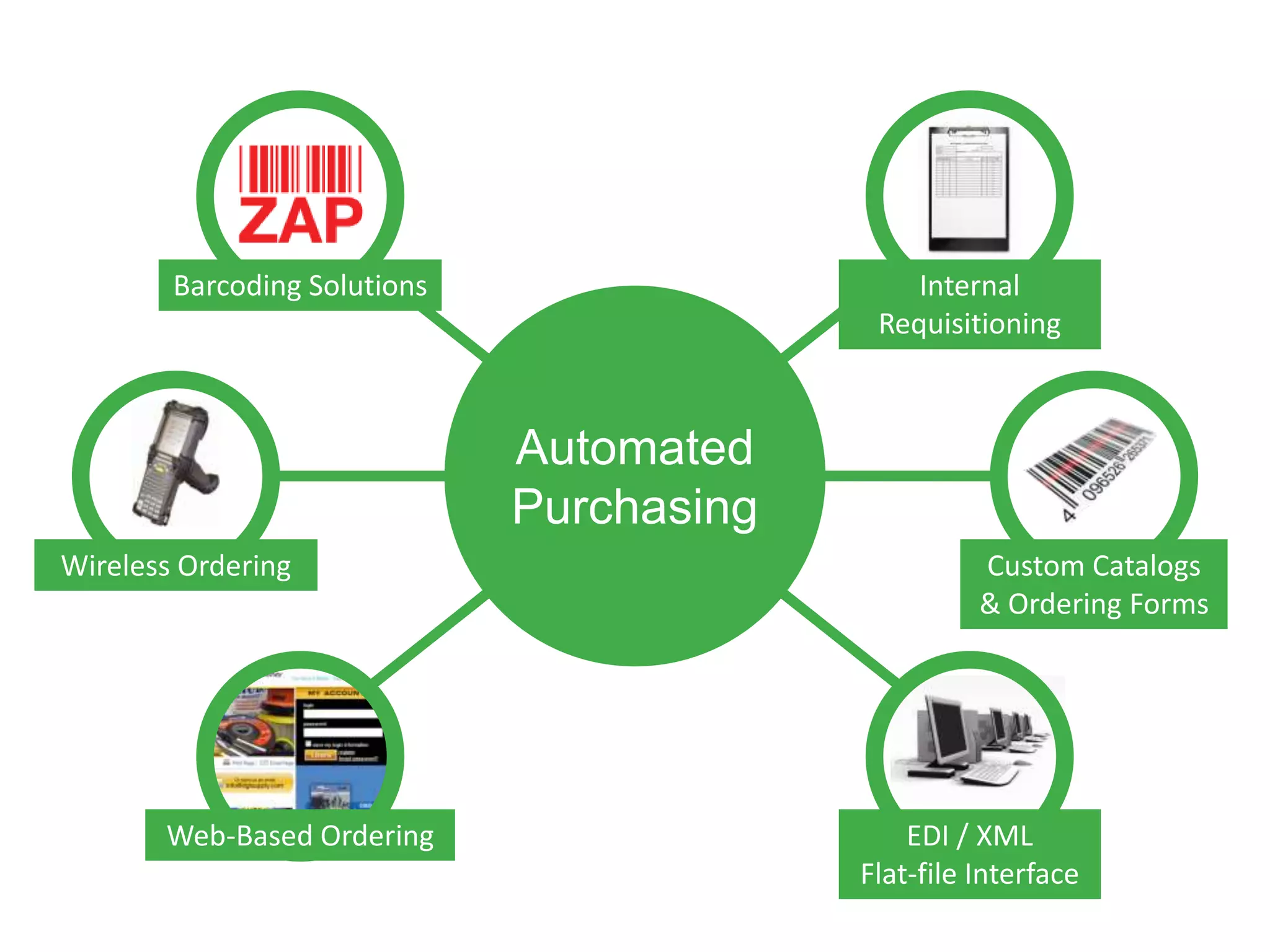

DGI Supply is a privately owned distributor founded in 1927 with over 1500 manufacturers' products in their inventory. They have over 100 customer service agents and 150 sales representatives working out of 7 offices in Canada, 37 in the US, and 6 in Mexico. DGI Supply aims to maximize their clients' productivity and save them money through inventory management solutions, automated purchasing, and process improvement services. Their capabilities include barcoding, EDI/XML interfaces, automated inventory control, and industrial vending experience. DGI Supply guarantees a 20% savings in the first year for new vending customers.