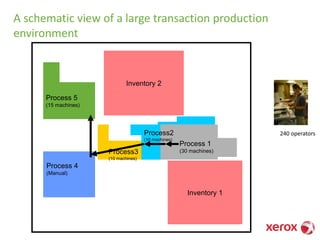

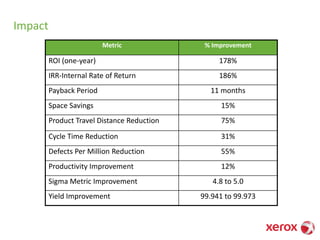

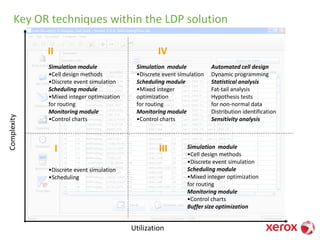

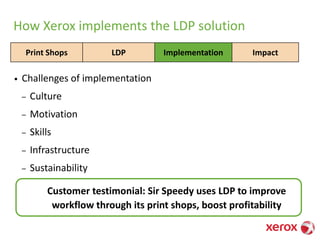

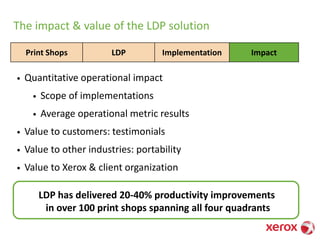

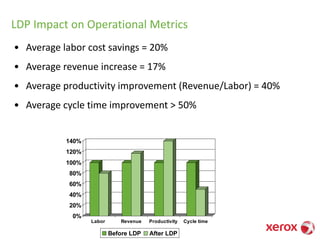

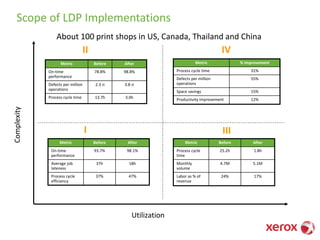

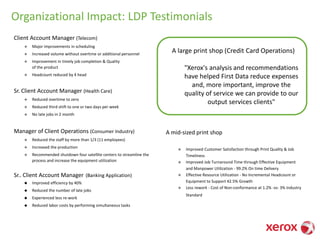

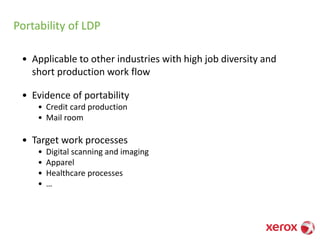

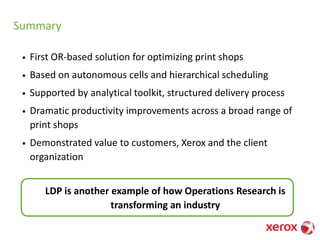

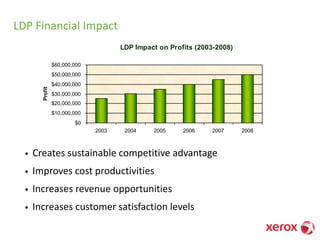

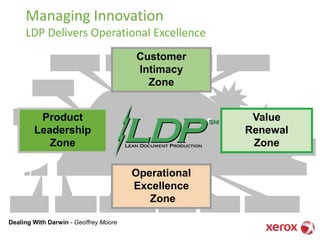

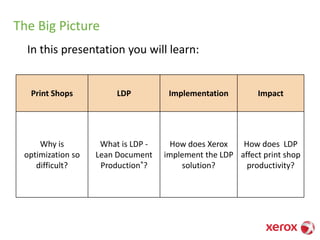

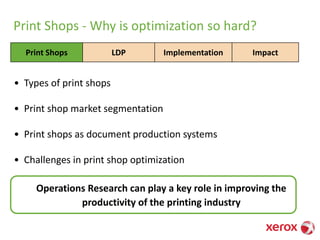

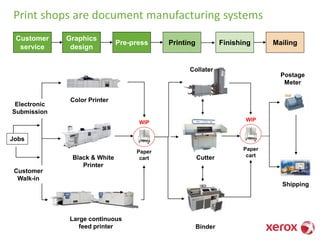

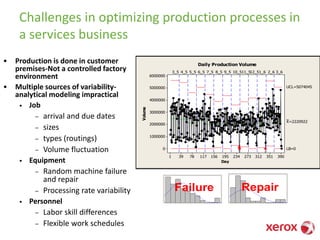

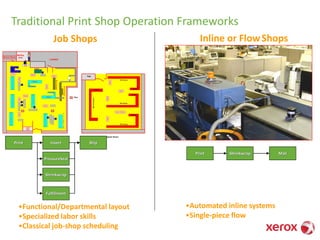

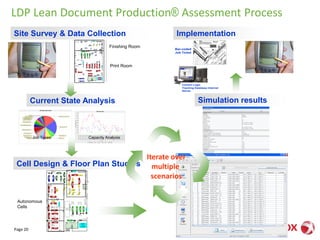

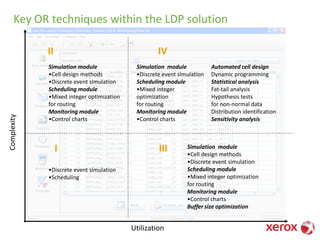

The document discusses the Lean Document Production® (LDP) implemented by Xerox to improve productivity in the printing industry, achieving over $200 million in productivity enhancements. LDP utilizes operations research methodologies to optimize print shop processes, resulting in significant operational improvements such as reduced cycle times and increased revenues. It highlights challenges in print shop optimization and presents quantitative impacts of LDP across various implementations in print shops.

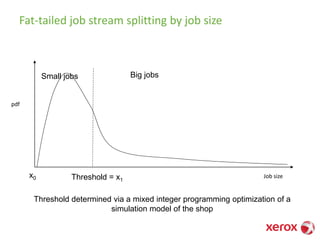

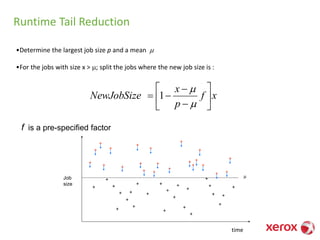

![Characterizing and analyzing very high variability using

fat-tailed distributions

Let X be a random variable with cdf F(x) = P[X≤ x] and complementary

cdf (ccdf) Fc(x) = P[X>x]. We say here that a distribution F(x) is fat-tailed

if

Fc (x) ~ cx-a 0<a<2 (1)

In the limit of x->∞ (2)

α

dlogx

(x)dLogF

lim

x

c

-=

→

Heavy-tailed distribution determination

-6

-5

-4

-3

-2

-1

0

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Ln(JobSize)

Ln(CCDF)

Heavy-tailed distribution

determination

Fat-tailed distribution determination](https://image.slidesharecdn.com/edelmancompetitionpresentationslides-190722023358/85/Edelman-competition-presentation-slides-23-320.jpg)