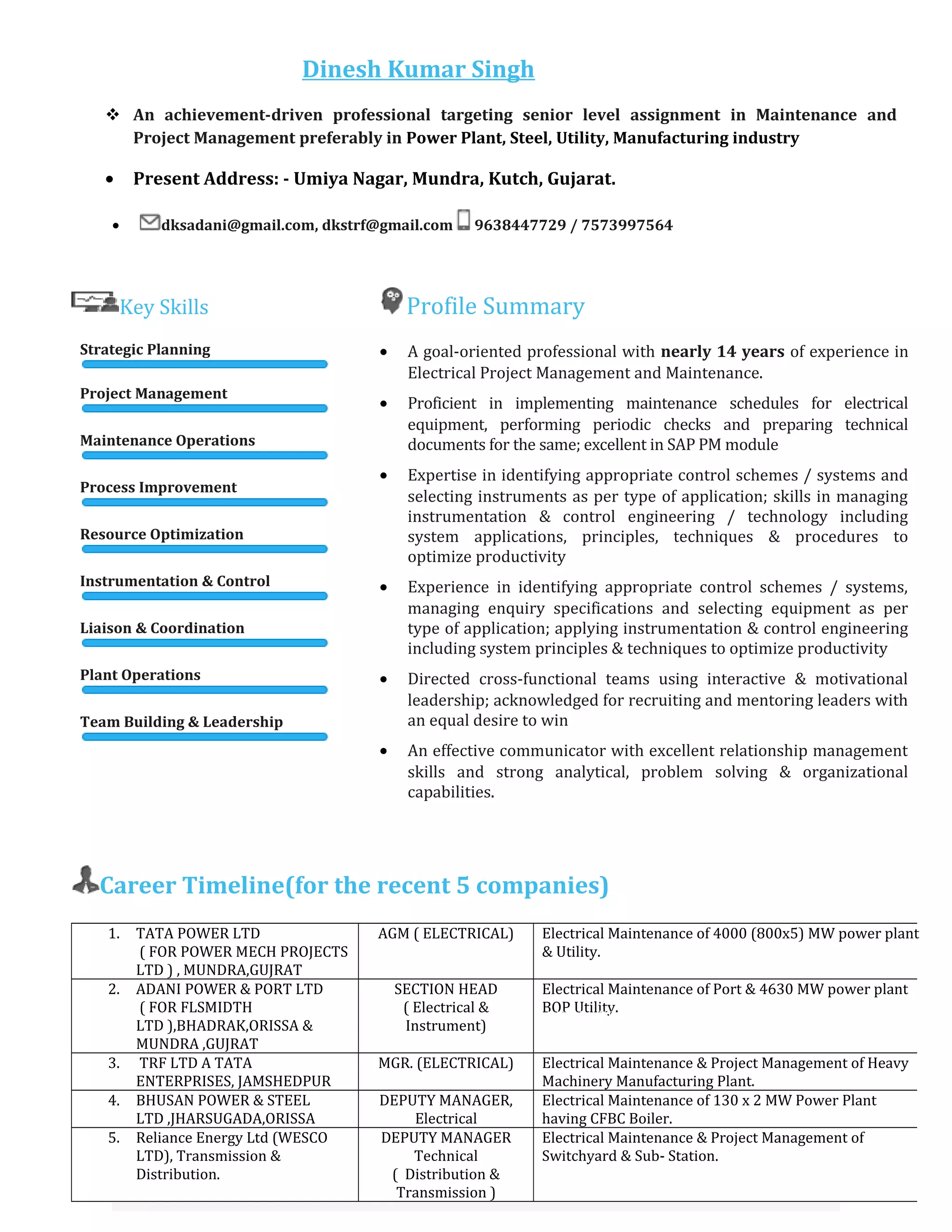

Dinesh Kumar Singh has nearly 14 years of experience in electrical project management and maintenance. He has worked in various roles for companies like Tata Power, Adani Power, TRF Ltd, Bhushan Power & Steel, and Reliance Energy. Currently he is an AGM at Tata Power where he manages electrical maintenance of a 4000 MW power plant. Some of his key responsibilities include implementing maintenance schedules, process instrumentation, and improving plant productivity and performance through measures like preventative maintenance and process improvement. He has expertise in areas like instrumentation and control, project management, team leadership, and optimizing resource utilization.