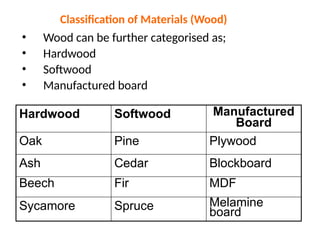

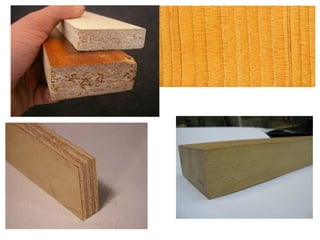

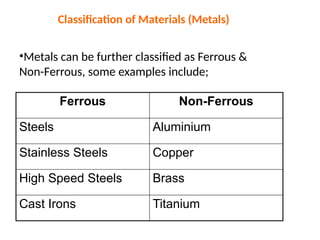

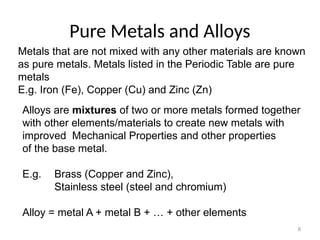

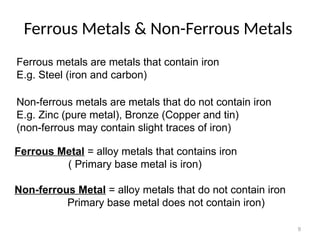

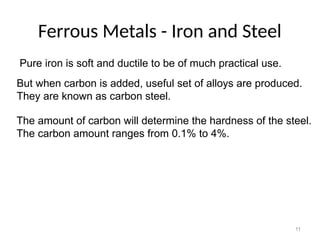

The document provides an overview of the classification of engineering materials, detailing four main categories: metals and alloys, ceramics, polymers, and composites. It elaborates on the properties and classifications of metals, including ferrous and non-ferrous types, as well as various types of steel. Additionally, it discusses ceramics, polymers, composite materials, and smart materials, highlighting their characteristics and applications in engineering and design.

![1.1 CLASSIFICATION OF ENGINEERING

MATERIALS

METALS AND ALLOYS

These are inorganic materials composed of one or

more metallic elements

Characteristics

▪ They usually have a crystalline structure and are good

thermal and electrical conductors

▪ Many metals have high strength and high elastic moduli

[changes its shape only slightly under elastic loads (e.g. diamond))]

▪ They maintain their good strength at high and low

temperatures.](https://image.slidesharecdn.com/engineeringmaterialsandtheirproperties-240819173341-4b85b21f/85/Engineering-Materials-and-their-properties-pptx-4-320.jpg)

![16

Cast Iron

Contains 2%-4% of carbon

Very hard and brittle

Strong under compression

Suitable for casting [can be poured at a relatively

low temperature]

Examples are:

Engine block, engineer vices, machine parts](https://image.slidesharecdn.com/engineeringmaterialsandtheirproperties-240819173341-4b85b21f/85/Engineering-Materials-and-their-properties-pptx-16-320.jpg)