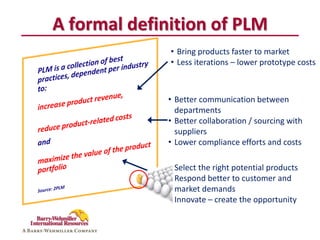

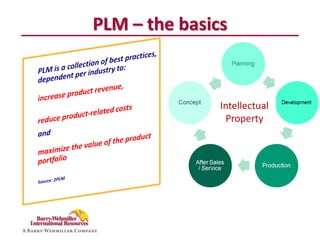

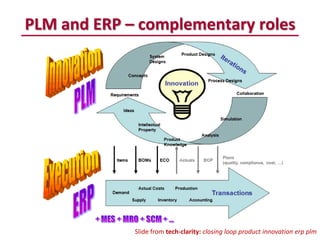

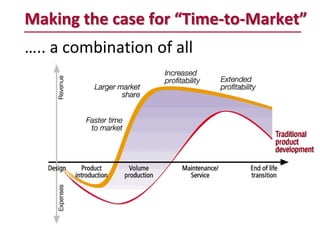

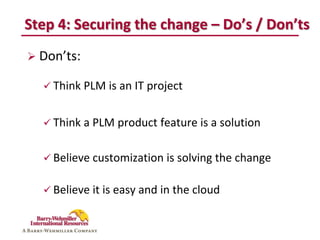

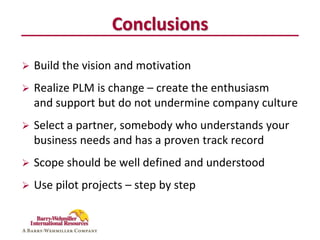

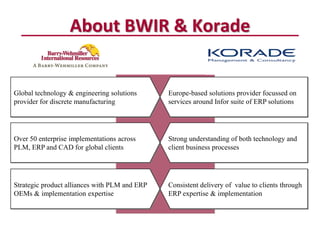

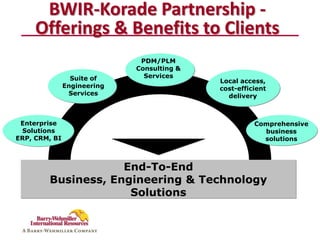

The document presents a presentation by Marcel Croonen and Jos Voskuil on Product Lifecycle Management (PLM), addressing its value, characteristics, and the steps needed for successful implementation. Jos Voskuil shares his experiences and insights into PLM's benefits, such as innovation, efficiency, quality, and improved time-to-market, while emphasizing the necessity of executive sponsorship and stakeholder involvement in the process. Additionally, the document briefly describes the BWIR-Korade partnership and its offerings in the context of PLM and ERP solutions.