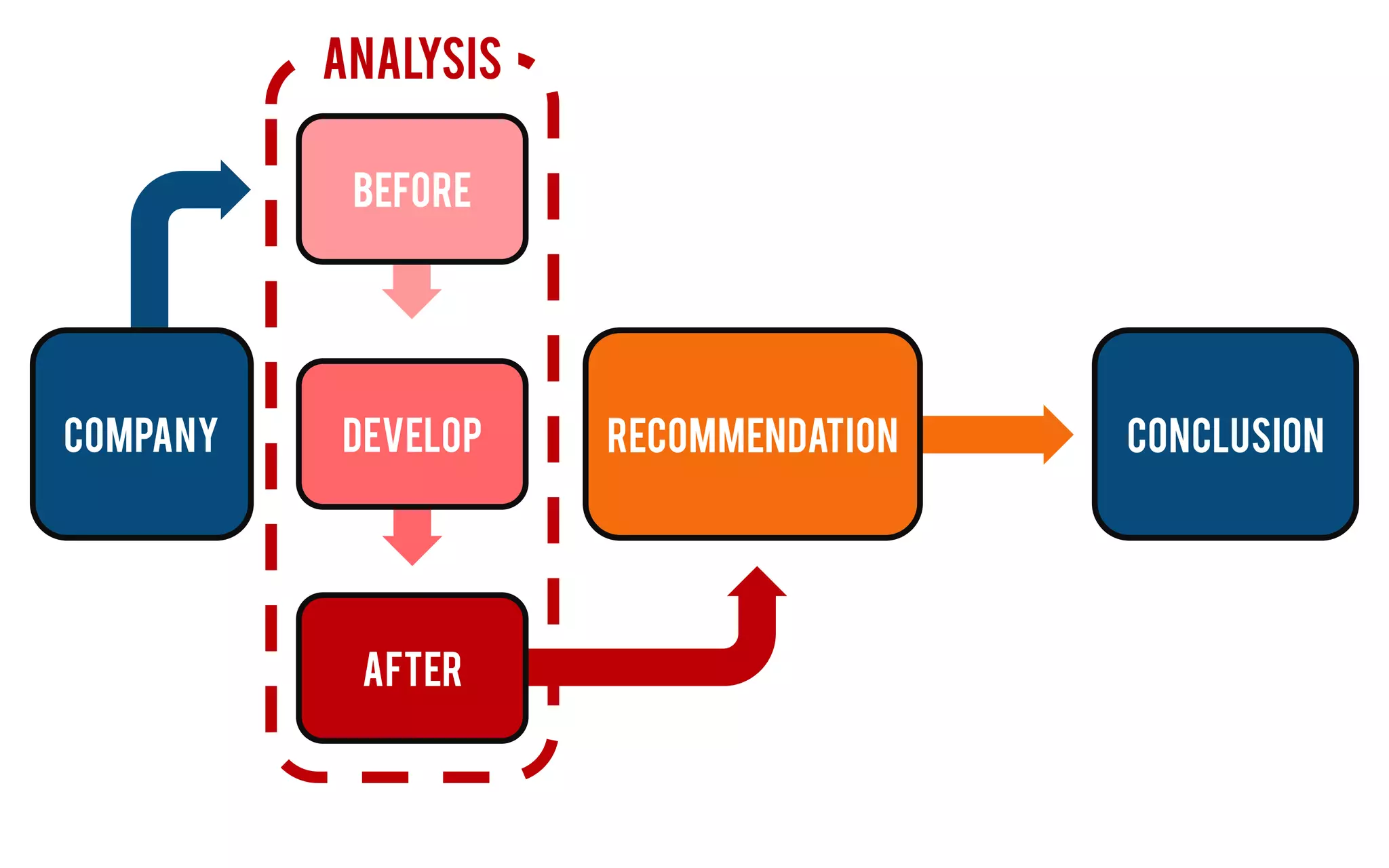

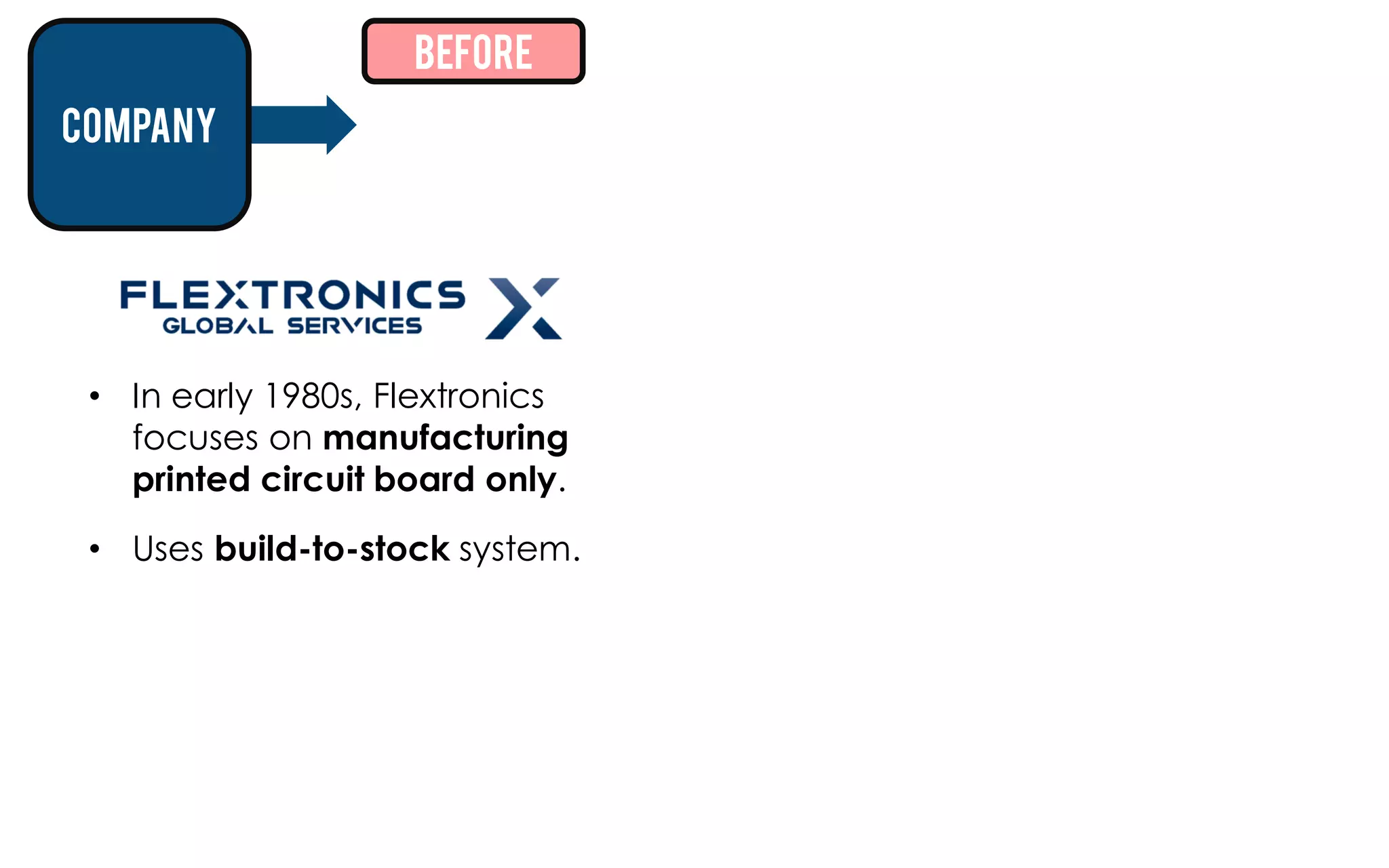

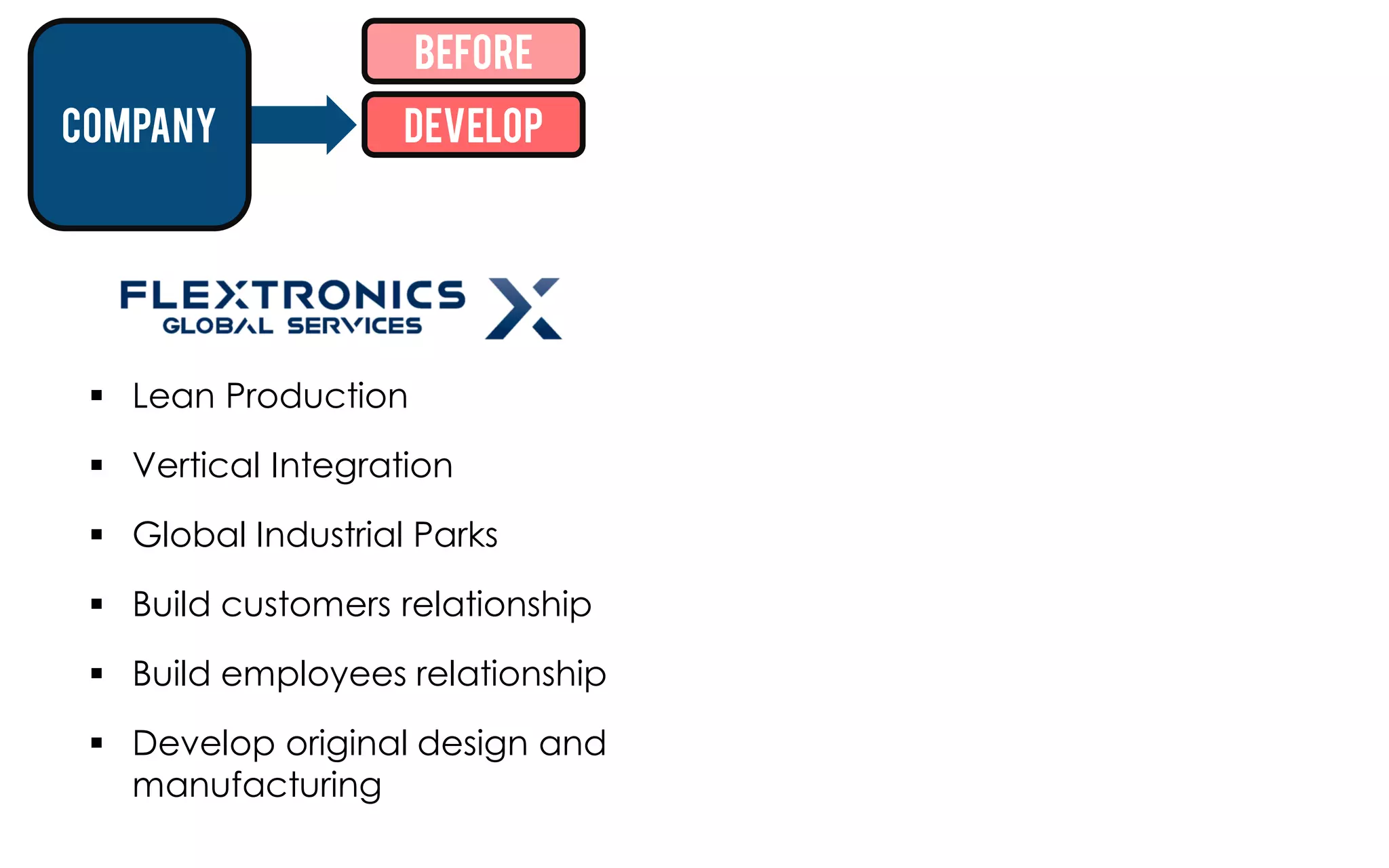

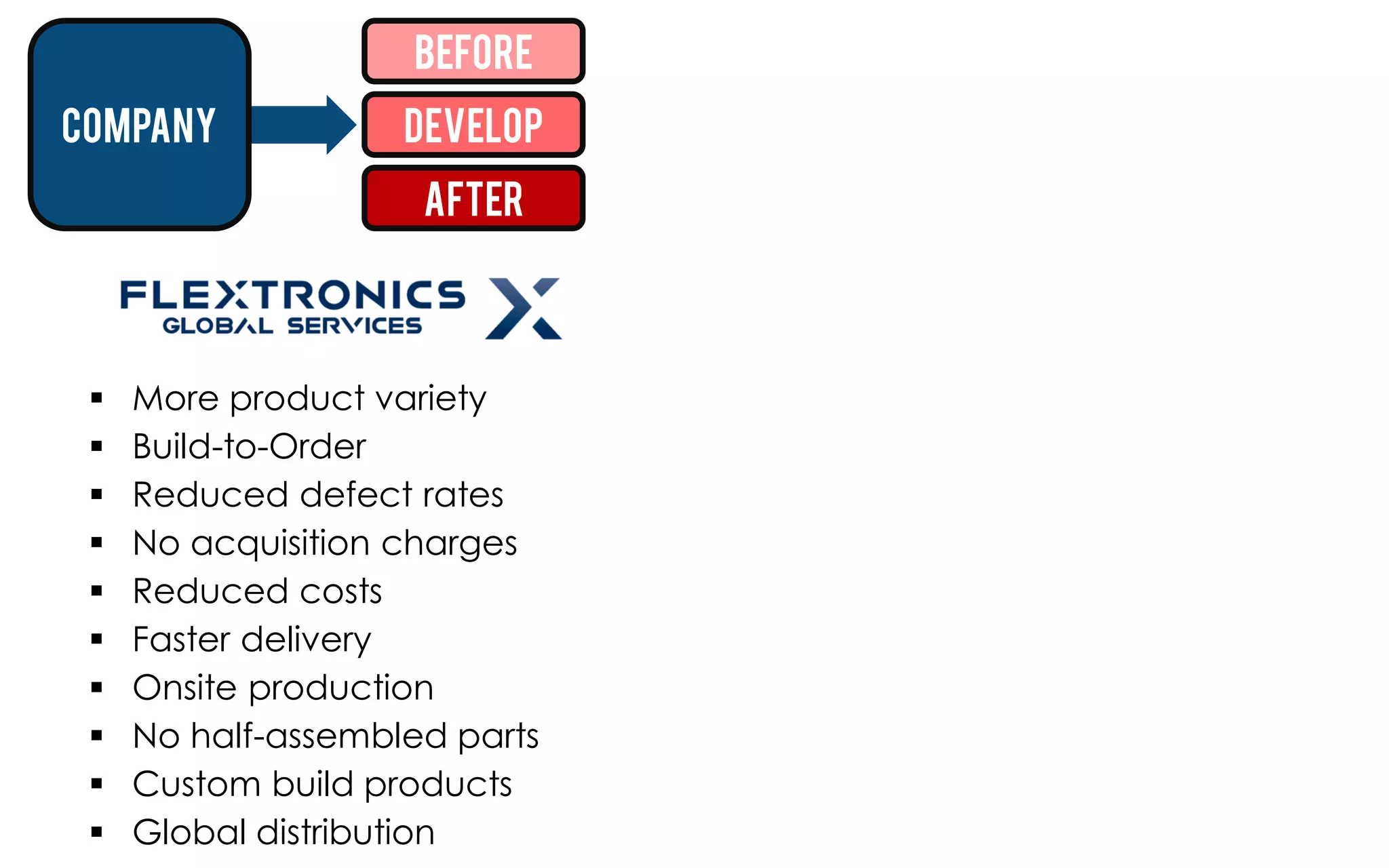

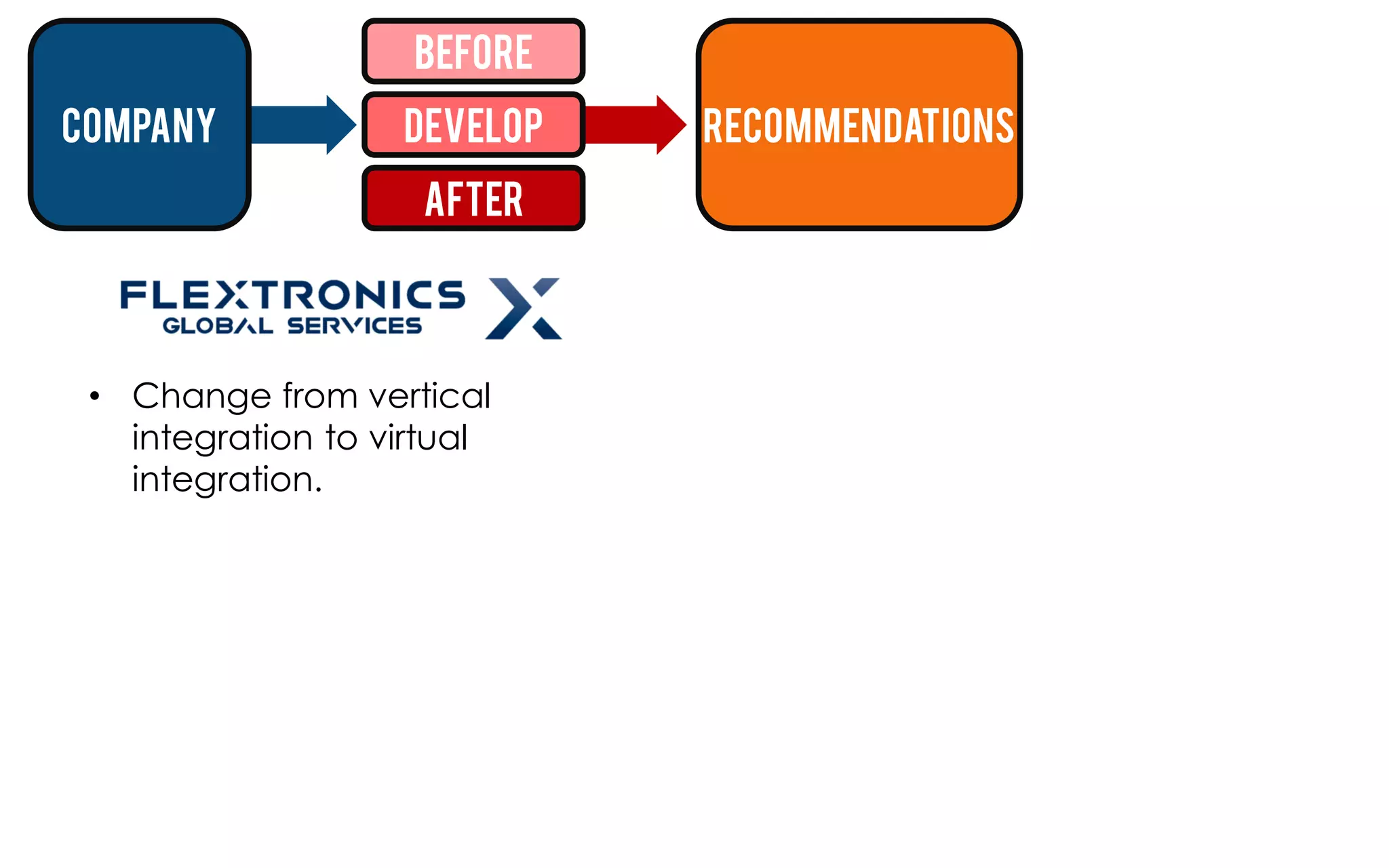

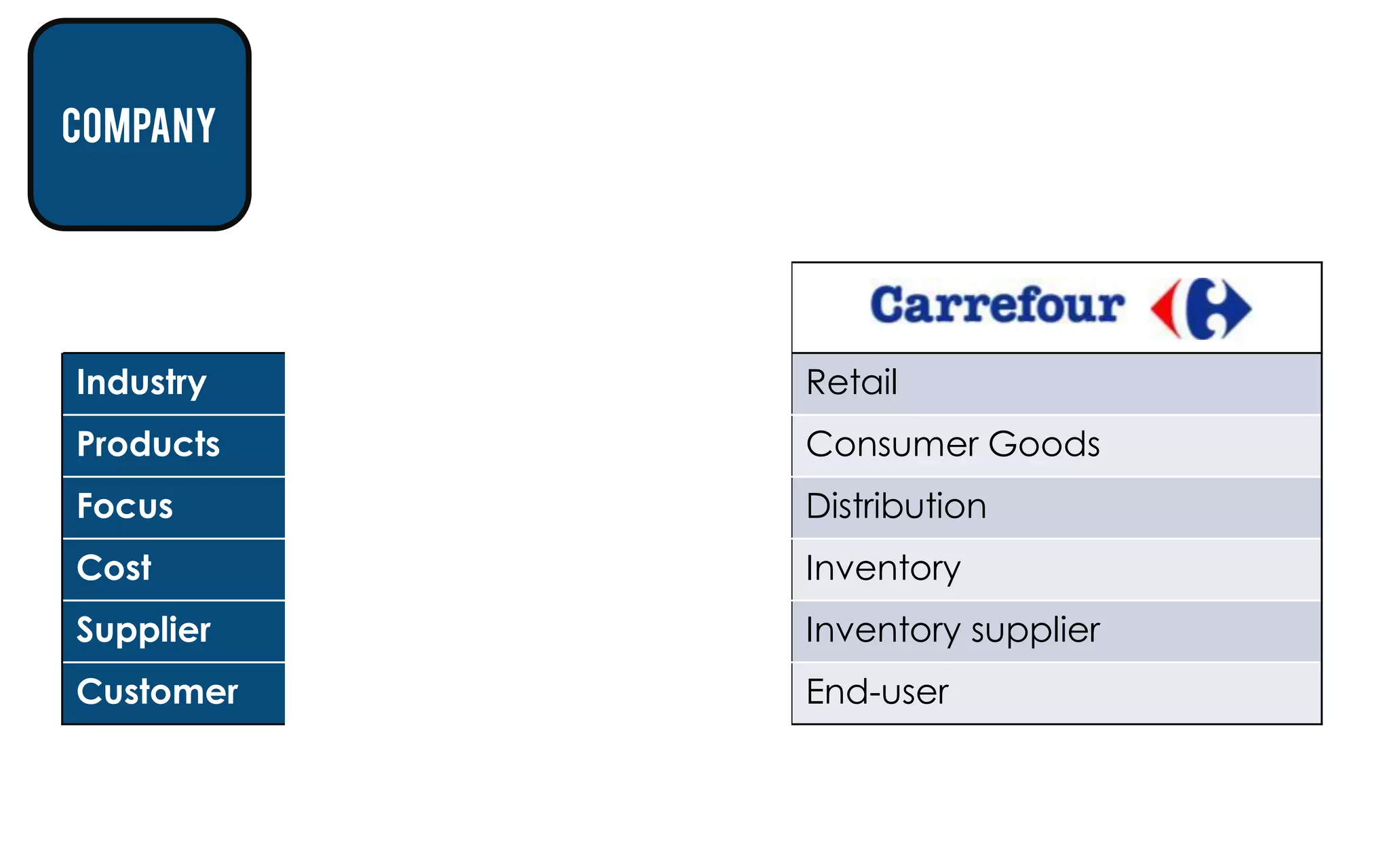

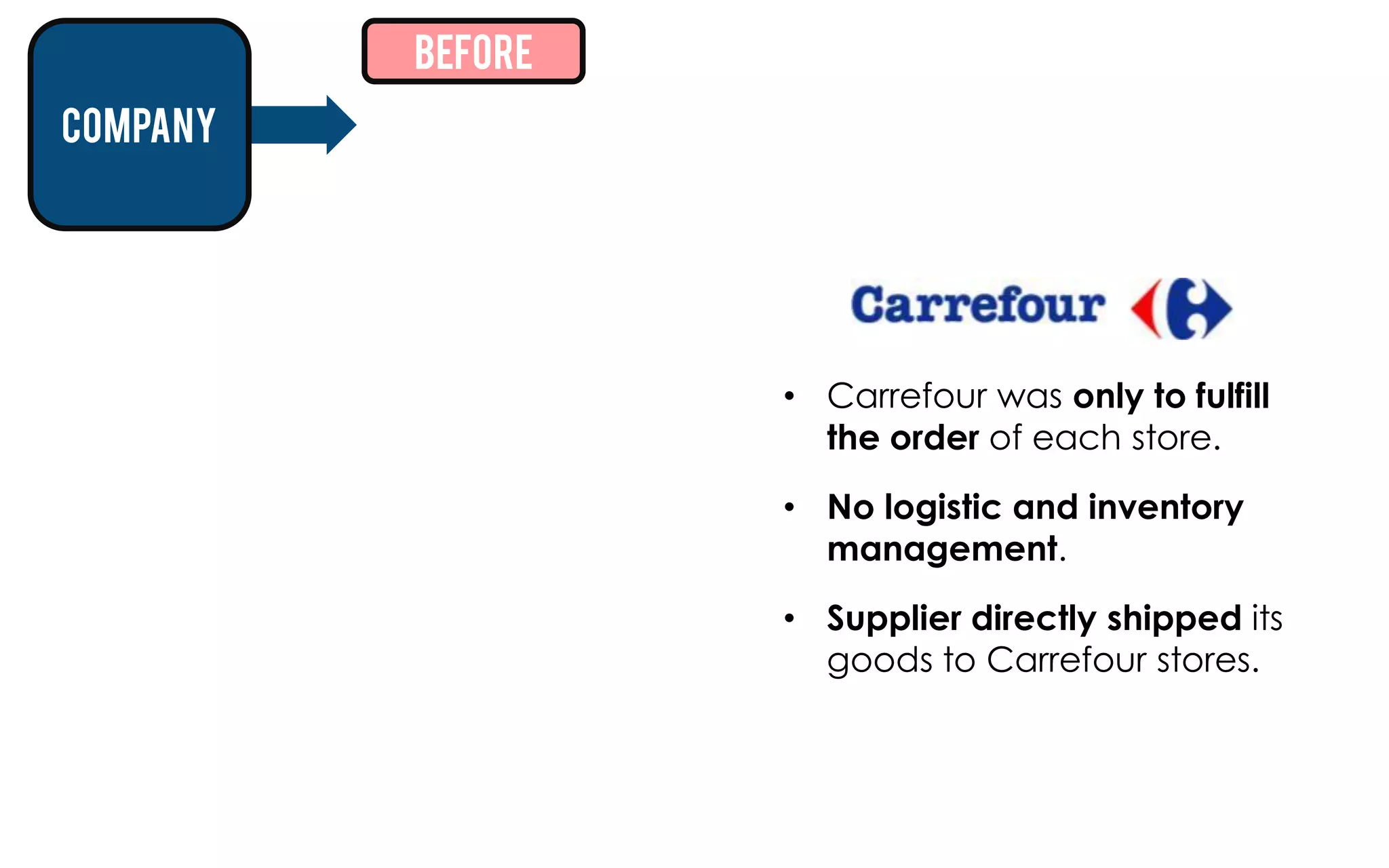

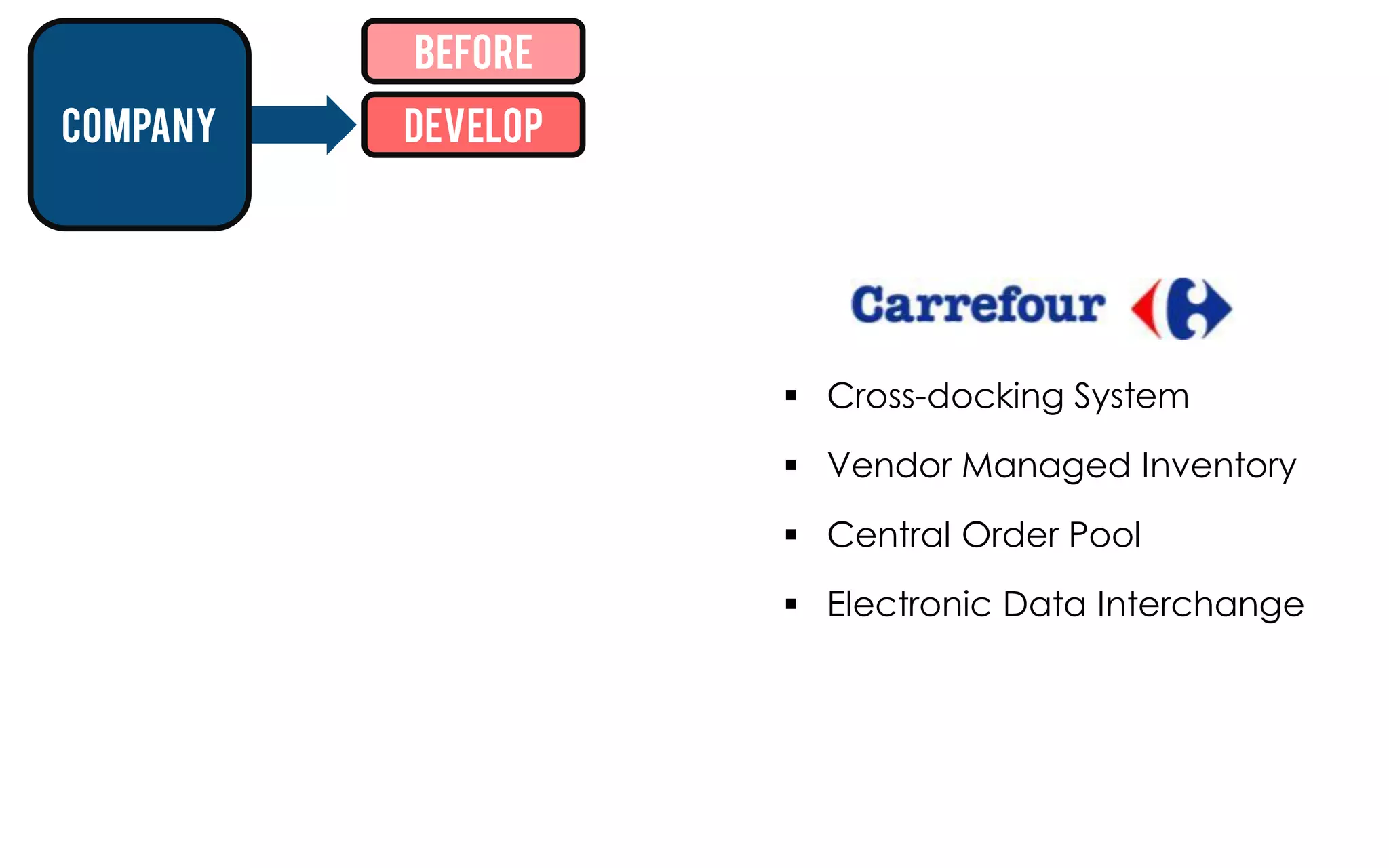

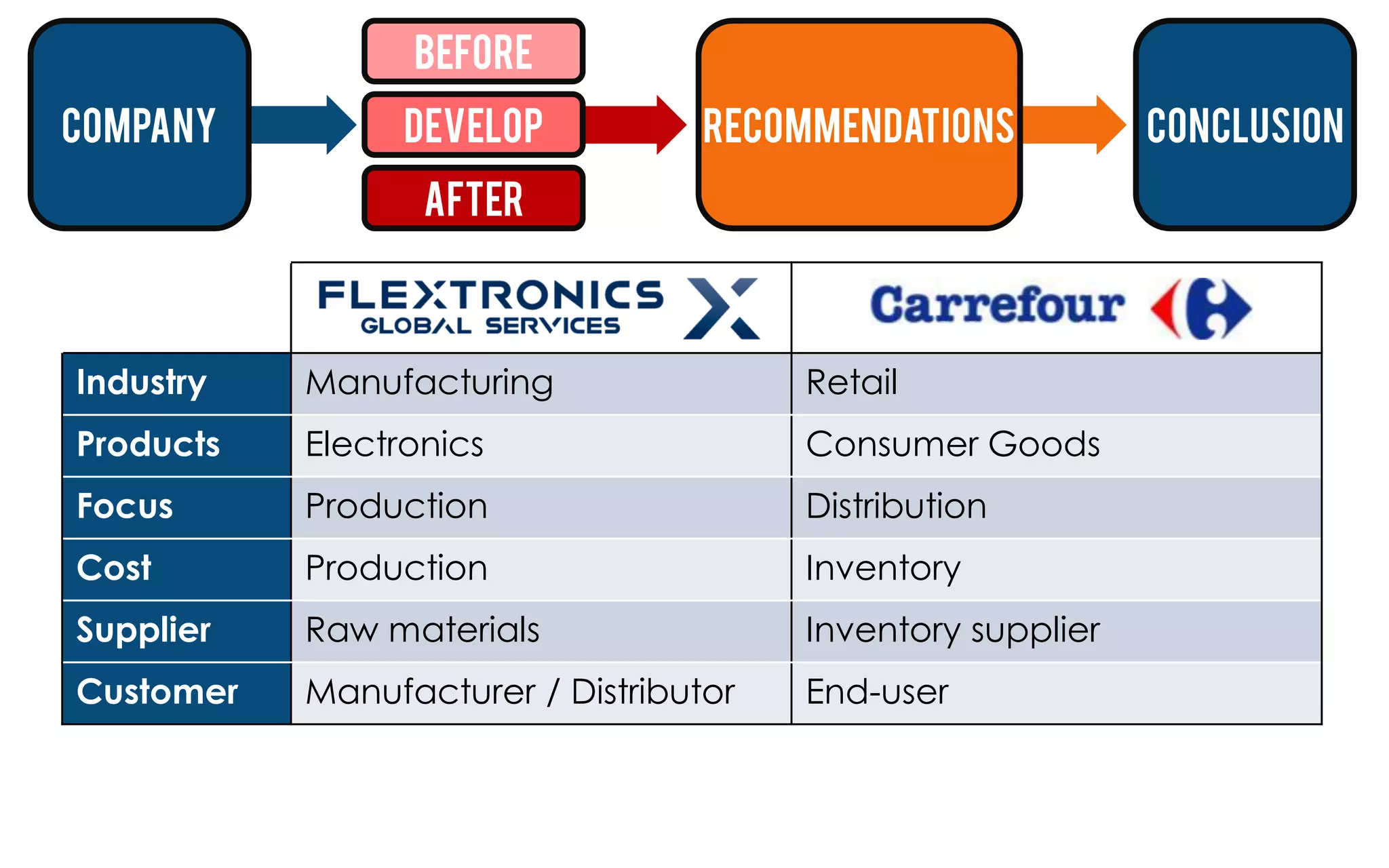

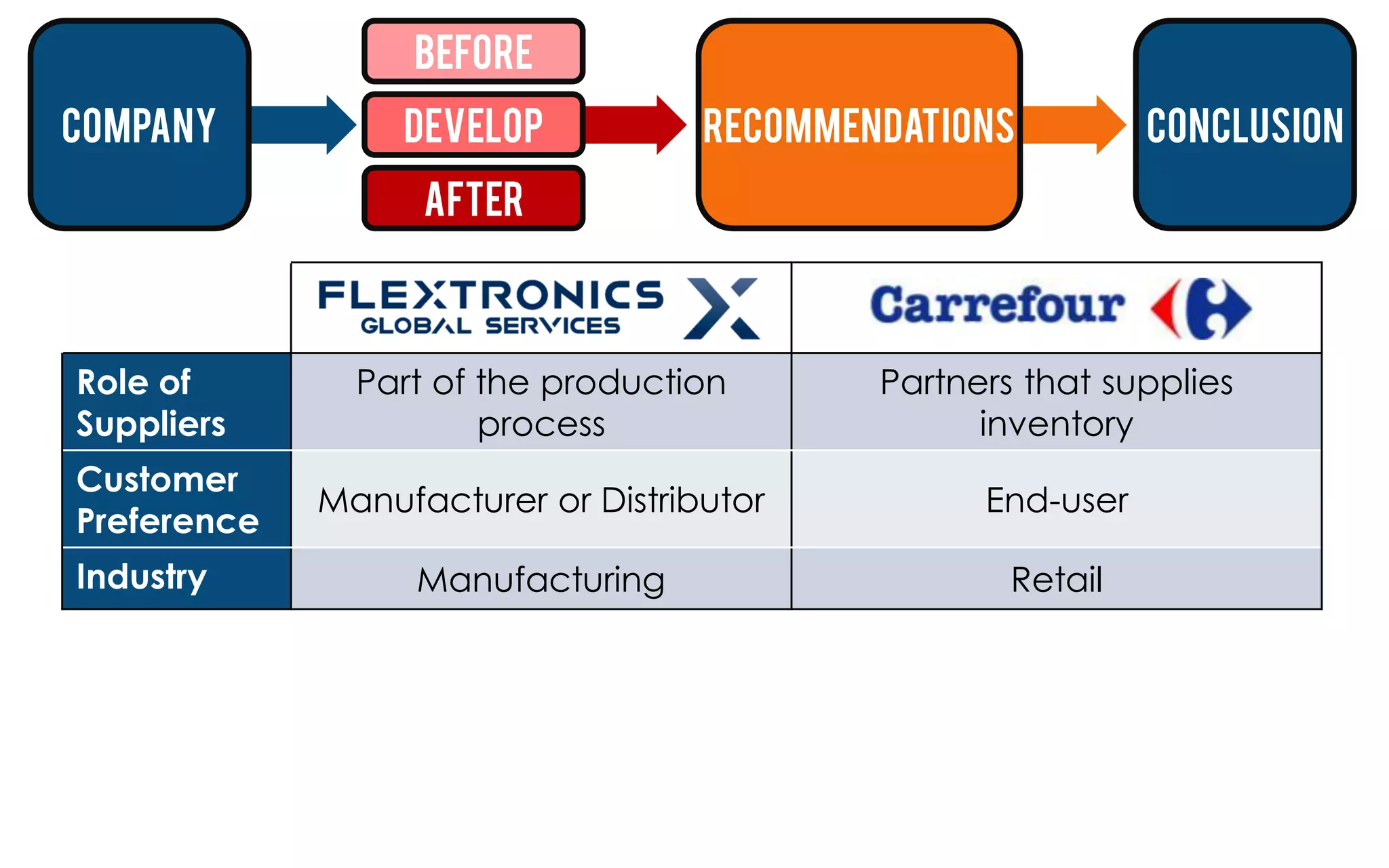

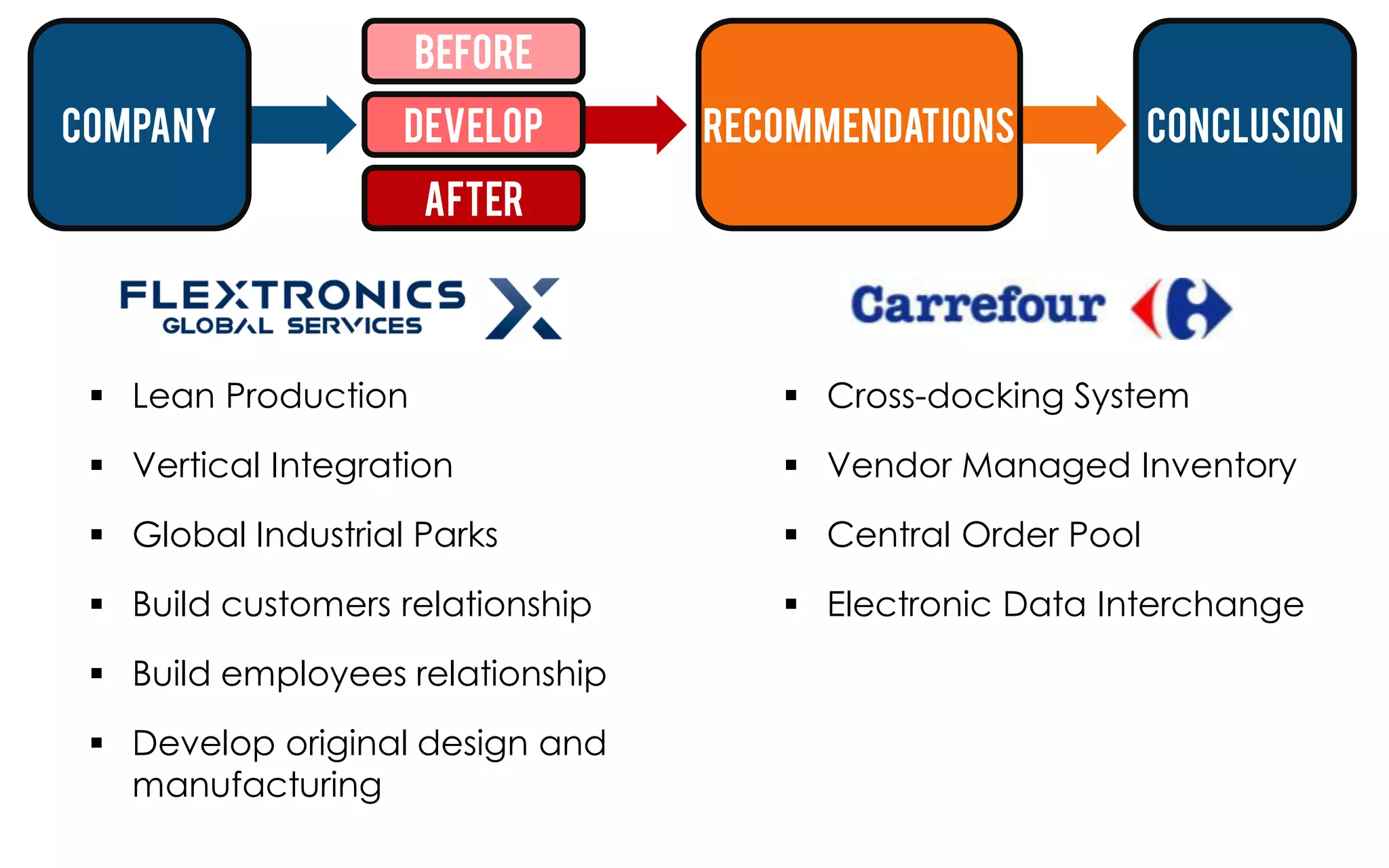

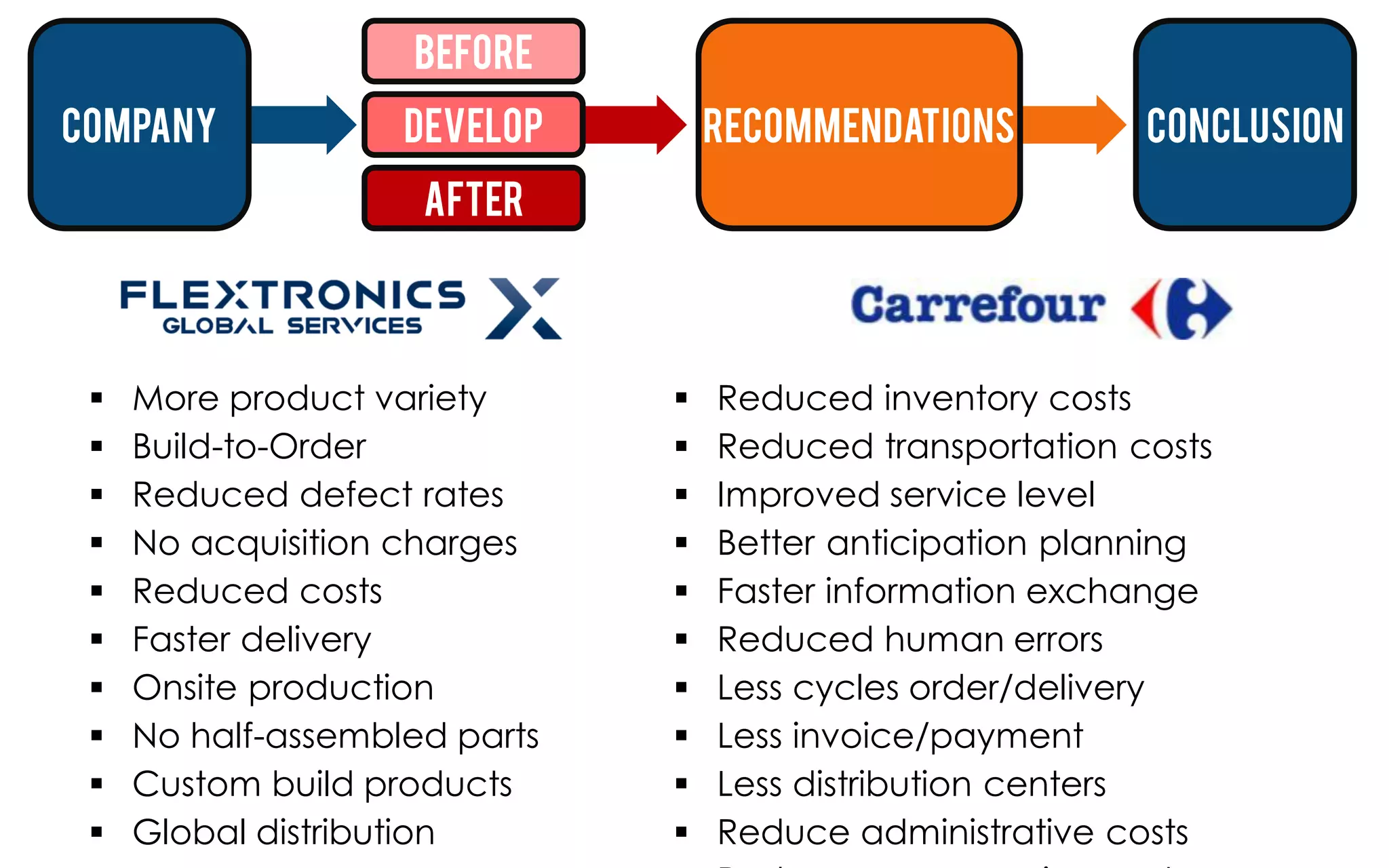

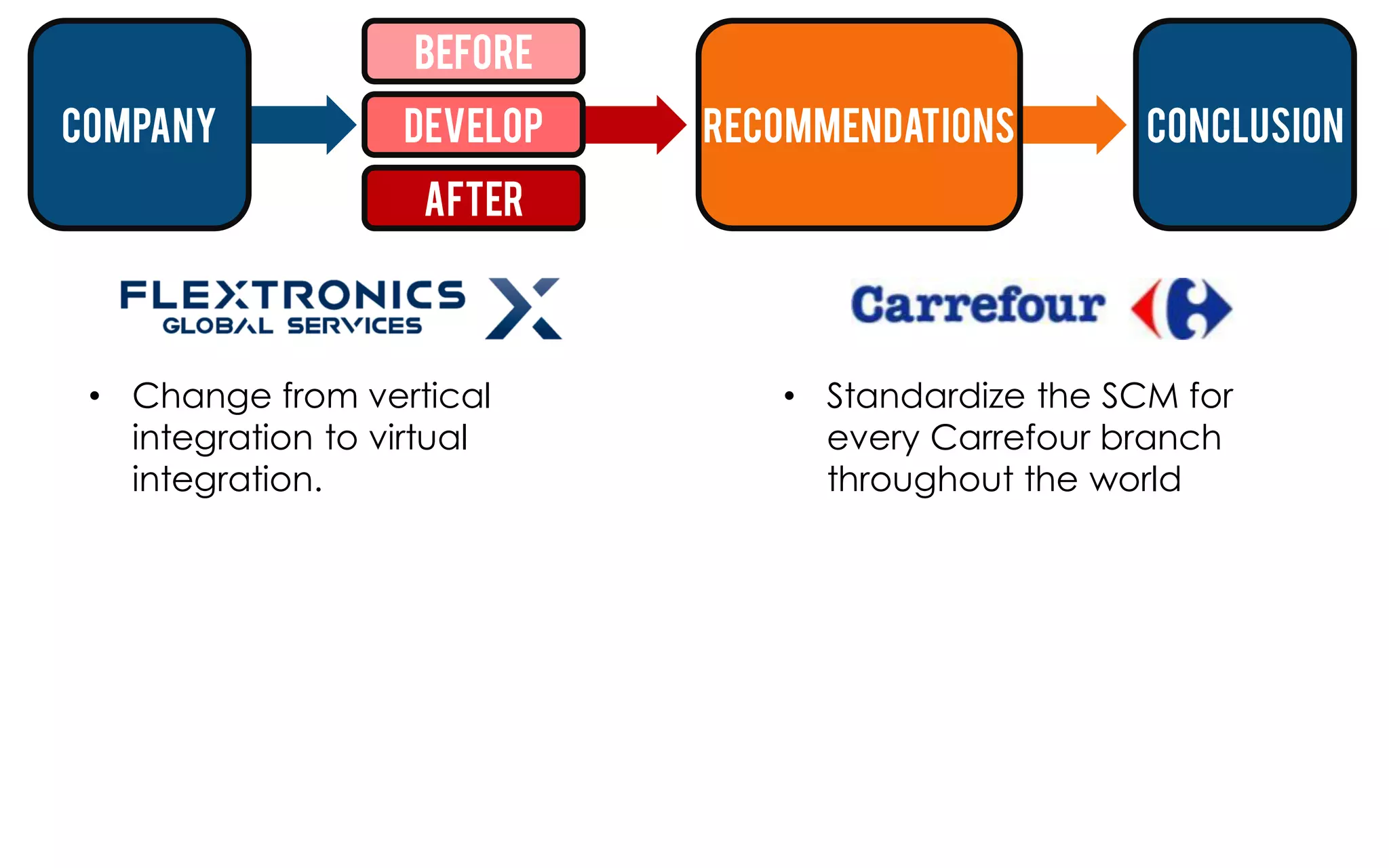

The document analyzes and compares Flextronics and Carrefour's supply chain management approaches before and after implementing changes. Flextronics focused on electronics manufacturing using a build-to-stock system, while Carrefour fulfilled store orders without logistics or inventory management. Both companies developed strategies like lean production and vendor managed inventory. This reduced costs and improved delivery for Flextronics, while Carrefour saw reduced inventory and transportation costs with standardized supply chain management.