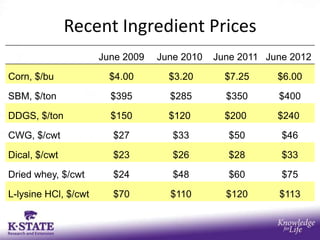

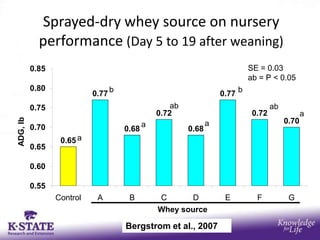

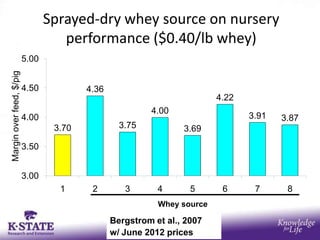

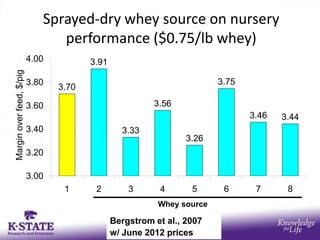

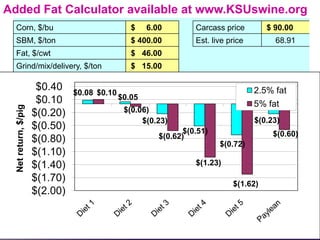

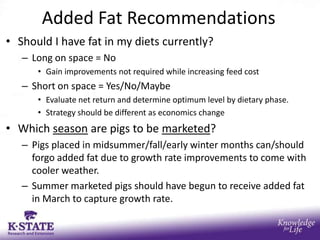

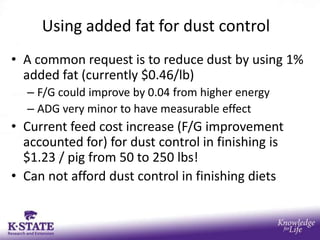

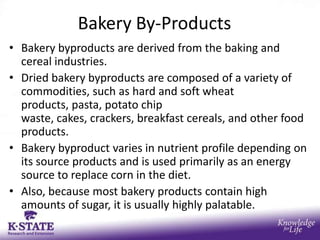

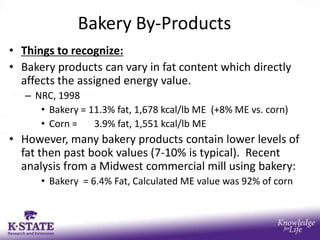

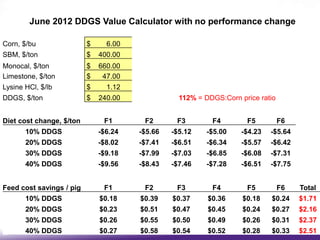

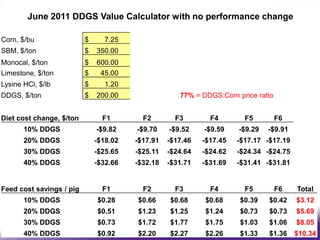

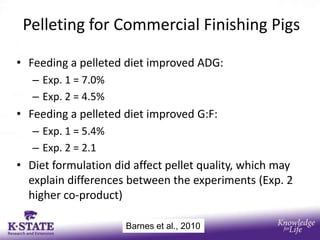

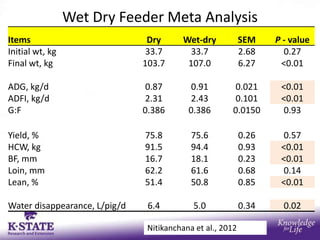

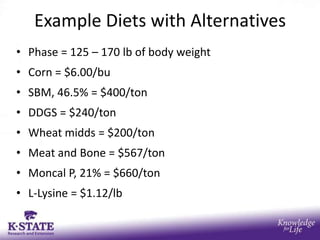

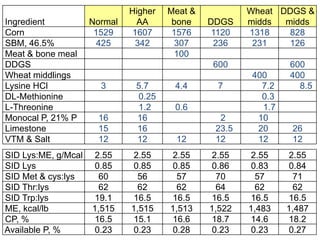

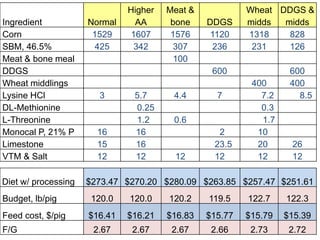

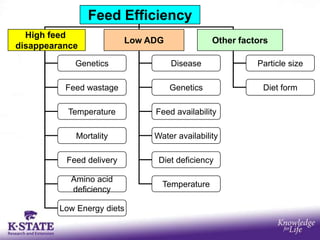

The document outlines an update on ingredient costs and their impact on swine diets, detailing changes in prices from 2009 to 2012, including corn, soybean meal, and dried distillers grains. It discusses the nutritional profiles of various feed ingredients, such as bakery by-products and the effects of different fat sources on pig performance, as well as cost-saving strategies through dietary adjustments. Additionally, it emphasizes the importance of evaluating ingredient value based on performance metrics and market conditions.