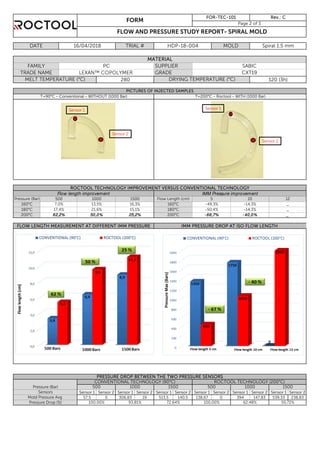

This document summarizes the results of an experiment testing a conventional injection molding technology versus a Roctool technology. The Roctool technology showed improvements including a 45% reduction in pressure drop at higher temperatures (200C) compared to conventional temperatures (90C), and flow length improvements as well as pressure drop reductions when thinner molds (1mm vs 1.5mm) were used with the Roctool technology at higher temperatures. Overall, the Roctool technology demonstrated significant improvements in flow length and reduction of pressure drop.