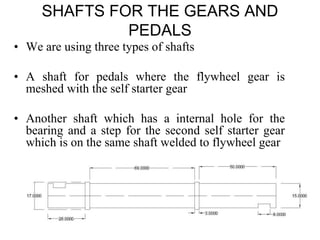

This document describes a student project to generate electricity from cycling. A bicycle was outfitted with gears connected to an alternator to produce electrical power from pedaling. The alternator generates 12V DC power that is stored in a battery. An inverter can then convert the DC power in the battery to 220V AC power for small household appliances. The project aims to allow people to power devices through exercise and reduce electricity bills. While successful in reaching high speeds, further adjustments are needed to output a full 12V for battery charging.