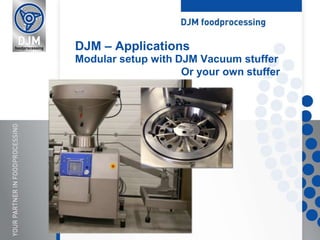

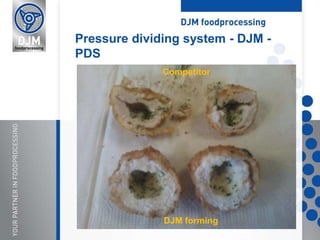

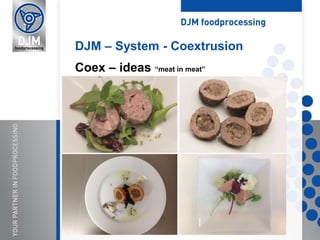

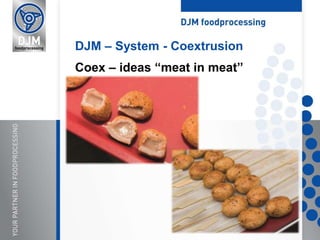

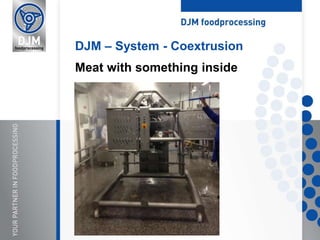

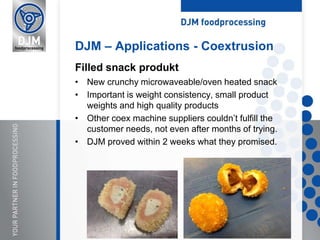

DJM is a Netherlands-based global agency with 35 years of experience in food processing, specializing in the production of a wide variety of food processing machines and systems, including coextrusion and forming technology. They focus on customizing equipment to meet clients' specific needs, achieving high weight accuracy and quality while ensuring low maintenance costs. Their innovative solutions cater to a diverse range of products, such as meats, snacks, and cheese, highlighting their capability to deliver results rapidly.