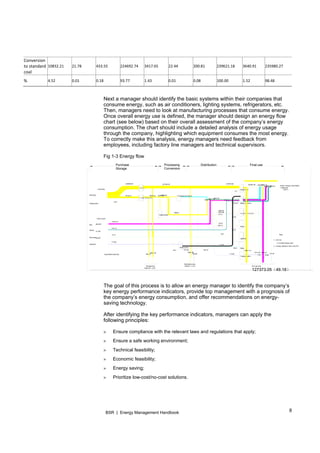

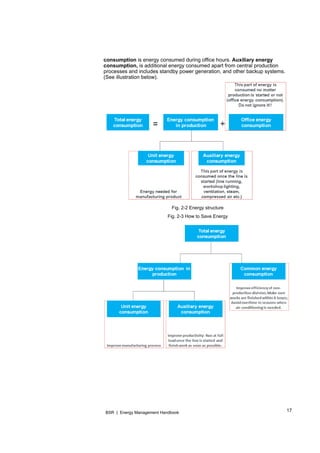

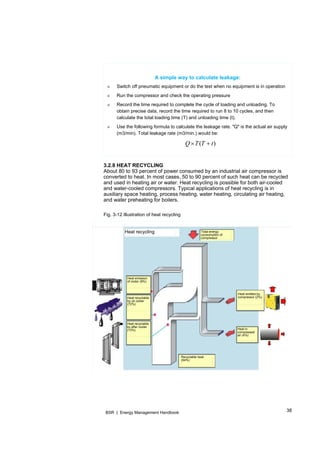

This document provides an overview and guidelines for establishing an energy management system according to Chinese and international standards. It discusses China's goal of reducing energy consumption and the benefits of energy management systems. Key points include establishing management commitment to energy efficiency, creating an energy policy, designating an energy manager, conducting energy audits and implementing energy saving practices for large energy systems. The document aims to help small and medium enterprises in China improve energy management and reduce costs.