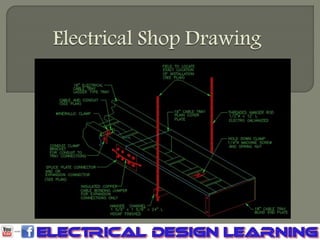

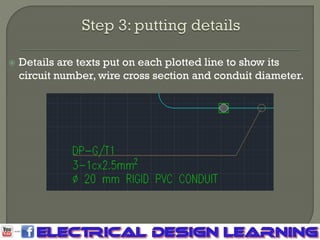

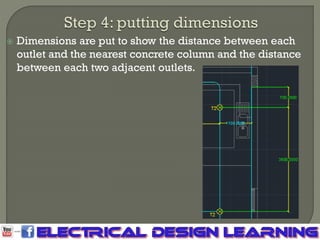

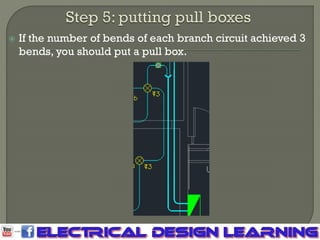

Shop drawings are detailed illustrations necessary for site engineers to accurately implement designs, differing from design drawings that outline general positions without specifics. The contractor is responsible for creating these drawings, with consultants approving or creating them in complex projects. The document outlines the steps for making shop drawings using AutoCAD 2015, including detailed processes for outlets, switches, circuits, and necessary dimensions.