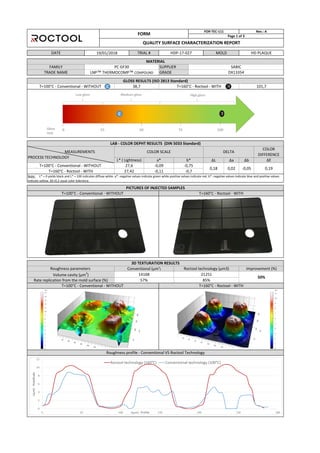

1) Roctool technology improves surface quality by removing weld lines, sink marks, and glass fibers from the surface compared to conventional molding. It allows for a darker color with a perfect surface finish.

2) Textured areas show Roctool technology increases replication rate by up to 85% and significantly reduces roughness.

3) Gloss value increases up to 163% with Roctool technology due to elimination of glass fibers at the surface.