines are more / cost is also more

- Maintenance is more

- No fresh air option

- Building look is spoiled

b. Split A/C (1 – 3 TR)

c. Cassette A/C (1.5 – 4 TR)

d. Verticool A/C (2.5 – 4.5 TR)

- Technically feasible

- No. of machines are more

- Maintenance is more

- No fresh air

- Building look is spoiled

e. Package A/C (Roof Top Units – RTUs) [5 – 25 TR]

- Technically feasible

- No. of machines are less

- Maintenance is less

- Fresh air is available

- Ducting is required

f. VRF/VRV A/C (5 – 150 TR) [R-410 is used]

- Technically feasible

- No. of machines can be less

- Initial cost is less

- Maintenance cost is more

- Fresh air is possible

- Ducting is optional](https://image.slidesharecdn.com/entrylevelhvac-221031083613-17d05f8b/85/ENTRY-LEVEL-HVAC-pdf-21-320.jpg)

![MOHAMMED ABDUL RAZZAK HVAC CLASS NOTES

P a g e 22 | 74

- Piping length: Lmax = 150 m

g. Centralized Chilled Water System (Chiller, FCU/AHU, Pump) [100 – 300 TR &

Above]

- Technically feasible

- No. of machines are less

- Maintenance is less

- Initial cost is very high

- Fresh air is possible

- Ducting / Piping are required

i) FCU Selection: Fan Coil Unit (1 – 5 TR) depends on Brand

ii) AHU Selection: Air Handling Unit (5 – 100 TR & Above) depends on Brand

iii) Chiller Selection: Depends on Brand

iv) Pump Selection: It can be done only after having the final piping shop drawing.

(Later in the Project).

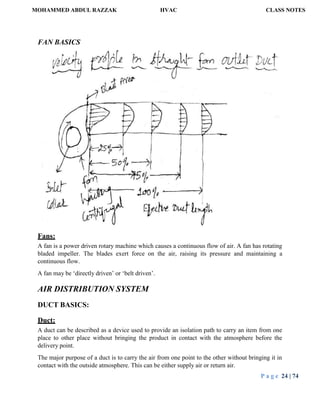

HVAC System Components:

The basic components in a common central HVAC system are:

1. Fan(s) to circulate the supply air (SA) and return air (RA).

2. Supply air ductwork in which the air flows from the supply fan to the conditioned space.

3. Air devices such as supply air outlets and return air inlets.

4. Return air path or ductwork in which the air flows back from the conditioned space to the

mixed air chamber (Plenum).

5. Outside air (OA) device such as an opening, louver or duct to allow for the entrance of

outside air into the mixed air chamber.

6. Mixed air chamber to receive the return air and mix it with outside air.

7. Filter section(s) to remove dirt and dust particles from the mixed air.

8. Heat exchanger(s) such as hot water coil(s), steam coil(s), refrigerant evaporator(s), or

chilled water coil(s) to add heat to or remove heat from the circulated air.

9. Auxiliary heating devices such as natural gas furnace(s) or electric heating element(s).](https://image.slidesharecdn.com/entrylevelhvac-221031083613-17d05f8b/85/ENTRY-LEVEL-HVAC-pdf-22-320.jpg)

![MOHAMMED ABDUL RAZZAK HVAC CLASS NOTES

P a g e 28 | 74

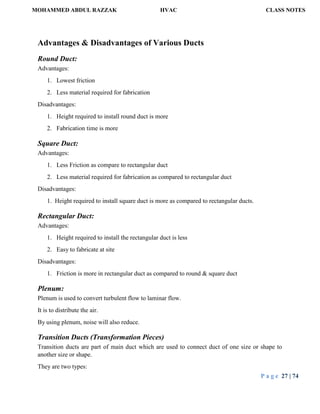

a. Reducer – Concentric, Eccentric (Flat on Bottom & Flat on Top)

b. Enlarger

Recommended GI Sheet Metal Gauge

Rectangular Duct

Size (mm)

Gauge Sheet

Thickness

(mm)

Up to 750 24 0.63

750 to 1500 22 0.80

1500 to 2250 20 1.00

More than 2250 18 1.25

For Plenum 18 1.25

Designing of Ducting System

Points to be considered while designing a ducting system:

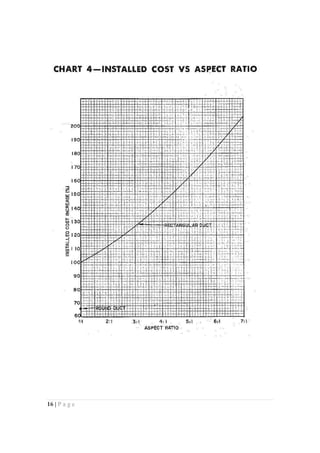

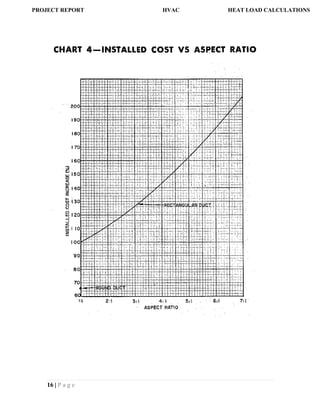

1. Aspect Ratio = Long Side of Duct / Short Side of Duct [W/H or H/W]

Best Aspect Ratio = 1:1 (450 x 450)

Maximum permissible Aspect Ratio = 4:1 (800 x 200)

2. False Ceiling Height](https://image.slidesharecdn.com/entrylevelhvac-221031083613-17d05f8b/85/ENTRY-LEVEL-HVAC-pdf-28-320.jpg)

![MOHAMMED ABDUL RAZZAK HVAC CLASS NOTES

P a g e 30 | 74

4. Co-ordination with other services

[ISD – Individual Service Drawing & CSD – Combined Service Drawing]

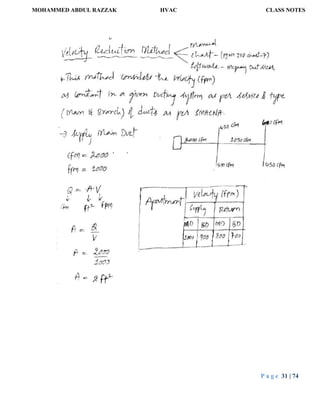

Duct Designing Methods

1. Velocity Reduction Method – This method considers the velocity (fpm) as constant in a

given ducting system as per service & type (Main Vs Branch) of ducts as per SMACNA.](https://image.slidesharecdn.com/entrylevelhvac-221031083613-17d05f8b/85/ENTRY-LEVEL-HVAC-pdf-30-320.jpg)

![MOHAMMED ABDUL RAZZAK HVAC CLASS NOTES

P a g e 48 | 74

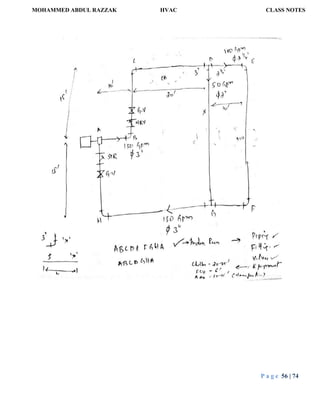

2. Chillers

3. FCU / AHU

4. Diffusers

Transport Systems:

1. Piping

2. Ducting

Refrigeration:

1. Vapor Absorption System

2. Vapor Compression System

It is further classified as

a. DX Systems [Refrigerant Air (Single Stage)]

b. Chilled Water Systems [Refrigerant CHW/Brine Air (Double Stage)]

Central Hydronic Air Conditioning System:

What should be chilled water of refrigerant temperature?

Classification as per ASHRAE](https://image.slidesharecdn.com/entrylevelhvac-221031083613-17d05f8b/85/ENTRY-LEVEL-HVAC-pdf-48-320.jpg)

![MOHAMMED ABDUL RAZZAK HVAC CLASS NOTES

P a g e 50 | 74

COOLING TOWERS:

Similar concept as evaporative condensers

Condenser water ‘’Open’’ in the tower

Some water evaporates, requiring make-up water

Some systems eliminate the fan requirement

PIPING SYSTEM:

A pipe is a cylindrical conduit used for the transportation of fluids and solids from one

place to another under pressure.

Fluids: Liquids (Ex: Water) & Gas (Ex: Steam)

Solids: Ex. Powder & Pellets

Semi-solids: Ex. Slurry

- The piping system in centralized HVAC system is a closed type. The closed systems are

made up of two components:

a. A supply system that ends at a terminal air conditioning equipment unit.

b. A return system that starts at the terminal equipment

Designation of Pipe Size: Nominal Pipe Size (NPS)

[ND of pipe in inches – provides OD as per standard]

Designation of Pipe Thickness: Schedule Number (Wall thickness of pipe in inches)

Pipe length are commercially provided in as,

1. Single Random Length = 20 ft. or 6 m

2. Double Random Length = 40 ft. or 12 m

3. Customized Length = As per Customer Requirement

During the procurement of piping system, we have consider these three facts of pipe:

1. Designation of pipe size

2. Designation of pipe thickness

3. Pipe length

Pipe Manufacturing Methods:

1. Seamless (Not Welded)](https://image.slidesharecdn.com/entrylevelhvac-221031083613-17d05f8b/85/ENTRY-LEVEL-HVAC-pdf-50-320.jpg)

![MOHAMMED ABDUL RAZZAK HVAC CLASS NOTES

P a g e 72 | 74

Manometer are simple and accurate pressure measuring instrument which utilize the pressure

that will lift a column of liquid. Water or mercury are the two common liquid used. The U-Tube

Manometer is the simplest arrangement. One end of the manometer is connected to the location

where pressure is to be measured, and other is usually open to the atmosphere. The reading on

the manometer is therefore gauge pressure.

Bourdon Pressure Gauge: It is a most commonly used type for installation in pipeline & in

vessels. This type of gauge is rugged & reliable and relatively in-expensive. It is not suitable for

reading very small pressure differences.

Measurement of Velocity:

For very approximate air velocity steady smoke can be use. The smoke generated by a

mechanical device or candles (smoke emitters) is injected in the air stream and absorb more

practical use of smoke is to examine the air distribution pattern in a room & to find air leakages

in ducts.

Silicon sealant is used to close the duct leakage.

Anemometer & Pilot Tube are most frequently used for measuring air velocities.

Client Handover:

Project handover to client after commissioning of the project, as per project specifications.

- As Built Drawings

- Inspection Request (IR) close out

- Site Instructions (SI) close out

- Engineer’s Instructions (EI) close out

- Operation & Maintenance ( O & M) manuals

International HVAC Standards

SMACNA – Sheet Metal Air Conditioning Contractor’s National Association [HVAC

Duct construction standard, Metal & Flexible, second edition – 1995]

NFPA – National Fire Protection Association [Standard for the installation of Air

Conditioning and Ventilating Systems]

UL – Underwriters Laboratories, Inc. [UL-555 Fire Dampers & Ceiling Dampers]

ARI – Air Conditioning and Refrigeration Institute [ARI 650 – Standard for Air Outlets

& Inlets]

ASHRAE – American Society of Heating Refrigeration & Air Conditioning Engineers

[Handbook, Systems and Equipment Volume]](https://image.slidesharecdn.com/entrylevelhvac-221031083613-17d05f8b/85/ENTRY-LEVEL-HVAC-pdf-72-320.jpg)

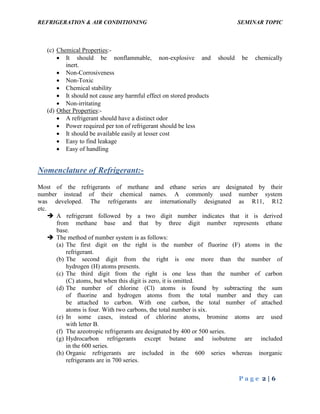

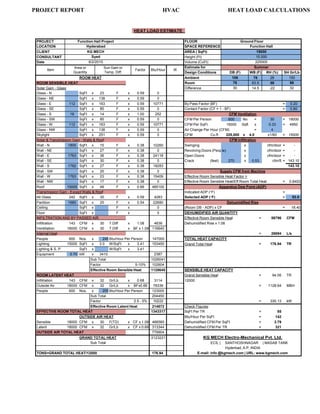

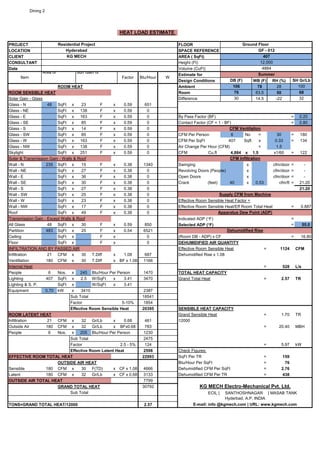

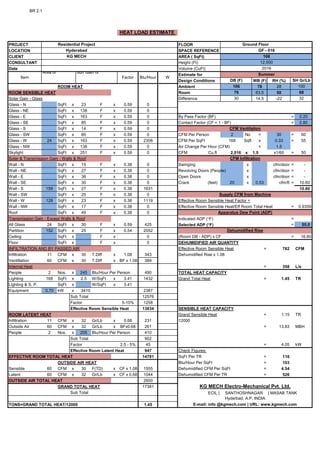

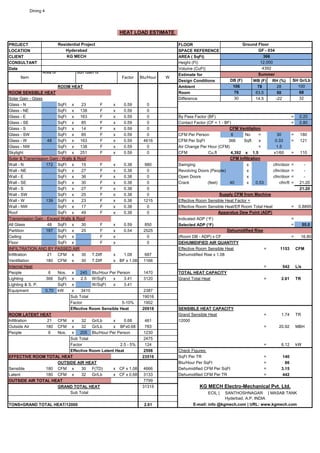

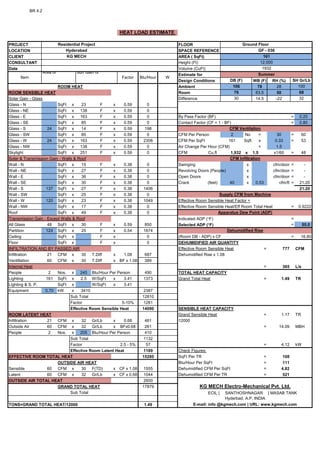

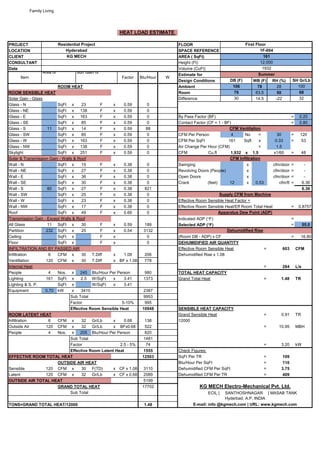

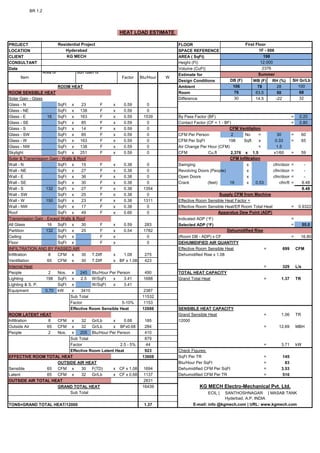

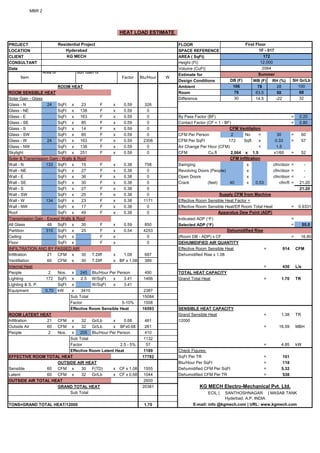

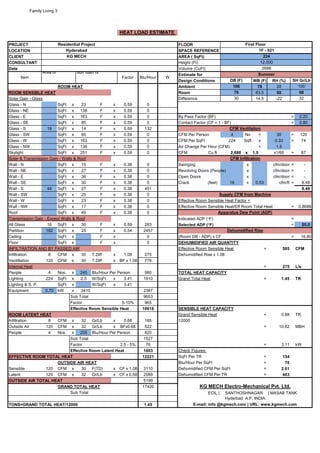

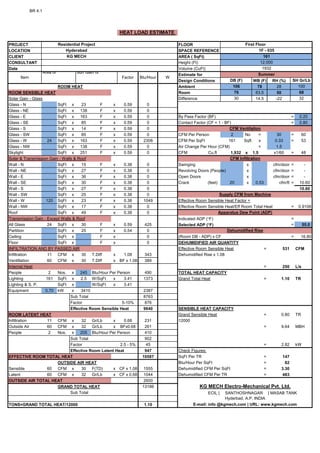

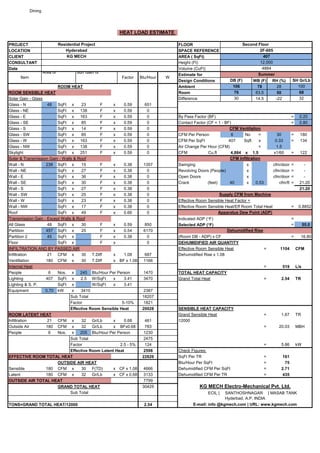

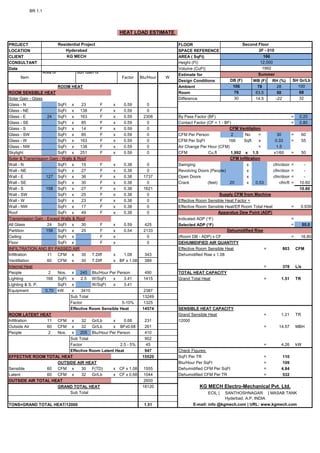

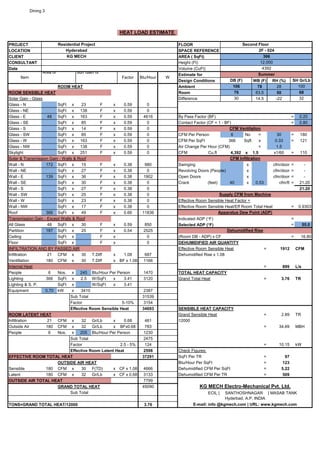

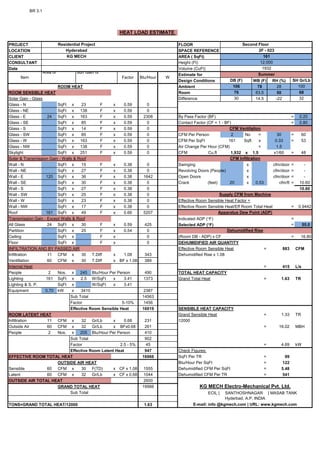

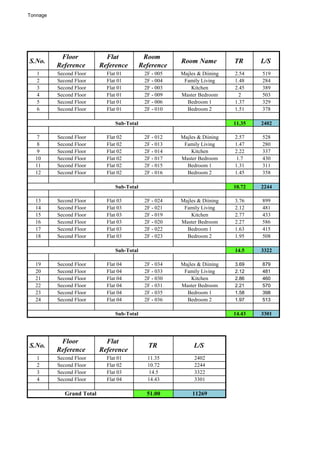

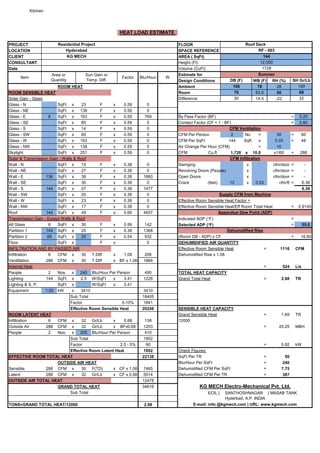

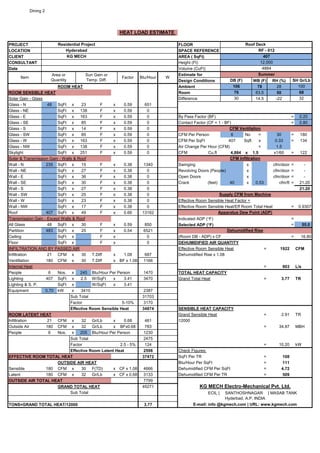

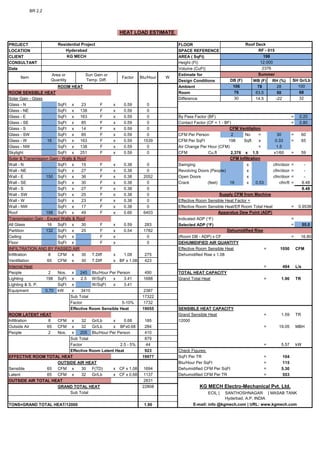

![PROJECT REPORT HVAC HEAT LOAD CALCULATIONS

P a g e 2 | 49

Square = S x S

Rectangle = L x B

Triangle = ½ bh

Temperature Difference: Refer Table – 15 for Solar Heat Gain through Glasses

S.No. Direction Temperature

Difference

1 North 23

2 Northeast 138

3 East 163

4 Southeast 85

5 South 14

6 Southwest 85

7 West 163

8 Northwest 138

9 Horizontal 251

Temperature Difference for Glass depends on

i. Orientation of Building

ii. Latitude of the Project

iii. Peak Timing (Month of Year/Time of Day)

Temperature Difference for Walls & Roofs is given by a formula:

TD for Walls & Roofs = Equivalent Temperature + Correction Factor

(Equivalent Temp. for Walls, Refer Table – 19)

(Equivalent Temp. for Roofs, Refer Table – 20)

(Correction Factor for Walls & Roofs, Refer Table – 20a)

Equivalent Temperature for Walls & Roofs depends on

i. Orientation of the Building

ii. Weight Density of Walls & Roofs (lb/sqft) [Refer – Table 21]](https://image.slidesharecdn.com/entrylevelhvac-221031083613-17d05f8b/85/ENTRY-LEVEL-HVAC-pdf-82-320.jpg)

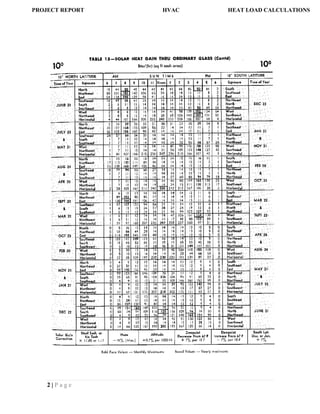

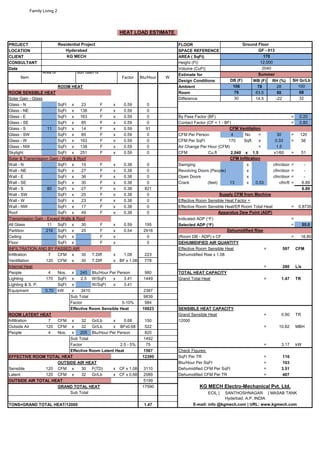

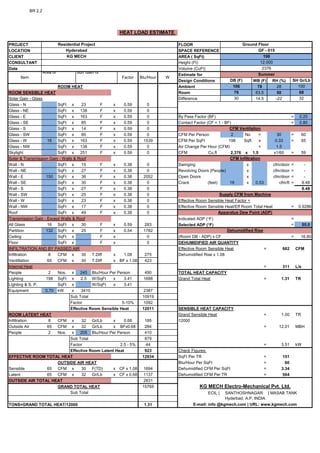

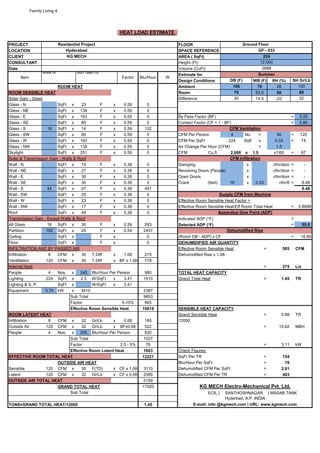

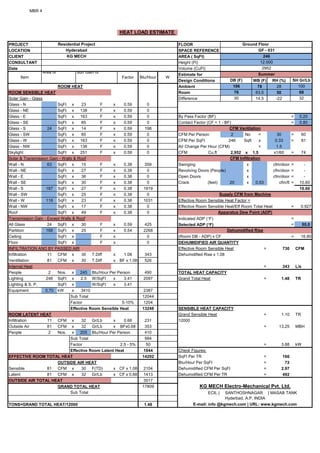

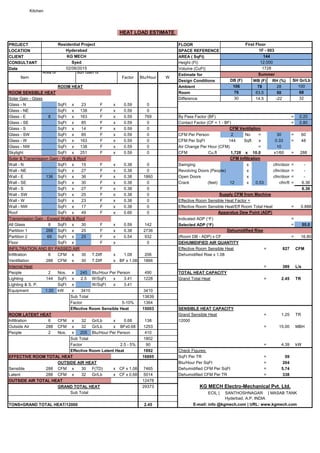

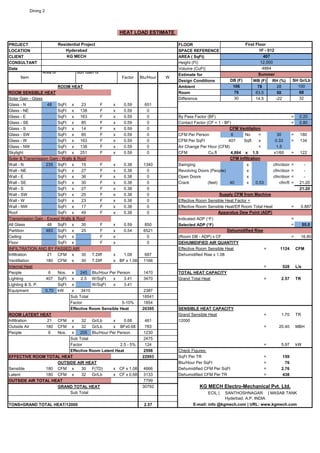

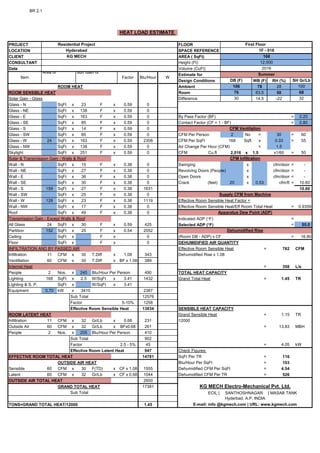

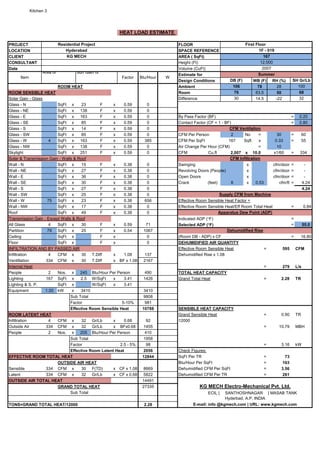

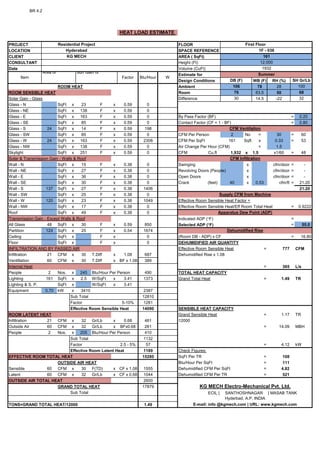

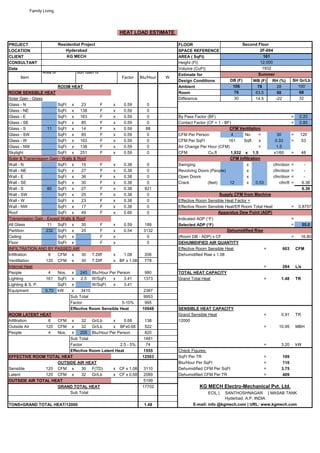

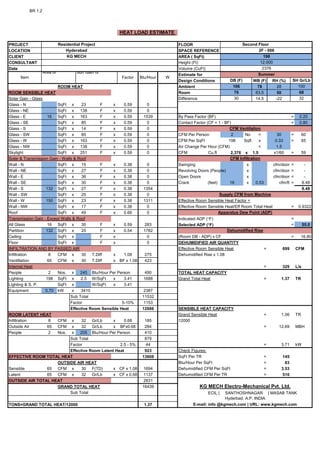

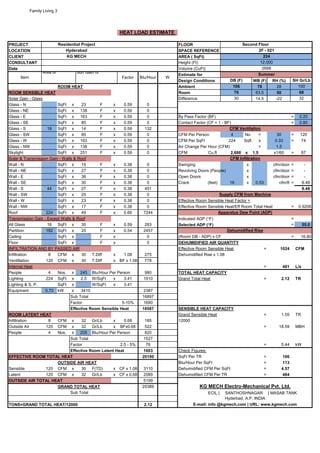

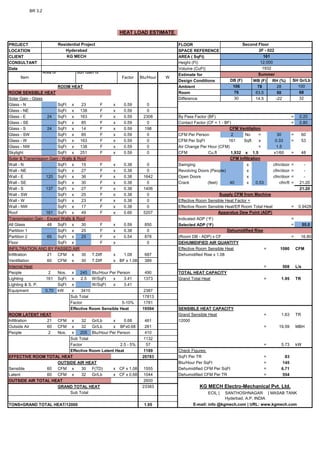

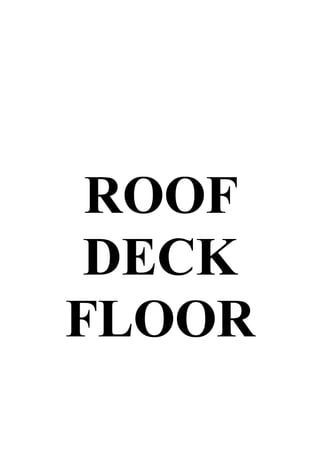

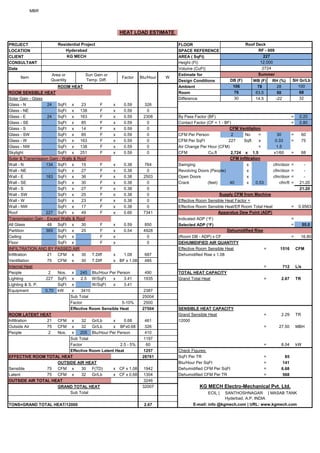

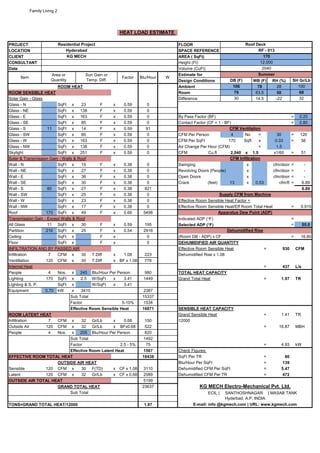

![PROJECT REPORT HVAC HEAT LOAD CALCULATIONS

P a g e 3 | 49

From Table – 21,

Weight of 8 inch Wall [Solid Brick (Face & Common)] is 87 lb/sqft. But we had

taken as 100 lb/sqft.

Weight of 6 inch Roof [Medium Concrete] is 40 lb/sqft

iii. Peak Timing

Correction Factor depends on

i. Daily Range (o

F) = Outside DBT – Outside WBT = 106 – 78 = 28 o

F

ii. Difference between Outside & Inside DBT = 106 – 76 = 30 o

F

Temperature Difference Table for 8 inch Wall:

S.No. Direction Equivalent

Temp.

Correction

Factor

Temperature

Difference ( ETD +

CF) [oF]

1 North 4 11 15

2 Northeast 16 11 27

3 East 25 11 36

4 Southeast 19 11 30

5 South 16 11 27

6 Southwest 14 11 25

7 West 12 11 23

8 Northwest 6 11 17

Temperature Difference Table for 6 inch Roof:

S.No. Direction Equivalent

Temp.

Correction

Factor

Temperature

Difference

1 Exposed to Sun 38 11 49

Temperature Difference for Partition Wall is given as

= (Outside DBT – Inside DBT) – 5 o

F](https://image.slidesharecdn.com/entrylevelhvac-221031083613-17d05f8b/85/ENTRY-LEVEL-HVAC-pdf-83-320.jpg)

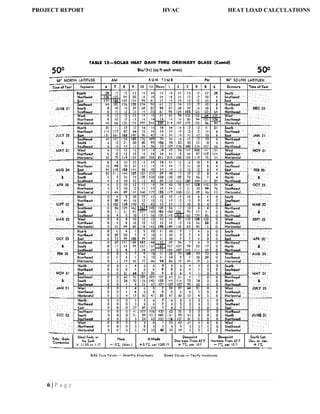

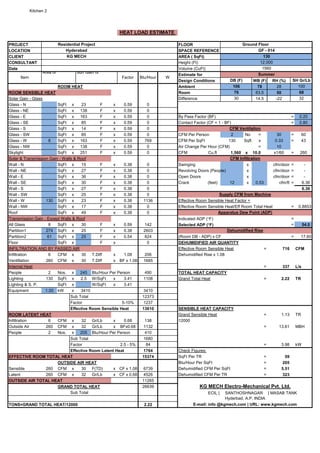

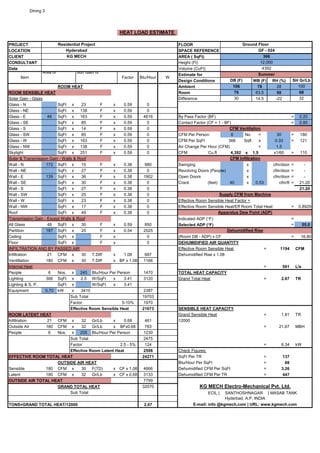

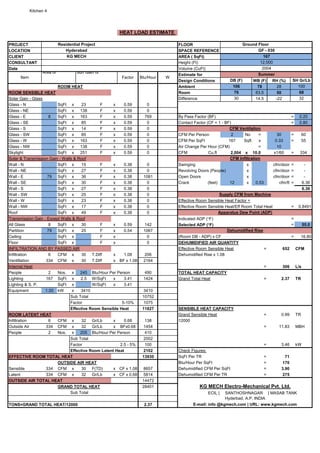

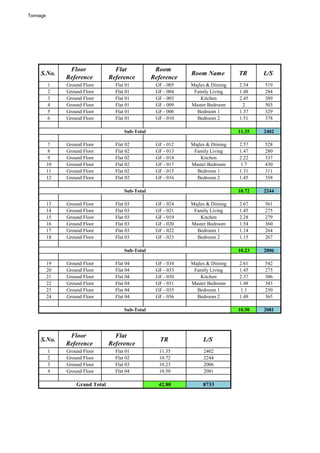

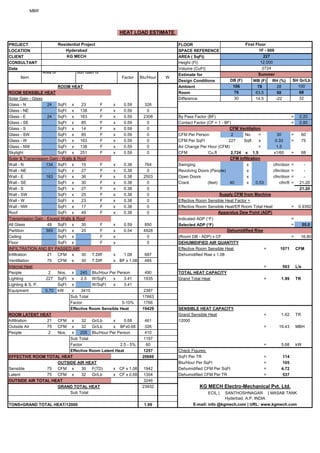

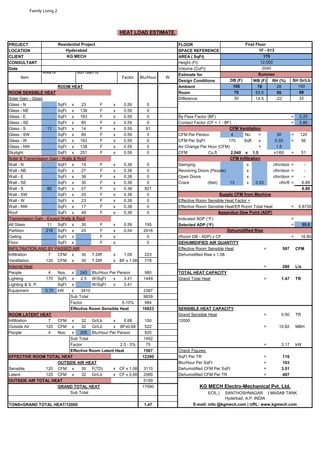

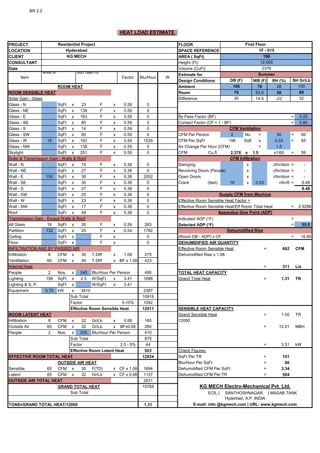

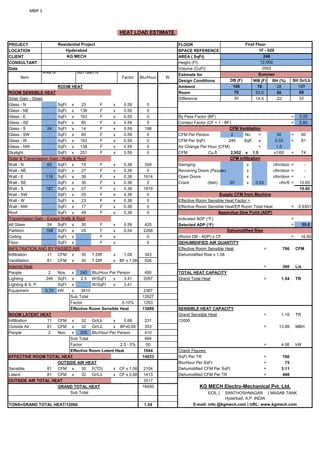

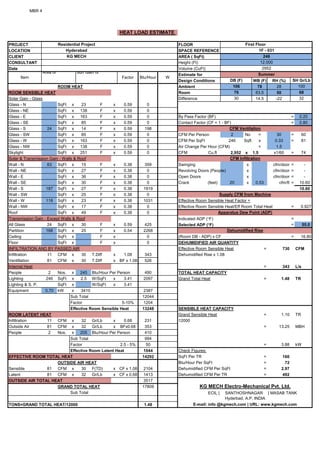

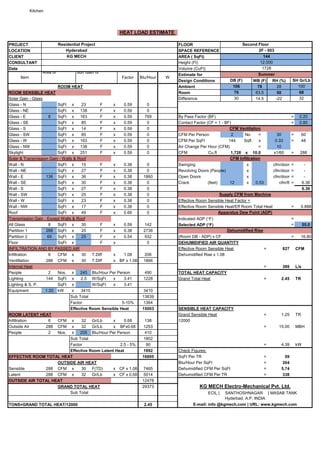

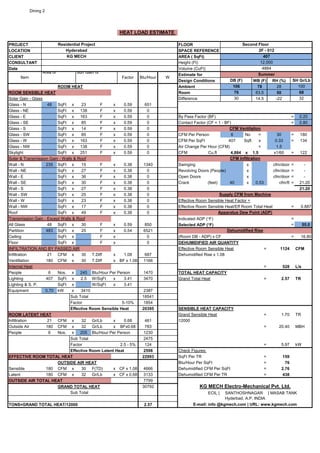

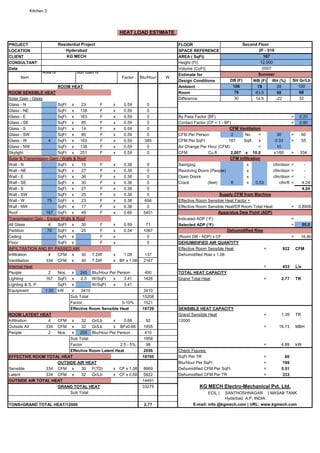

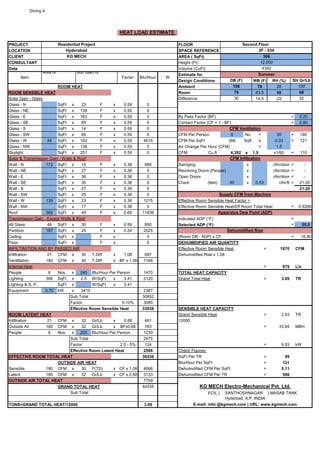

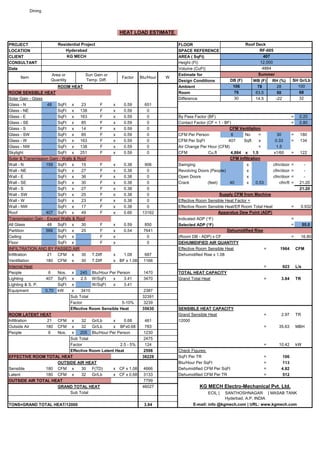

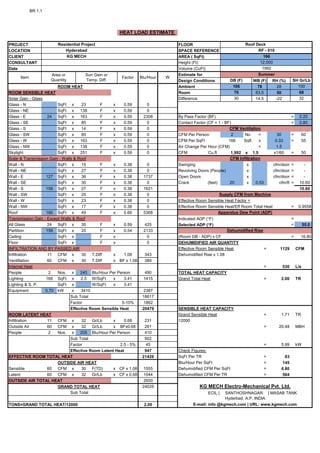

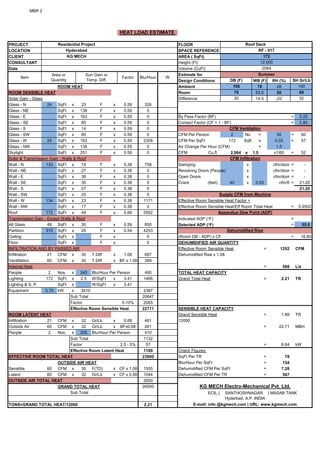

![PROJECT REPORT HVAC HEAT LOAD CALCULATIONS

P a g e 14 | 49

A = 1680 Sqft

U = 0.54 (4 inch wall)

Temp. Diff = [(106 – 76) – 5] = 25 o

F

Q = U * A * Temp. Diff

Q = 0.54 x 1680 x 25

Q = 22680 Btu/hr

Infiltration & By-Passed Air:-

Ventilation:

Ventilation = CFM Ventilation x Temp. Diff x B.F x 1.08

CFM Ventilation:-

By People:

= No. of People x CFM/Person (Refer Table – 45)

= 600 x 30 = 18000 CFM

By Area:

= Area of Surface x CFM/Sqft (Refer Table – 45)

= 15000 x 0.33 = 4950 CFM

By Volume:

ACH = 4

= Volume x ACH (Refer Table)

= 225000 x 4 x 1/60

= 15000 CFM

Therefore, CFM Ventilation = 18000 CFM (We have to take maximum value of ventilation)

Ventilation = CFM Ventilation x Temp. Diff x B.F x 1.08

= 18000 x 30 x 0.2 x 1.08

= 116640 Btu/hr

Infiltration:

Infiltration = CFM Infiltration x Temp. Diff x 1.08

CFM Infiltration:-](https://image.slidesharecdn.com/entrylevelhvac-221031083613-17d05f8b/85/ENTRY-LEVEL-HVAC-pdf-94-320.jpg)

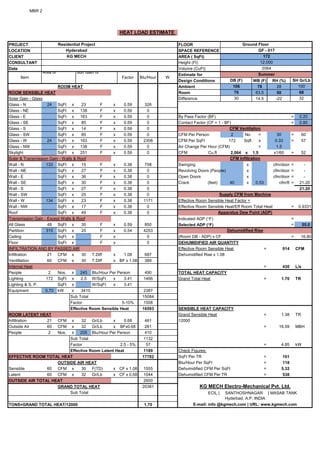

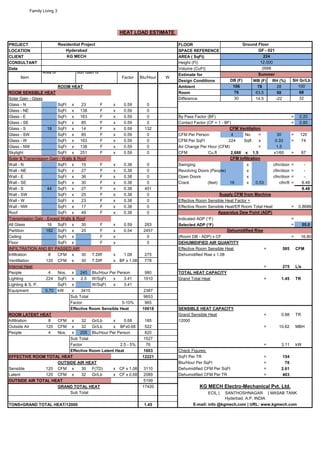

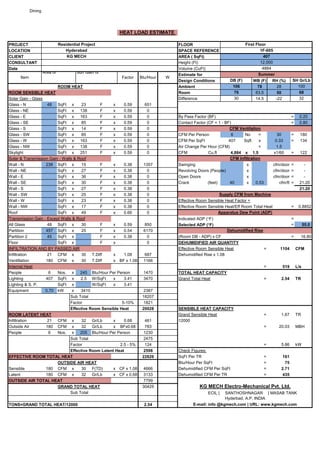

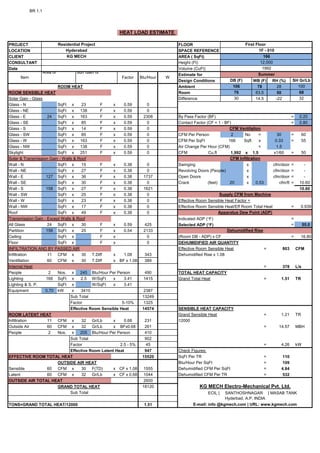

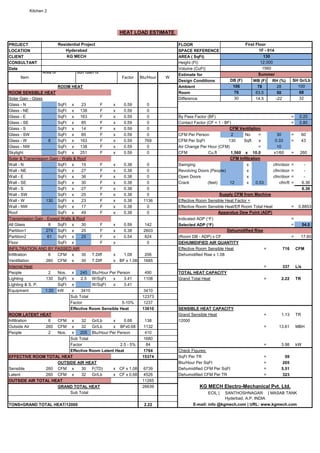

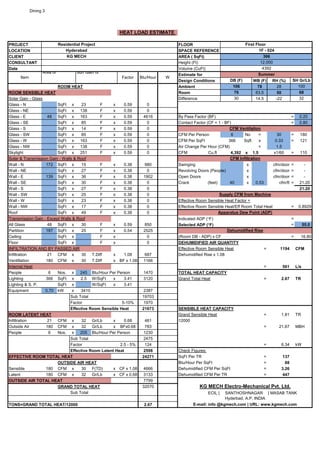

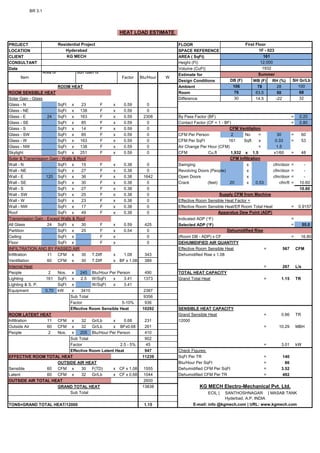

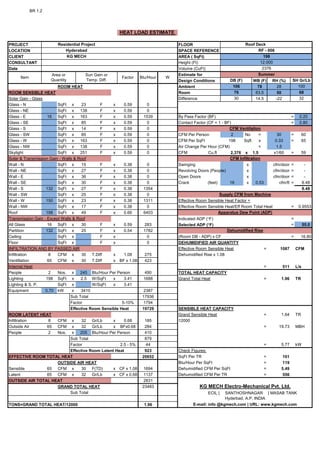

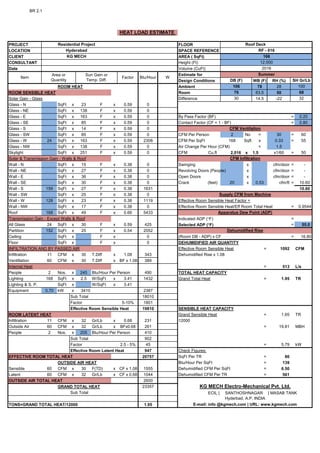

![PROJECT REPORT HVAC HEAT LOAD CALCULATIONS

P a g e 15 | 49

Crack Method:

= Length of Crack x CFM/Ft of Crack (Refer Table – 44b)

= (252 + 18) x 0.53

= 270 x 0.53

= 143 CFM

Infiltration = 143 x 30 x 1.08

= 4636 Btu/hr

Internal Heat:-

People:

= No. of People x Btu/hr per Person (Sensible) [Refer Table – 48]

= 600 x 245 = 147000 Btu/hr

Lighting:

= Area x W/Sqft x 3.41 = 15000 x 3 x 3.41

= 153450 Btu/hr

Equipment:

= KW x 3.41 x 1000 = 0.7 x 3.41 x 1000

= 2387 Btu/hr

ROOM SENSIBLE HEAT (Sub Total) = 1026041 Btu/hr

Safety Factor [10%] = 102604 Btu/hr (10% of Room Sensible Heat Sub Total)

EFFECTIVE ROOM SENSIBLE HEAT = 1026041 + 102604

ERSH = 1128645 Btu/hr

ROOM LATENT HEAT:

Ventilation:

= CFM Ventilation x Diff in SH x B.F x 0.68

= 18000 x (100 – 68) x 0.2 x 0.68

= 78336 Btu/hr

Infiltration:

= CFM Infiltration x Diff in SH x 0.68](https://image.slidesharecdn.com/entrylevelhvac-221031083613-17d05f8b/85/ENTRY-LEVEL-HVAC-pdf-95-320.jpg)

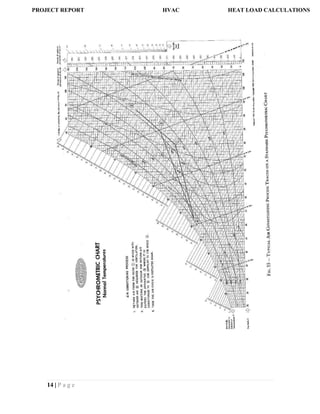

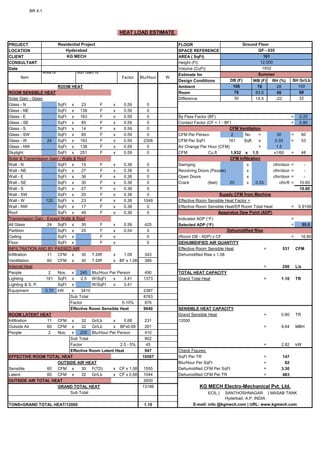

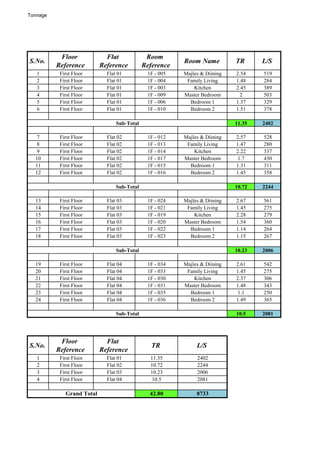

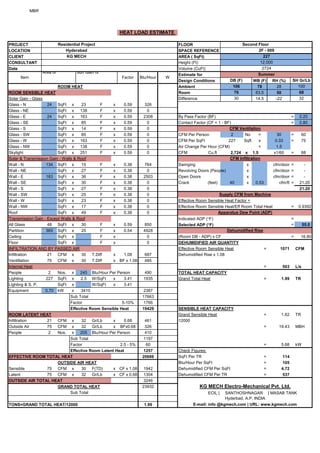

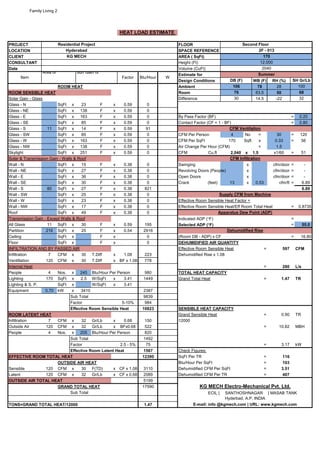

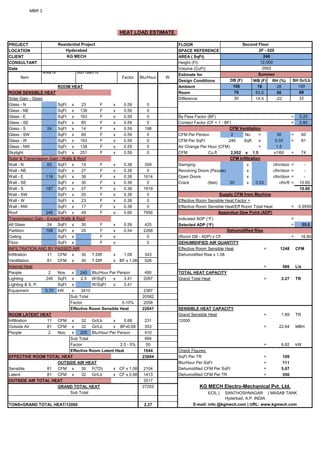

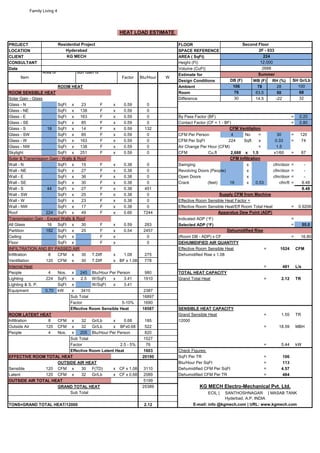

![PROJECT REPORT HVAC HEAT LOAD CALCULATIONS

P a g e 16 | 49

= 143 x (100 – 68) x 0.68

= 3114 Btu/hr

People:

= No. of People x Btu/hr per Person (Latent) [Refer Table – 48]

= 600 x 205

= 123000 Btu/hr

ROOM LATENT HEAT (Sub Total) = 204450 Btu/hr

Safety Factor [5%] = 10222 Btu/hr

EFFECTIVE ROOM LATENT HEAT = 204450 + 10222

ERLH = 214672 Btu/hr

EFFECTIVE ROOM TOTAL HEAT = ERSH + ERLH

= 1128645 + 214672

= 1343317 Btu/hr

OUTSIDE AIR HEAT (OAH):

Sensible = CFM Ventilation x Temp. Diff x C.F x 1.08

= 18000 x 30 x 0.8 x 1.08 = 466560 Btu/hr

Latent = CFM Ventilation x Diff. in SH x C.F x 0.68

= 18000 x 32 x 0.8 x 0.68

= 313344 Btu/hr

OUTSIDE AIR TOTAL HEAT = SENSIBLE + LATENT

= 466560 + 313344

= 779904 Btu/hr

GRAND TOTAL HEAT = ERSH + ERLH + OAH

= 1128645 + 214672 + 779904

GTH = 2123221 Btu/hr

1 TR = 12000 Btu/hr

TR = GTH / 12000

TR = 2123221 / 12000](https://image.slidesharecdn.com/entrylevelhvac-221031083613-17d05f8b/85/ENTRY-LEVEL-HVAC-pdf-96-320.jpg)

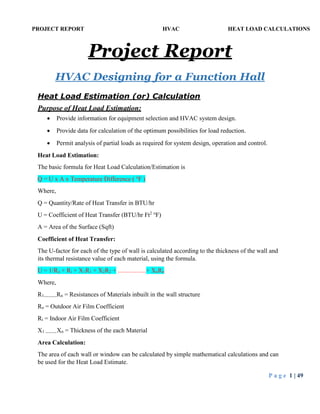

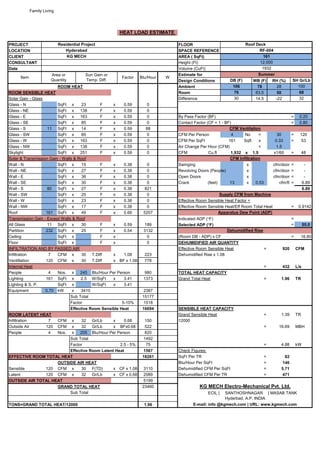

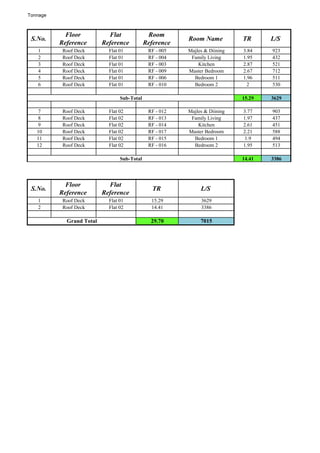

![PROJECT REPORT HVAC HEAT LOAD CALCULATIONS

R-VALUE FOR TYPICAL BUILDING MATERIALS

THERMAL RESISTANCE h ft2 oF / Btu [R / inch]

Concrete 0.10

Stone 0.05...0.10

Brick 0.10...0.35

Hardwood 0.90

Softwood / plywood 1.25

Particle board 0.85...1.85

Insulating board 2.30...2.60

Sidings 0.80...1.00

Asphalt shingles 0.44

Wood shingles 0.94

Built-up roofing 0.70...0.90

Rock wool 3.20...3.70

Mineral wool or fiber batt 2.90

Cellulose 3.20...3.70

Lightweight aggregate concrete 1.00...2.00

Cement board 1.50...2.30

Stucco / plaster 0.20

Gypsum / plaster board 0.90

Fiberglas 3.16

Fiberboard 3.45

Polystyrene extruded 5.00...5.40

Polystyrene expanded 3.85...4.35

Polyurethane foam 5.80...7.70

Building paper / felt 0.06

Cork 2.00

Ceramic tile 0.15

Vinyl / linoleum / rubber tile 0.64

Synthetic carpet (level loop) 3.50...5.90

Synthetic carpet (plush) 2.40...4.50

Wool carpet 4.50

Fiber / hair / jute cushion 3.88

Flat rubber cushion 2.72

Rippled rubber cushion 1.82

Prime urethane cushion 4.44

Bonded urethane cushion 3.96

Solid wood door 1.56

Single glass window 0.89

Insulating double glass 1.89

Energy plus double glass 4.50

THERMAL TRANSMISSION Imperial: 1 = Btu/h ft2 oF

R

Metric: 1 x 5.678 = W/m2 oC

R](https://image.slidesharecdn.com/entrylevelhvac-221031083613-17d05f8b/85/ENTRY-LEVEL-HVAC-pdf-99-320.jpg)

![R-VALUE FOR TYPICAL BUILDING MATERIALS

THERMAL TRANSMISSION Imperial: 1 = Btu/h ft2 oF

R

Metric: 1 x 5.678 = W/m2 oC

R

THERMAL RESISTANCE h ft2 o

F / Btu [R / inch]

Concrete 0.10

Stone 0.05...0.10

Brick 0.10...0.35

Hardwood 0.90

Softwood / plywood 1.25

Particle board 0.85...1.85

Insulating board 2.30...2.60

Sidings 0.80...1.00

Asphalt shingles 0.44

Wood shingles 0.94

Built-up roofing 0.70...0.90

Rock wool 3.20...3.70

Mineral wool or fiber batt 2.90

Cellulose 3.20...3.70

Lightweight aggregate concrete 1.00...2.00

Cement board 1.50...2.30

Stucco / plaster 0.20

Gypsum / plaster board 0.90

Fiberglas 3.16

Fiberboard 3.45

Polystyrene extruded 5.00...5.40

Polystyrene expanded 3.85...4.35

Polyurethane foam 5.80...7.70

Building paper / felt 0.06

Cork 2.00

Ceramic tile 0.15

Vinyl / linoleum / rubber tile 0.64

Synthetic carpet (level loop) 3.50...5.90

Synthetic carpet (plush) 2.40...4.50

Wool carpet 4.50

Fiber / hair / jute cushion 3.88

Flat rubber cushion 2.72

Rippled rubber cushion 1.82

Prime urethane cushion 4.44

Bonded urethane cushion 3.96

Solid wood door 1.56

Single glass window 0.89

Insulating double glass 1.89

Energy plus double glass 4.50](https://image.slidesharecdn.com/entrylevelhvac-221031083613-17d05f8b/85/ENTRY-LEVEL-HVAC-pdf-223-320.jpg)