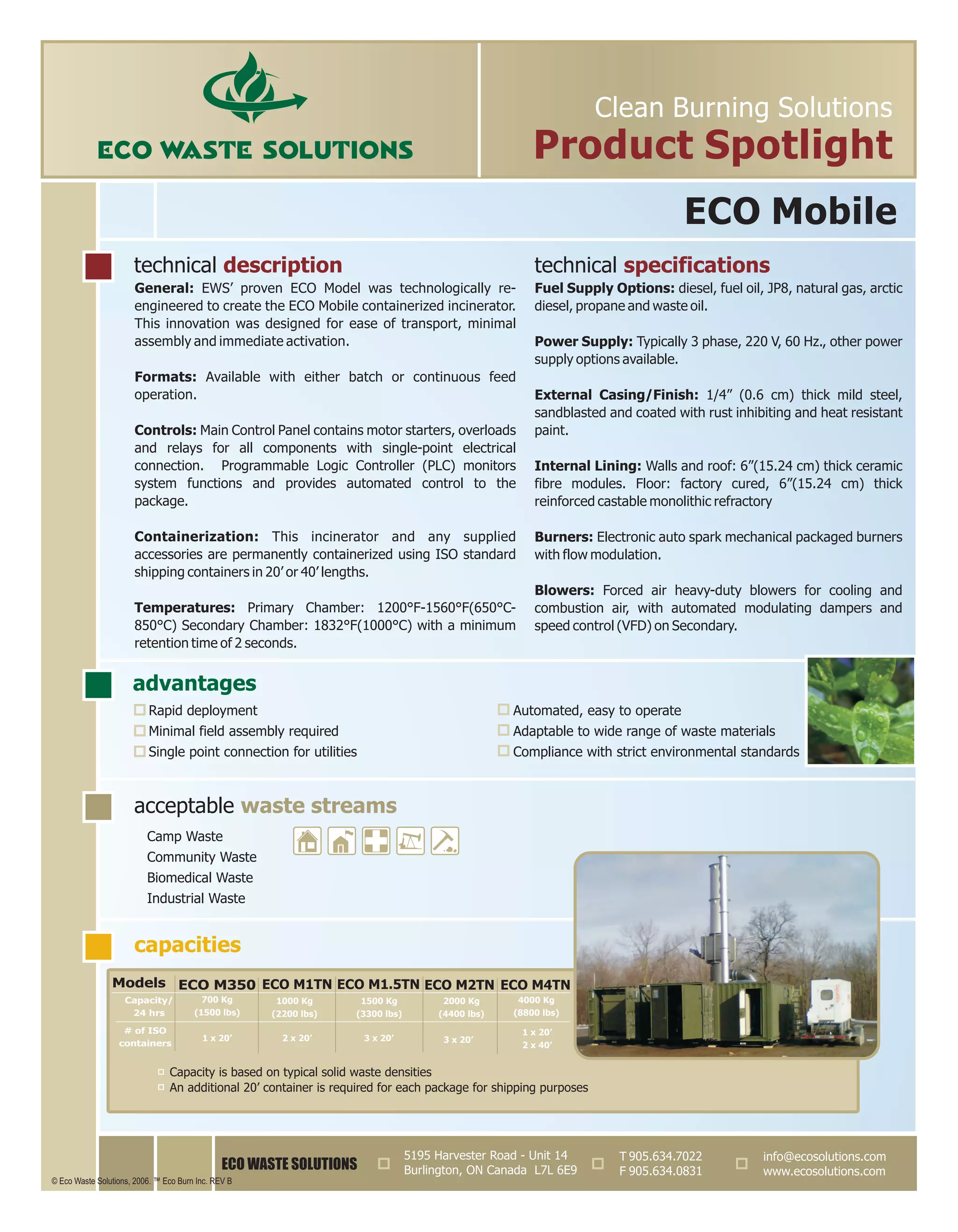

The ECO Mobile containerized incinerator is designed for ease of transport, minimal assembly, and immediate activation. It comes in batch or continuous feed formats and can be powered by diesel, fuel oil, natural gas, or electricity. The incinerator and any accessories are permanently enclosed in ISO shipping containers for transport. It features automated controls, high temperature combustion chambers, and the ability to handle a wide range of waste materials while meeting environmental standards.