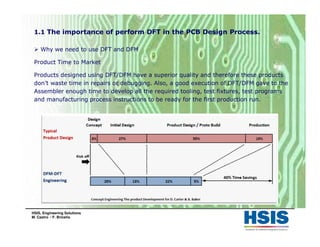

This document provides information about a 4-day course on Design for Test (DFT) and Printed Circuit Board (PCB) Design Analysis focused on testing. The course will be conducted by two instructors, Mauricio Castro and Francisco Briceño, and is aimed at design, test, product, project, and quality engineers. The course will cover DFT principles and standards, test equipment, test strategies, and include practical applications analyzing company products. Participants will receive course materials including standards for PCB design and acceptability.