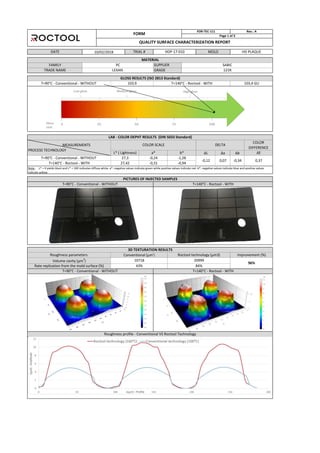

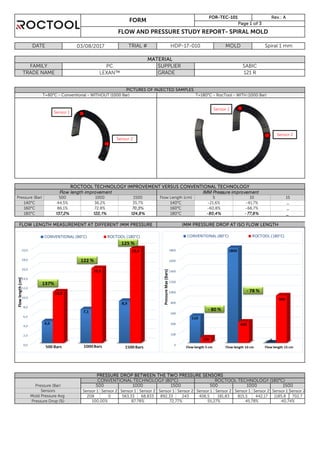

1) Testing was conducted using a spiral mold to compare the flow and pressure characteristics of conventional injection molding versus Roctool technology.

2) With Roctool technology (180°C mold temperature), flow length was improved by up to 137% and injection pressure drop was reduced by up to 66% compared to conventional molding (80°C).

3) Pressure drop between sensors in the cavity was reduced by up to 48% when using Roctool technology with a 1.5mm thick spiral versus conventional molding.