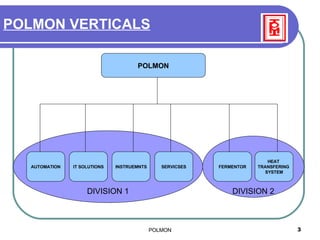

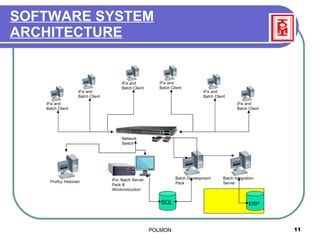

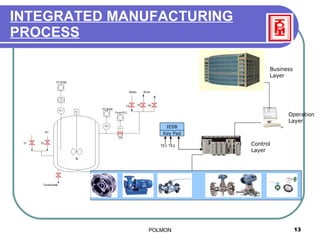

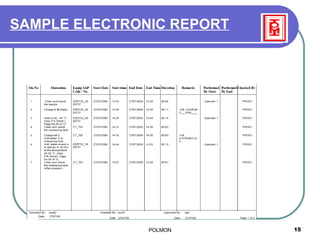

Polmon Instruments Pvt Ltd is an ISO 9001-2000 certified company that has provided instrumentation and process automation solutions to over 400 companies since 1987. The company believes in listening to customers to understand their challenges and addressing issues. Polmon offers automation, instrumentation, and IT solutions focused on regulatory standards like GAMP, CFR 21, and FDA requirements. It has developed electronic batch recording systems to improve productivity and meet compliance needs.