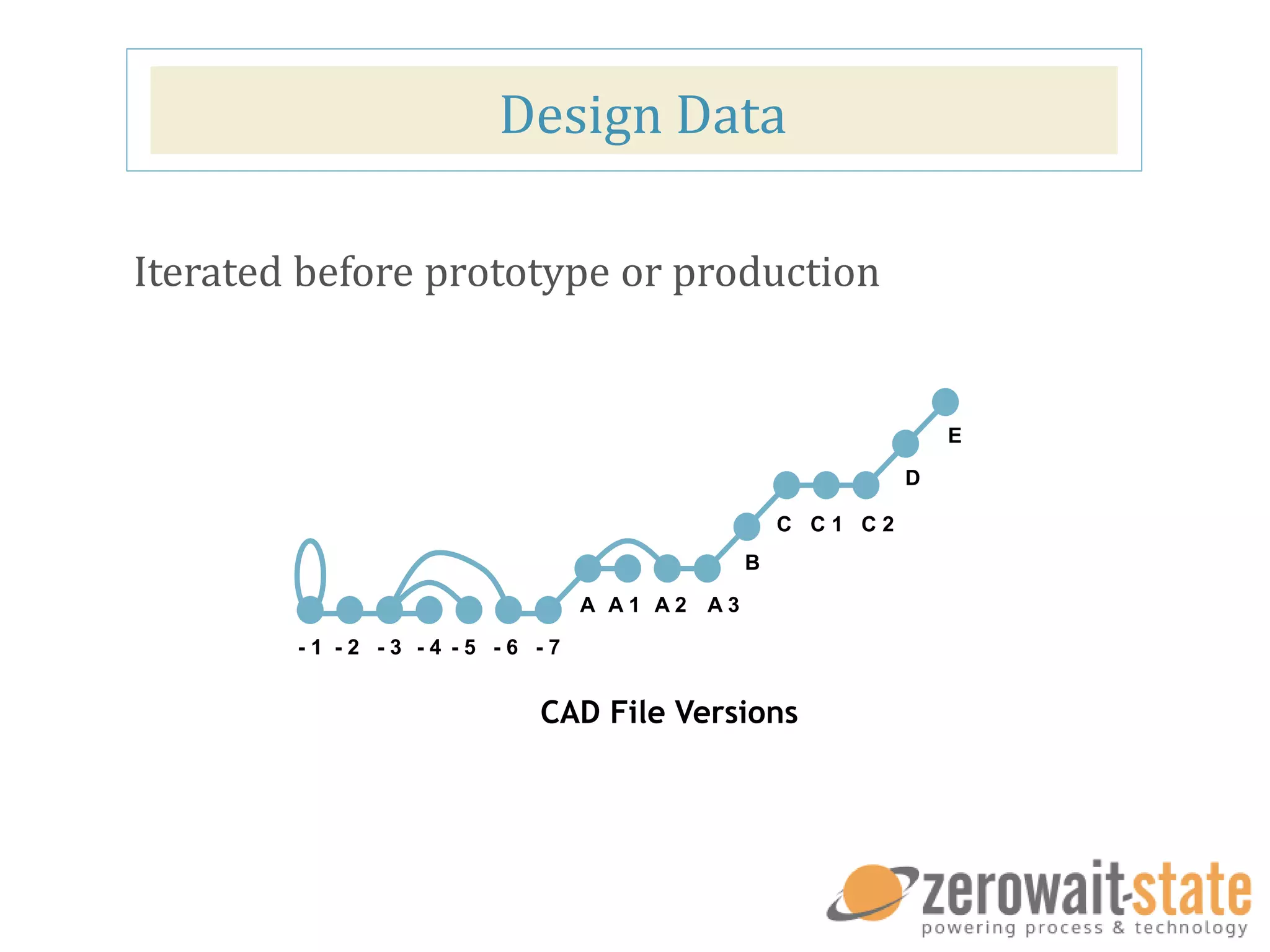

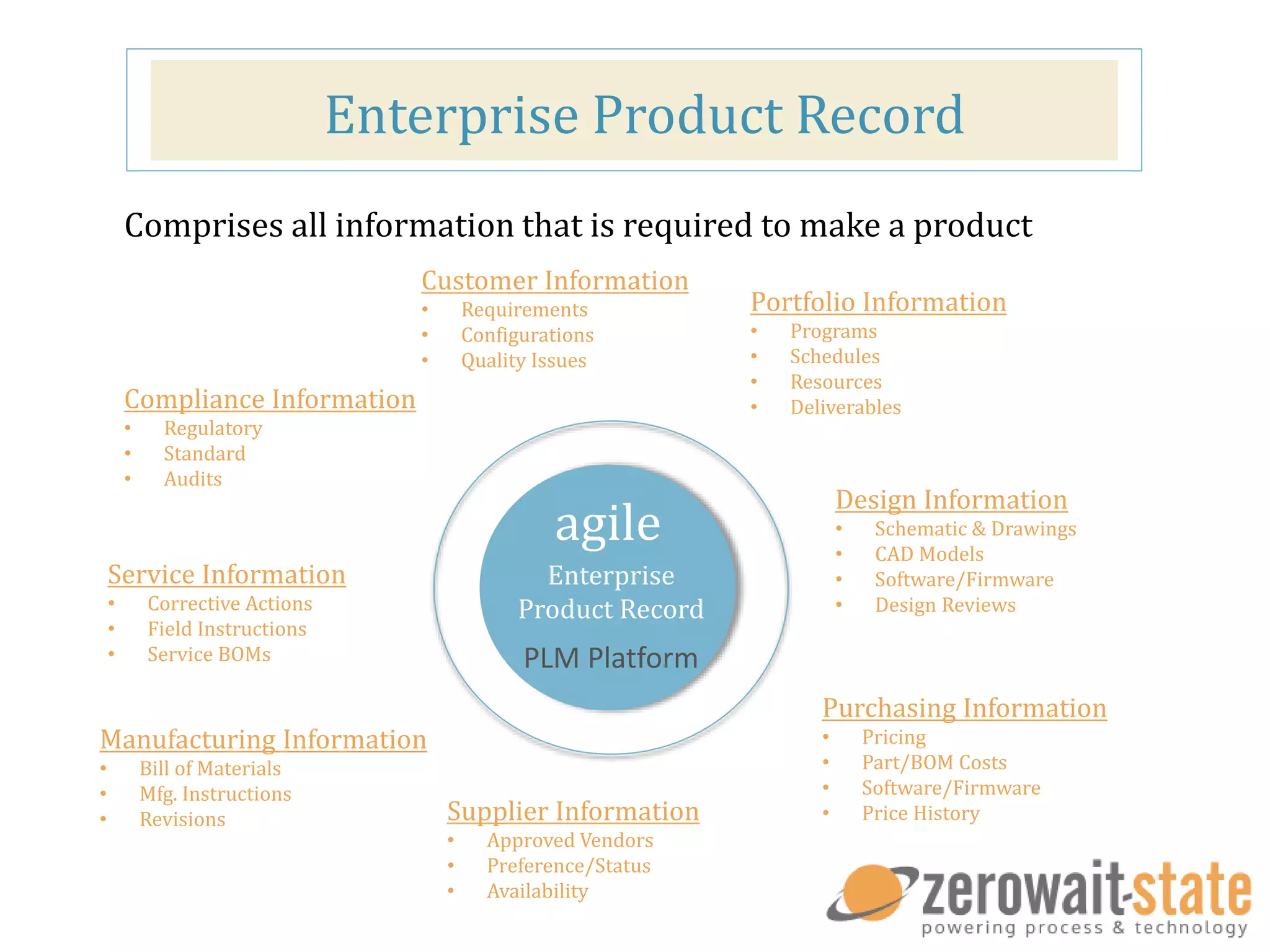

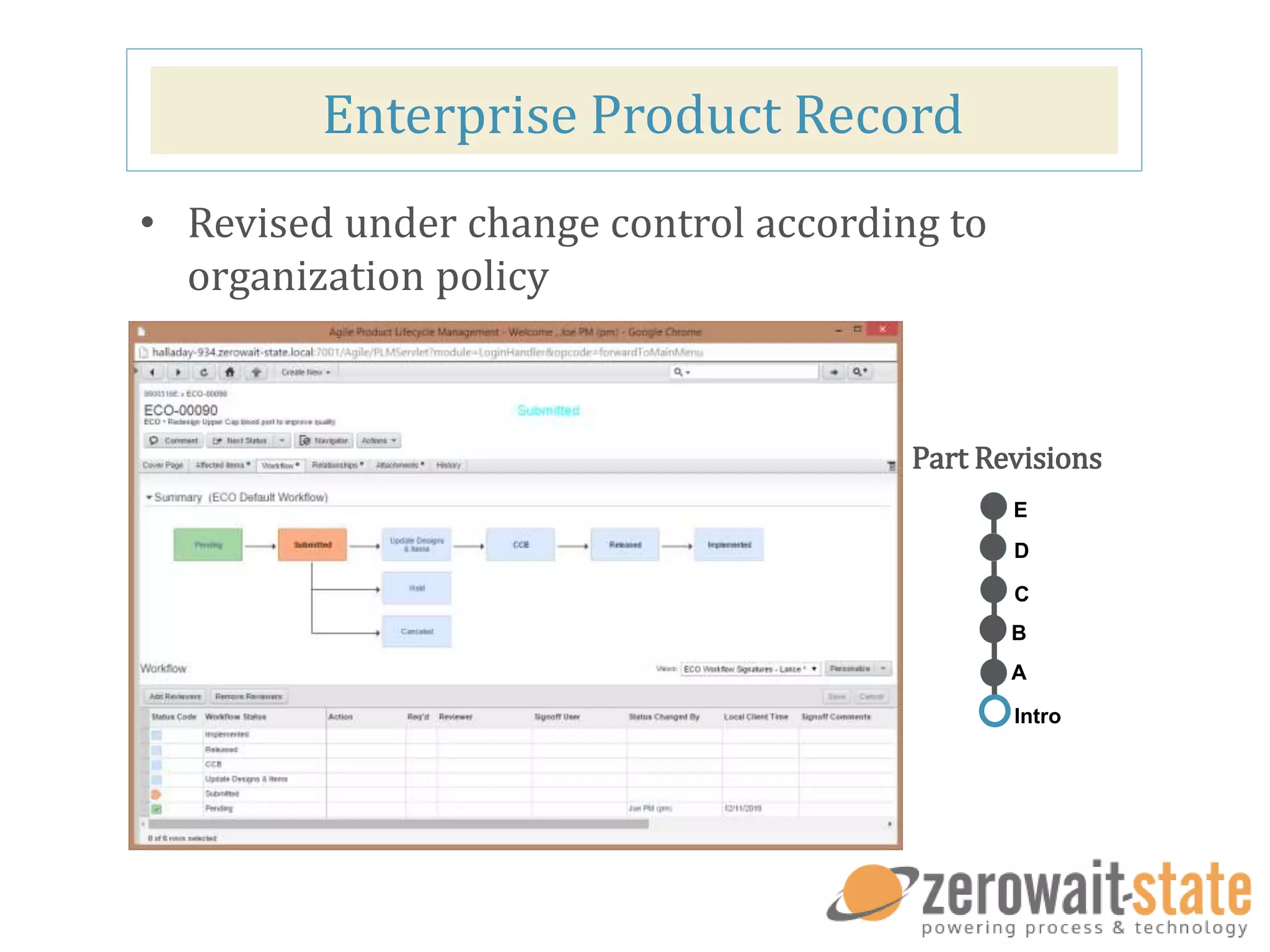

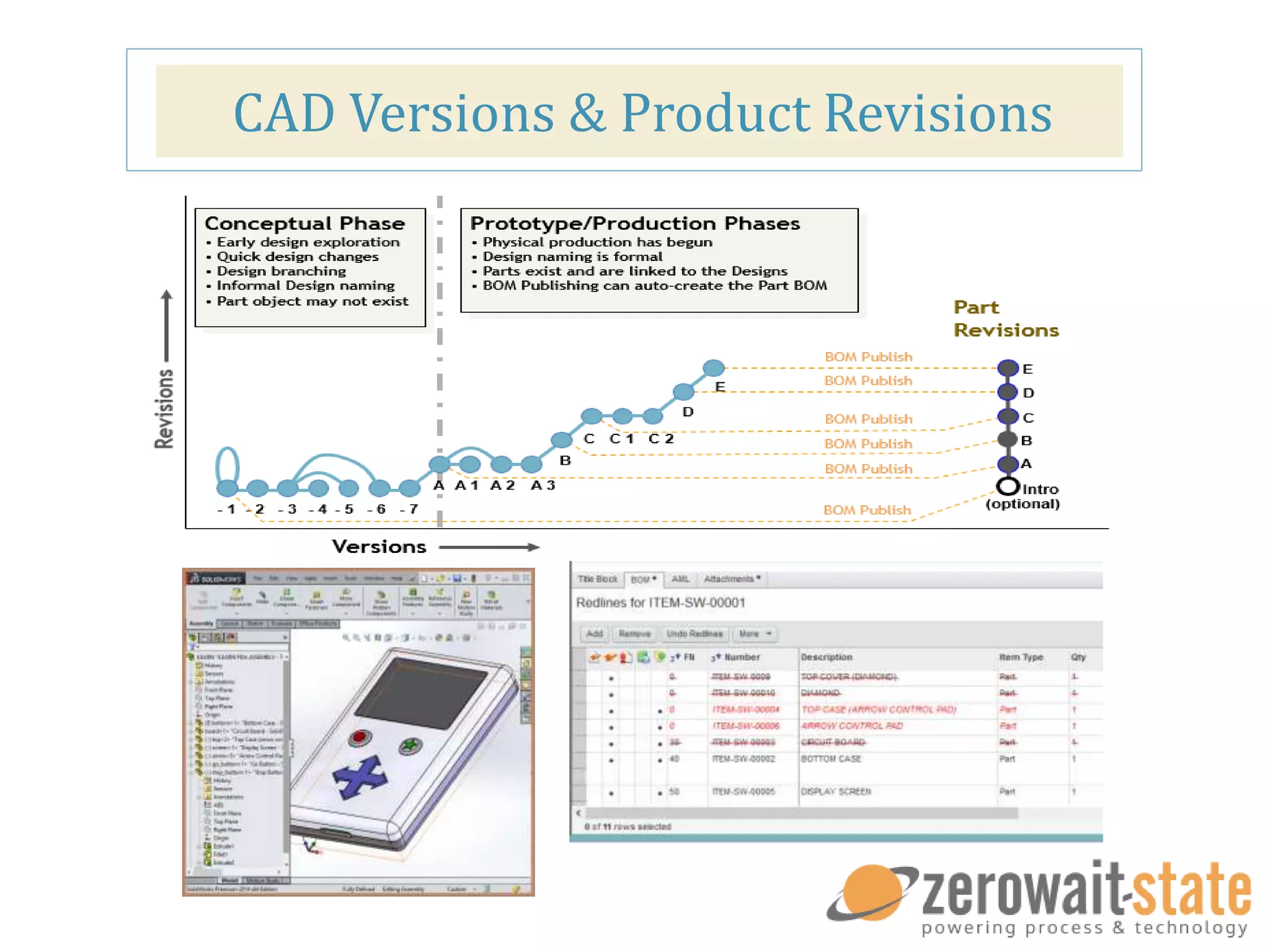

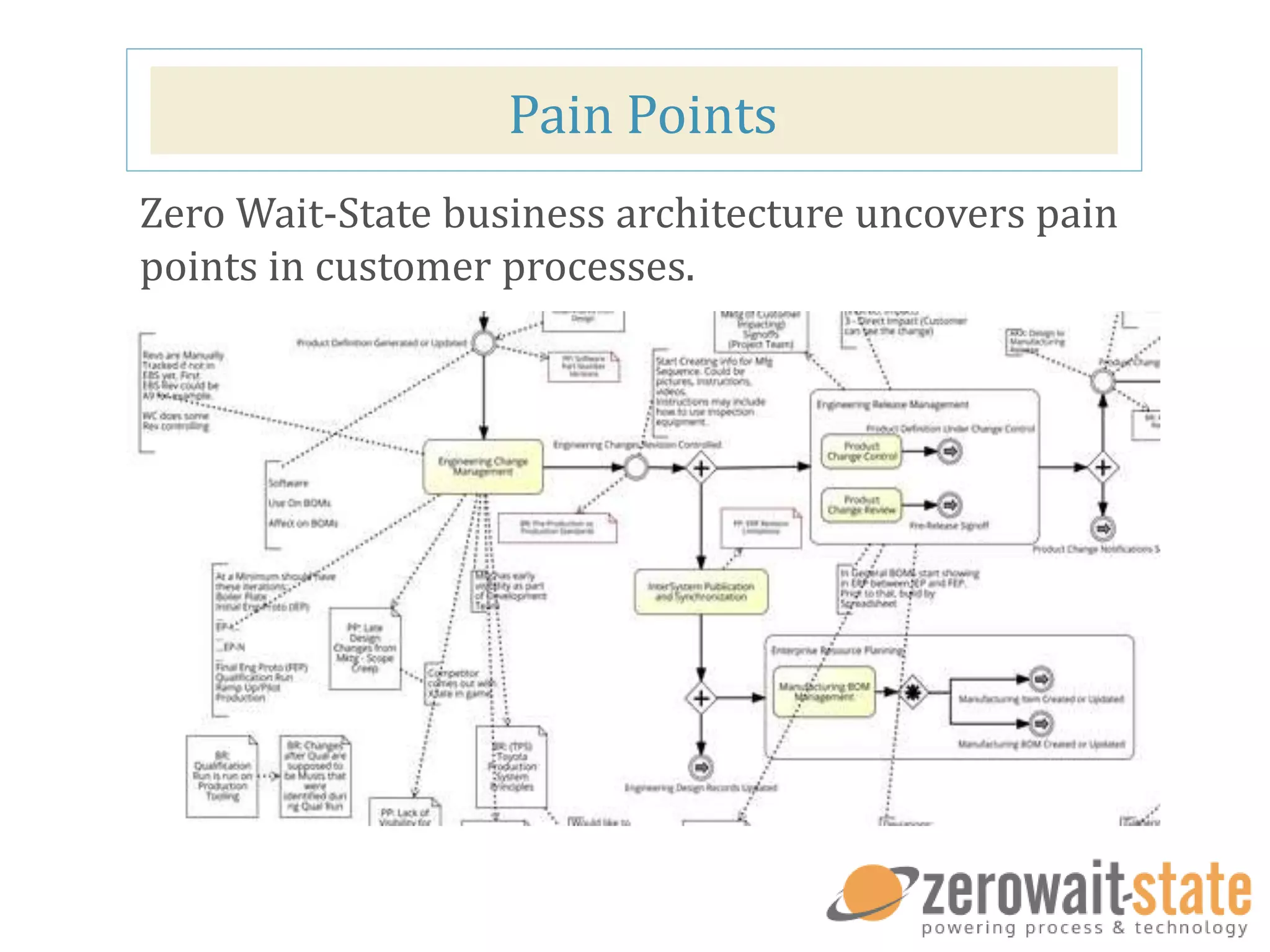

The document discusses managing engineering data through Product Lifecycle Management (PLM) strategies, presented by Mike Halladay and Dennis Walker from Zero Wait-State. It outlines the challenges companies face in information accuracy, process sequencing, and visibility, while offering solutions to maximize value, such as automated processes and enhanced data integration. The session emphasizes the importance of collaboration between engineering and enterprise teams to improve product design and management.